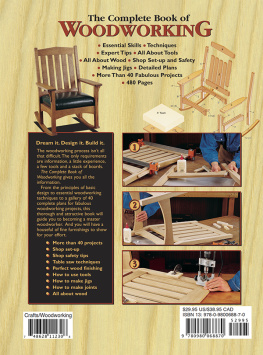

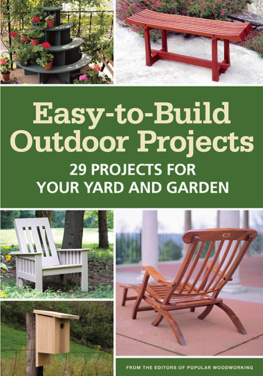

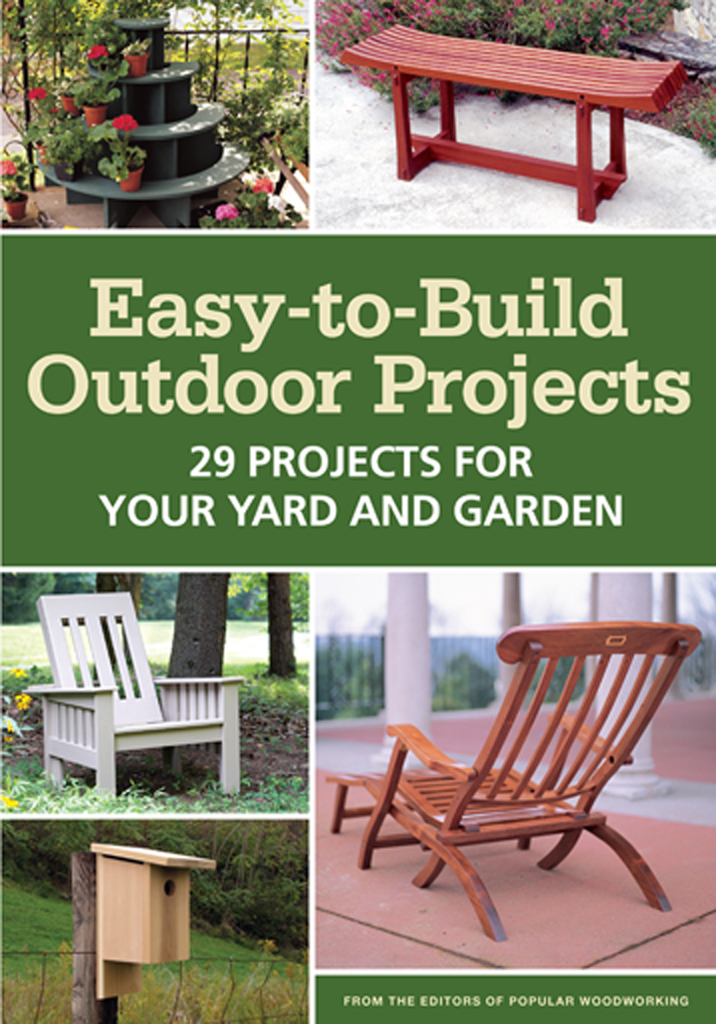

Easy-to-Build Outdoor Projects

29 PROJECTS FOR YOUR YARD AND GARDEN

From the Editors of Popular Woodworking

Cincinnati, Ohio

www.popularwoodworking.com

Introduction

Outdoor can mean something different to each individual. My outdoor may be a wooden deck overlooking a lake. Your outdoor may be 20 acres of wooded land, while another persons outdoor may be the high dessert with a yard of stone and cactus. Its not only the topography that changes, but when the outdoor can be enjoyed its a big country, and our seasons dictate when we can appreciate nature one-on-one.

Beyond these variables, we humans do have an affinity for the great outdoors. Interesting that civilization seems to be built on creating ways to a us from nature (bigger houses, air conditioning and technological advances to keep us inside and busy), but we still retain our love for the outdoors, enough so that many of our vacations are built around getting back to nature and viewing the natural world. And thats why we continue to value the outdoor that is right in our own backyard. While we all enjoy nature, we also tend to want to adapt it for our personal use, and thats where the projects in this book come in.

Weve collected a selection of projects, ranging from seating to bird feeders, with a few other odds and ends tossed in. There are no decks or pergolas thats a different book. Most of the projects require significantly less time, money and experience to build than a traditional furniture project allowing you more time to enjoy the finished work and your outdoors. All the projects include detailed instruction, illustrations and material cutting lists to build the projects as shown, though we always encourage personalization. Dont hesitate to make changes. Thats what building your own is all about.

We hope you enjoy the book, enjoy the projects (both the building and the using) and enjoy the great outdoors!

David Thiel, editor

PROJECT 1

Garden Swing

by David Thiel

When lunch is served at the garden swing, simply pop up the center section of the seat to turn it into a handy built-in table.

Nothing says summer like a glass of lemonade, relaxing in the shade and hoping to catch a breezeor creating your own by giving your swing a kick. Of course, I always get so comfortable Im looking for a place to put my drink down and close my eyes. Now Ive got a swing designed to help. Integrated into the seat is a simple pop-up table that sits level to the ground while the swing keeps your back at a comfortable angle.

Start the project by heading to the lumber yard. The six-foot swing as shown required one 28, one 26, five 24s, and 10 14s all in eight-foot lengths. I chose western red cedar because its a durable, lightweight, outdoor wood and is less expensive than redwood. At Midwest prices, the lumber cost about $120.

Schedule of Materials: Garden Swing

| No. | Ltr. | Item | Dimensions (inches) | Material | Comments |

| T | W | L |

| 1 | A | Bottom back rail | 112 | 5 | 55 | Cedar |

| 2 | B | Back Stiles | 112 | 112 | 2078 | Cedar |

| 1 | C | Top Back rail | 112 | 8 | 60 | Cedar |

| 11 | D | Back Slats | 58 | 212 | 2012 | Cedar | Longest slat, cut to fit. |

| 2 | E | Seat rails | 112 | 3 | 60 | Cedar |

| 4 | F | Seat Stringers | 112 | 3 | 17 | Cedar |

| 21 | G | Seat Slats | 58 | 212 | 20 | Cedar |

| 2 | H | Arms | 114 | 3 | 2312 | Cedar |

| 2 | I | Arm Supports | 112 | 4 | 12 | Cedar |

| 2 | J | Table battens | 34 | 112 | 1978 | Cedar |

| 2 | K | Table legs | 1 | 114 | 612 | Cedar |

| 2 | L | Table legs | 1 | 114 | 13 | Cedar |

| 2 | M | Table leg braces | 58 | 114 | 13 | Cedar | Lenght oversize to allow fitting. |

| 2 | N | Table support cleats | 1 | 2 | 20 | Cedar |

SEAT FRAME

Once back in the shop, start construction by cutting the seat rails and stringers from the 24s. As you probably know, dimensional lumber comes with rounded edges. Youll need to get rid of them. Cut the pieces for the rails and stringers to their 3" thickness by first running one edge over the jointer until they have a square edge, then rip them to 3" wide. To give the seat a comfortable back angle, set your saw blade to a 7-degree bevel and run the back rail on edge to give a 7-degree angle to the back.

Now cut the pieces to length and screw the stringers between the rails, spacing them as shown. The center section spacing is critical because the pop-up table needs to be square so it can be lifted out and turned in place and the legs lowered. Use 2" galvanized deck screws when screwing the seat frame together.

Mill all the slats at the same time because they are essentially the same size. Cut the 14s into 24" lengths, and plane the boards to 58 thickness. Then rip them to their 212 width and crosscut the seat slats to 20". To give the swing a finished look, cut an 18 roundover on all four top edges of each seat slat using a bit mounted in a router table. Attach the slats for the permanent seats, running the slats from side to side. They should flush up in length to the outside edges of the stringers, and the front slat should be flush to the front rail. Use about 38 spacing between the slats. I decided to attach the slats to the frame using finish nails and an air nailer. This left a much smaller hole than screws, and it was very quick.

To finish the seat I decided to build the top surface of the table at this point. The spacing works the same as on the side seats, but run the slats from front to back. The slats are attached to two table battens (34 1 12 19 78) that are held 116 or so away from the inside face of the front and rear rails. This gap should allow the table to lift out without binding, but some slight fitting may be necessary. Dont worry about the legs yet, well do that later.

With the seat frame assembled, nailing the slats in place was a cinch with a pneumatic finish nailer and stainless steel nails. Note the 7-degree bevel on the rear of the back seat rail.