Yes You Can Do It!

When you get started in woodworking there are many paths to follow, forks in the road, dead-ends and shortcuts. Its a journey that our forebears would make with the help of a living, breathing guide: a master, a grandfather, a shop teacher.

Sadly, the guides are fewer in number today. And so you are left with people like me to help. Like the making of meat by-products, its not a pretty sight. Getting your woodworking instruction from books, magazines, television and the occasional class is a slow way to learn a complex task. In fact, many woodworkers spend a long time (years!) simply accumulating machines and tools before they ever build a single piece of furniture. And when they do begin to build, they inevitably discover that they actually need different machines and tools to make what they really want to make.

So they buy more tools and machines.

I want you to know something important that doesnt get said much: There is another way to begin building furniture. You dont need a table saw, a workbench or even a shop. You dont need to spend $1,000 to build your first birdhouse. You can go to the home center in the morning and start building something the same day.

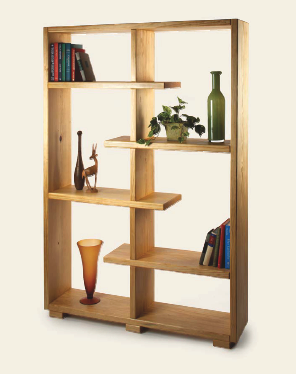

Im not talking about building junk, either. The difference between a nice-looking set of bookshelves and a rude assemblage of 24s isnt a table saw. The difference is cleverness, sound design and just a wee bit of patience.

To build nice furniture you need a handful of decent tools that you wont outgrow. This book will help you select the right tools that strike a balance between price and function. You need to use these tools correctly; well show you how to use them to build furniture (something you rarely find in the instruction manual). You need a place to work; a driveway, garage or corner of the basement will do nicely. You need good materials; well show you how to get everything you need from the local home center. And you need plans and ideas for things to build that look nice and can be constructed with these tools, methods and materials.

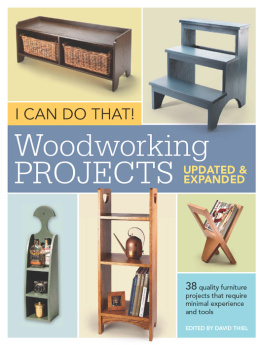

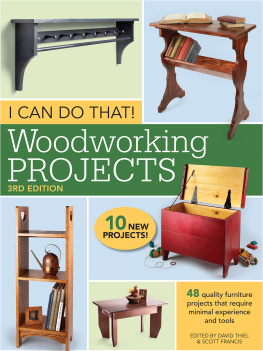

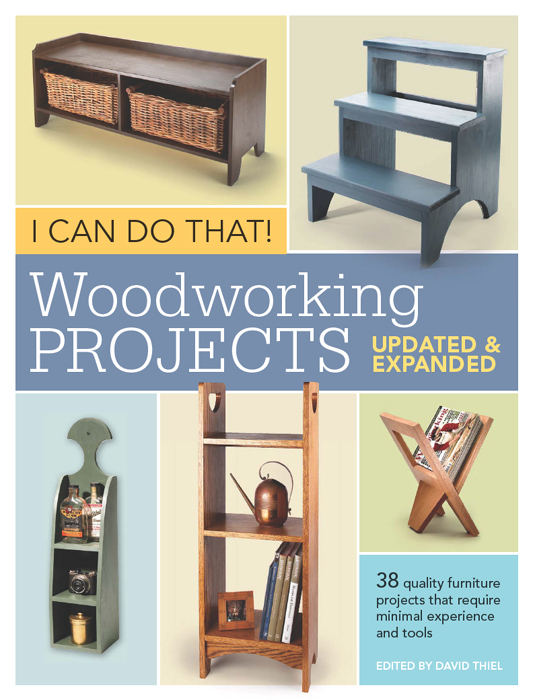

In every issue of Popular Woodworking magazine we publish a column called I Can Do That because we want readers to say that (out loud or in their heads) when they read the magazine (and now this book). Weve offered many of the plans used in the magazine and have added another ten, built specifically for this book and for you.

Eventually, we think youll outgrow the manual part of this book (and on the web at www.icandothatextras.com) as your skills improve. I bet you will want a table saw someday. And a drill press. And a smoothing plane. When that day comes, however, youll also have a house full of well-proportioned, well-built projects under your belt. You will be ready for those awesome tools, and the learning curve will be mercifully short.

If all this sounds like something that a bunch of idealists cooked up at a corporate strategy meeting, youre wrong. Though I had some carpentry training from my father and grandfather, I started building furniture on my back porch in Lexington, Kentucky, with a very similar set of tools. Probably the only major difference is that I had a circular saw instead of a miter saw (I didnt know those existed yet). I built a lot of stuff with my simple setup some stuff we still have today and some stuff that was long ago abandoned at the curb or given away.

So this, dear reader, is a valid path.

My only regret in following it is that I wish Id had this book (or a master) to make the journey easier.

Christopher Schwarz

Contributing Editor, Popular Woodworking Magazine

Rules for Using

the Tools

BY CHRISTOPHER SCHWARZ AND THE POPULAR WOODWORKING MAGAZINE STAFF

The pioneers cleared the forests from Jamestown to the Mississippi

with fewer tools than are stored in the modern garage.

unknown, attributed to Dwayne Laws

Im not an emotional guy. I dont get nostalgic about high school, my first car or my first dog, Scampy. I dont much hug family members at holiday gatherings. But I do have the deepest respect and affection for my tools. The care you give tools will gush readily into the things you build with them. None of the tools in the following kit are disposable; if you take good care of them, they will be around for many years of service.

STOP RUST

Here are some basic tips for caring for all tools. Dont you dare let them rust. Rust spreads like a cancer in ferrous materials (iron and steel) and can make your measuring and cutting tools difficult to use. There are a lot of products out there to prevent and remove rust, but the best thing going cannot be found on the shelf: a small can of vigilance.

When you are done with a tool, wipe down the metal surfaces especially the cutting surface with a rag that has been soaked with WD-40. Always keep the rag nearby (mine is seven years old) and renew it with a squirt of WD-40 when it gets dry. Wiping your tool down does two things: First, it removes dust from the tool. Dust can carry salt. Salt attracts water. The combination of salt and moisture will start breaking down your iron and steel tools.

Second, the WD-40 helps prevent rust by forming a thin protective barrier, albeit one that must be constantly renewed to be effective. Other people will disparage WD-40 (I once did). Ignore them. We tested all the rust preventative products on the market one spring weekend. We applied the products to a cast-iron plate and left the plate outside in the dewy grass for a couple of days. The area treated with WD-40 came out of the test looking the best. WD-40 is cheap. Its readily available. It wont stain your work. Spray some on a piece of wood and watch what happens. Once it dries, theres nothing to see.

LEARN TO SEE

All of your tools require tweaking and maintenance. They might work perfectly right out of the box; they might not. It all depends on who made the tool and what sort of day they were having when your tool came down the assembly line whether the assembler was a robot or a person.

You need to learn to set up your tools so they do what they were intended to do cut square, bore straight holes, measure accurately. Once you set them up, you need to check on them every once in a while. Trust, but verify. Its a fact: Tools lose their settings after regular use.

In fact, one of the biggest challenges in woodworking is training your eye to see the right things. You need to learn to see if the cut is square. You need to see if your square is square. Have you ever heard the old expression tried and true? It is an expression that applies to your tools as well as your work. When you make a cut you should test it to make sure its the cut you wanted this is called trying your work. If the cut is correct it is said to be