Contents

Preface

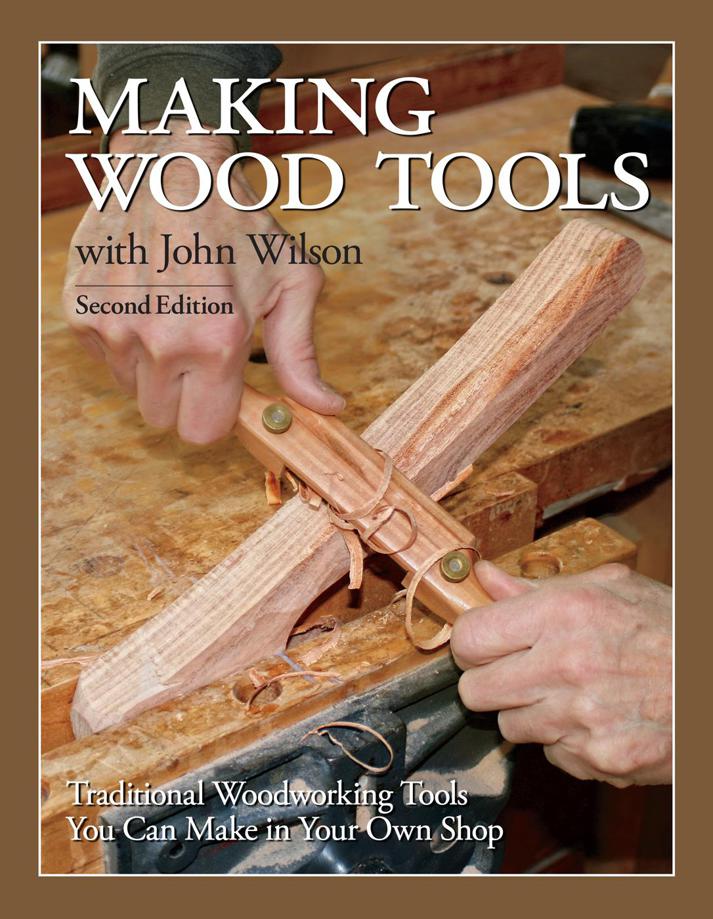

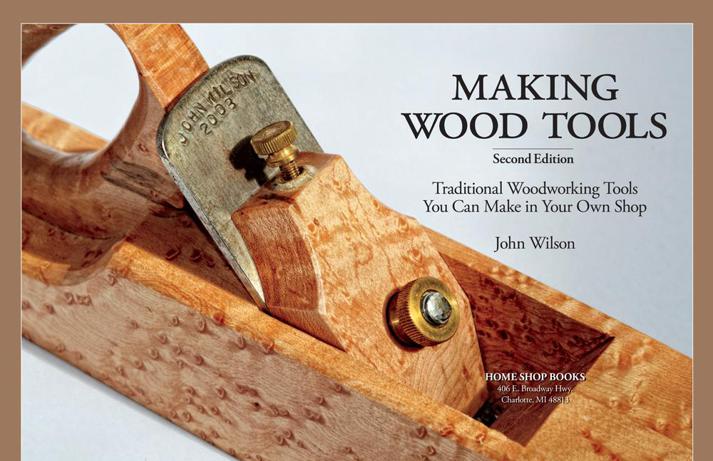

R estoring our tool making heritage involves both design and construction of the tool body as well as the making of the blade. This book takes the mystery out of both. Those familiar with the First Edition will find modification to several tools as well as the addition of new ones. The hand adze is improved with added head weight and the spokeshave with a sole plate to protect from wear.

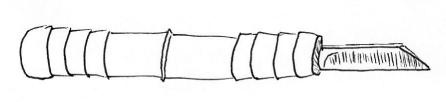

The new shoulder plane lends itself to a mortising plane for hinge gains, a rabbeting plane, and molding hollows and rounds. The simplicity of construction commends it as an undertaking early in your tool making venture into these specialty activities. The large compass plane builds on the scrub plane platform to give you the ability to hollow a Windsor chair seat or similar indent. And if you want a first project in using dimensional tool steel look no farther than the carving and layout knife.

Using O1 dimensional tool steel is new ground for many woodworkers. The availability of a variety of dimensions at reasonable cost is the beginning. Knowing about heat treating is what makes it useful. It is reassuring to learn that O1 tool steel remains as fine a steel as any available for the woodworker. The following is a conversation with a knife maker:

In SEM monographs comparing the grain structure of popular knife steels, O1 had the finest grain structure by far. In practical terms it means the O1 can be made sharper than other steels. Other steels have larger carbides and can make an edge that lasts longer in terms of wear, but can never be as sharp. Another attribute of O1 is that heat treating has more latitude and is easier to get good performance out of low tech processing .

The path to a fine tool can take many routes. What you will find here is my encounter with shop made tools:

Using means of construction readily available in the wood shop

Using means of construction readily available in the wood shop

Breaking down the construction into understandable steps

Breaking down the construction into understandable steps

Simplifying each step to ensure success

Simplifying each step to ensure success

Having the journey give you ownership in the fullest sense of a tool you can use.

Having the journey give you ownership in the fullest sense of a tool you can use.

The Home Shop

P.S. Besides new projects like the Carving & Layout Knife shown below (see .

Introduction

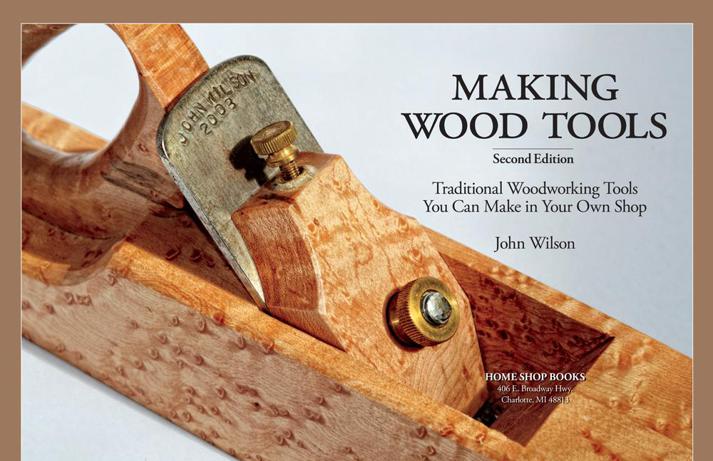

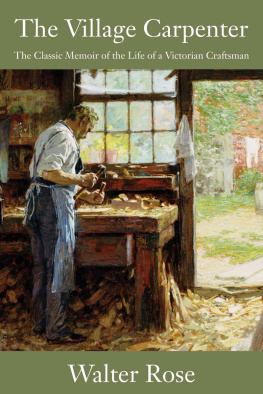

T he projects in this book represent tools you can make. These are not the electric stationary or portable tools prominent in most shops in the 21st century. They are the legacy of the 18th- and 19th-century craftsmen that are being rediscovered by woodworkers today. While the majority of my day is spent with a fractional horsepower electric motor in my hand or turned on before me at a saw, my life in wood is immeasurably enriched by knowing about these tools and knowing where to reach for them when the task calls for it.

Tools represent a state of mind. Their use and range of application depend on the skill of the hands that reach for them and put them to use. Whenever you see an application for another tool, that is the time to make or buy it. This is more than collecting. It is using the tools of the trade.

Dont balk at the price of a hand tool. For some reason we think they should be cheaper than their power equivalent and yet hand tools last immeasurably longer. My grandfathers hand tools are as good and useful today as they were in the 1860s when he learned to use them.

By the 1960s much of this legacy had been lost to Americans, both the mindset to use hand tools and the sources of supply where they could be found. It is one of the success stories of woodworking in our lifetime that this trend was reversed. Forums for good information were started and two of the first were Fine Woodworking (1975) and WoodenBoat (1974). I remember the first time I received the Garrett Wade catalog. What a feast for the eye and an invitation to explore. Two catalog sources from hand tool designers and manufacturers are very much alive today and come out of this revival: Lie-Nielsen Toolworks (.

Magazines, books, film, schools, and wood shows have proliferated in the period since the beginning of this tool revival. It is said that wood working ranks along with gardening, cooking, and reading as Americas favorite pastimes. Magazines like Popular Woodworking Magazine, American Woodworker and Wood serve their interests and serve them well. Ernie Conover, Marc Adams, and Kelly Mehler come to mind as individuals whose knowledge and passion for fine woodworking and tools have led to opening schools. The Home Shop, my own business for supplying craftsmen with oval box supplies, holds classes where all of the tools featured here have been taught, and whose students served as proving ground for what you read.

So why make your own tools? Some do it to save money. Others for the challenge to learn how. I would add that a tool is more than itself, it is a mindset. This makes tool making an enlightening experience, and a legacy to give your grandchildren.

Making Planes & Other Tools

Next page

Using means of construction readily available in the wood shop

Using means of construction readily available in the wood shop