Advances in Materials Science for Environmental and Energy Technologies III

Copyright 2014 by The American Ceramic Society. All rights reserved.

Published by John Wiley & Sons, Inc., Hoboken, New Jersey.

Published simultaneously in Canada.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 750-4470, or on the web at www.copyright.com . Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, or online at http://www.wiley.com/go/permission .

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Neither the publisher nor author shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our Customer Care Department within the United States at (800) 762-2974, outside the United States at (317) 572-3993 or fax (317) 572-4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic formats. For more information about Wiley products, visit our web site at www.wiley.com .

Library of Congress Cataloging-in-Publication Data is available.

ISBN: 978-1-118-99668-3

ISSN: 1042-1122

Preface

The Materials Science and Technology 2013 Conference and Exhibition (MS&T13) was held October 2731, 2013 at the Palais des congress, in Montreal, Quebec, Canada. One of the major themes of the conference was Environmental and Energy Issues. Twenty six papers from six symposia held in this theme are included in this volume. These symposia included Green Technologies for Materials Manufacturing and Processing V; Materials Issues in Nuclear Waste Management in the 21st Century; Materials Development and Degradation Management in Nuclear Applications; Energy Storage III: Materials, Systems and Applications; Nanotechnology for Energy, Healthcare and Industry; and Hybrid Organic Inorganic Materials for Alternative Energy.

The success of these symposia and the publication of the proceedings could not have been possible without the support of The American Ceramic Society and other organizers of the program. The program organizers for the above symposia are appreciated. Their assistance, along with that of the session chairs, was invaluable in ensuring the creation of this volume.

TATSUKI OHJI, AIST, Japan

JOSEF MATY, Pacific Northwest National Laboratory, USA

NAVIN JOSE MANJOORAN, Siemens AG, USA

GARY PICKRELL, Virginia Polytechnic Institute and State University, USA

ANDREI JITIANU, Lehman College, USA

Green Technologies for Materials Manufacturing and Processing

COMPARISON OF THE NANOSECOND PULSE AND DIRECT CURRENT CHARGING TO DEVELOP THE STRONGLY CHARGED ELECTRET

Keishi Awaya, Masaya Mitsuhashi, Tsubasa Sakashita, Hong Byungjin, Tadachika Nakayama, Weihua Jiang, Akira Tokuchi, Tsuneo Suzuki, Hisayuki Suematsu and Koichi Niihara

Extreme Energy-Density Research Institute, Nagaoka University of Technology, Nagaoka, Japan

ABSTRACT

Recently, micro power generation using electrets has attracted much attention due to its large power output at a low frequency range. Since the theoretical power output is proportional to the square of the surface charge density of the electret, the development of a high-performance electret is required. Conventionally, electrets have been mainly manufactured by corona discharge generated using a direct current (DC) source. However, dielectric breakdown usually occurs when high voltage is applied to a material due to the increased surface charge density of the electret. Here, we focus on the nanosecond pulse (70 ns pulse width) that has ability to apply higher voltages to materials than when DC is used. A series of measurements of surface potential and thermally stimulated discharge current (TSDC) spectra is made for various polytetrafluoroethylene (PTFE) electrets, which were manufactured by DC and nanosecond pulses. It is found that the surface charge density and thermal resistibility of electric charges are improved by using nanosecond pulses. A surface charge density using a nanosecond pulse of 0.59 mC/m2 is larger than that of using DC by 59%. In addition, the thermal stability of the electret manufactured by nanosecond pulses is superior to that of by DC. Moreover, discharge energy of nanosecond pulse generator is greater than that of DC power source. Therefore, we conclude that nanosecond pulse will be more useful for manufacturing electrets than DC.

INTRODUCTION

In recent years, energy harvesting attracts much attention all over the world1. Especially, micro power generator using electret is studied actively2, 3 Since the theoretical power output of generator is proportional to the square of the surface charge density of the electret4, the development of a high-performance electret is required. Conventionally, electrets are manufactured by corona discharge using DC power source. However, dielectric breakdown usually occurs when a high voltage is applied to materials due to the increased surface charge density of electrets. Here, we focus on the nanosecond pulse (70 ns pulse width) that has ability to apply higher voltages to materials without inducing dielectric breakdown. Nanosecond pulse has a potential to produce more strongly charged electret than DC, because it can apply higher voltage than DC to materials.

The objective of the present study is to develop a fabrication method for a new electret using nanosecond pulse for higher surface charge density and thermal stability.

EXPERIMENTAL

Nanosecond pulse power source

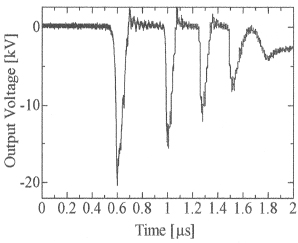

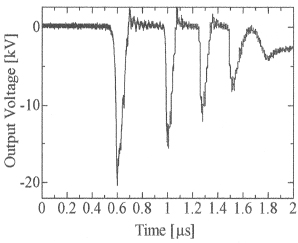

shows output wave pattern of a nanosecond pulse generator. Nanosecond pulse discharge generates an extremely short pulse width and because the voltage falls before the generation of insulation breakdown, which is induced by the application of a high voltage, it is possible to apply the higher voltages than when DC is used.

. Output wave pattern of nanosecond pulses

Electret manufacture

Electrets were manufactured by applying a high voltage to a needle and injecting ions using a corona discharge under condition given in . 6 kV DC is the maximum voltage that can be applied to the sample without being damaged.