Copyright 2012 Helen S. Fletcher

All rights reserved.

ISBN: 1479127086

ISBN 13: 9781479127085

eBook ISBN: 978-1-62347-336-5

Helen S. Fletcher, St. Louis, Missouri

European Tarts, Divinely Doable Desserts with Little or No Baking

Dedication

For the two youngest loves of my life Sam and John for being Sam and John and bringing so much joy into my life.

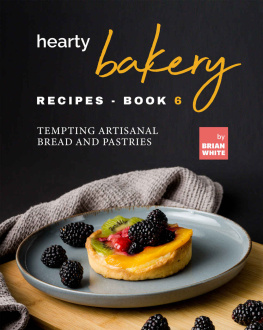

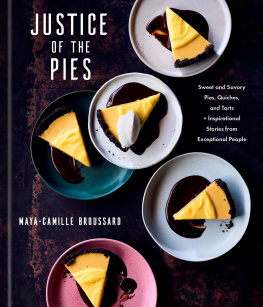

Top Left, Fresh Fruit Tart,

Top Right, Walnut Lace Tart,

Bottom Left, Triple Chocolate Tart,

Bottom Right, Chocolate Caramel Truffle, Tart,

European Tarts Table of Contents

When I first started my bakery, Truffes, Inc, some people warned that pastries made totally from scratch using all butter, 40% cream, the best of chocolate and nuts, with no box mixes, no bucket fillings and icings couldnt possibly make a profit. My belief that quality, consistency and service always sell kept me going in the lean, early years. However, it didnt happen all at once and we were, as many successful businesses, a ten-year overnight success.

From a background as a food writer, consultant and traveling teacher, I wanted to find a way to stay in town and do what I did best - bake. Having written articles that appeared in Bon Apptit, Chocolatier and The Pleasures of Cooking as well as authoring my first book, The New Pastry Cook, I gained some name recognition in St. Louis. With one client to start, I began Truffes, Inc., my upscale, handmade, wholesale pastry business. In the beginning, I started out of my house with a timetable of 6 months to see if I liked baking on a daily basis to the demands of clients instead of for myself, family and friends on an infrequent basis. I had promised my husband I would not turn our home into my place of business. As my clientele grew and I became known for unusual wedding cakes, it soon became clear that I would need to find a commissary from which to work. Because of the sheer cost of equipping a bakery, I set out to find a suitable spot which already had an established food service. This period was probably the most frustrating time in my business life. I looked everywhere and at anything that might work - even if I had to share it. I asked every one I knew, even remotely, if they knew of anywhere and finally a client told me about my location.

Although not equipped as a bakery, but set up for food, we quickly got rid of deep fat fryers and steam tables, and added ovens, refrigeration, a freezer and a 12 quart and 20 quart mixer in addition to my 5 quart mixer from home. When I was working out of my house, I stored all of my equipment in my sons former bedroom. After seeing the shelves of equipment one day, he exclaimed in dismay that I had turned his room into a warehouse. All of this equipment was moved into my 800 square foot commissary. I was on my way and I couldnt decide in the beginning whether I was excited and happy or just plain scared to death. It changed from minute to minute as I saw, in very short order, just how much I had to learn - and quickly!

In the beginning, everything was made to order. The client would call on a Monday or Tuesday and we would deliver on Thursday or Friday. With enough business to keep me busy 3 days a week doing the baking and finishing, pan washing and cleaning, it became evident that more clients were needed. So I added salesman to my growing list of newly developing talents. The first three years were such a steep learning curve, I almost fell off more than once. When I first started the business, I sold what I wanted to make. However, it didnt take long for me to listen to my clients to learn what they wanted. In the beginning I didnt make a carrot cake, not because they arent good, but my line was more European and I felt it didnt really fit in.

It took me a while to catch on and decide if I were going to make a carrot cake, as it appeared I had to, it would have to be the best one around. I learned, but sometimes it took me longer than it should have. However, my saving grace was I started learning faster and faster as the company grew at a rapid pace.

I soon hired my first dishwasher for 3 days a week and thought I was living mighty high.

I continued to add part time help to make Press-In crusts for the tarts, chop chocolate, squeeze lemons and do some of the other more time consuming chores. Soon, full time help was needed, more space was required, and the line was turned from made to order to frozen, in order to keep up with our competition. The product line was culled and anything that did not thaw and retain its quality was eliminated. I did regular assessments of my competition and it became apparent we could not sustain growth as a made to order business. Especially, since it became obvious that our main competition was large distributors that brought in frozen desserts from out of town. In addition to a much more stable product with a longer shelf life, the distributors could offer next day delivery, which I couldnt. To solve that problem we took over the adjacent 800 square foot bay, broke through the wall and added, what we thought at the time to be a monstrous combination refrigerator/freezer. The plan worked better than expected and within a few months we were crowding our freezer something fierce. Fifteen months later we took another bay, opened another door, added another freezer, a cutting machine and a packaging machine to ease our labor problems as well as equipped the bakery with more ovens, and larger mixers. With 2400 square feet and approximately 100 clients, our biggest problem was to wean our wonderful clients away from their favorites and let us add new items. They always wanted the new but hated to give up anything old. With about 100 items offered, it was difficult sometimes to keep up. But quality and consistency whether in product or service remained our guide and we went to great lengths to be of help.

The most important thing I have learned is that anyone, with or without specialized training, (I have had no training) but a keen interest in a subject, can master that subject if they just remember to enjoy it as they go. Almost all of my employees, had little to no baking experience, but they learned to produce all the items in this book and a great deal more. To say I have not experienced great frustration would be to misrepresent reality. However, learning to work with people, being able to help my clients, learning so much of the nitty-gritty of running a successful business has given me more pleasure than I fear I have returned. And even on my worse day, I still loved it!

In the

Beginning

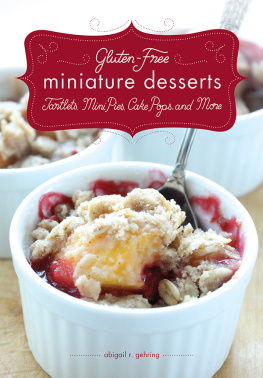

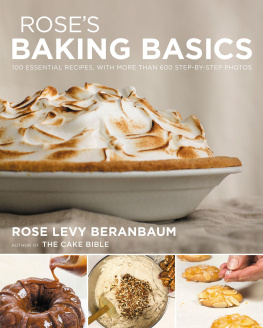

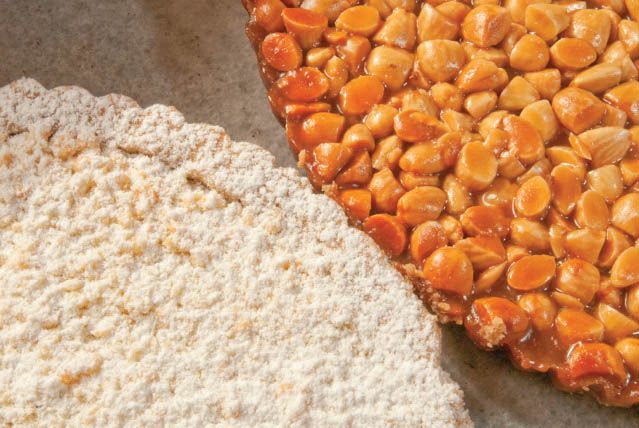

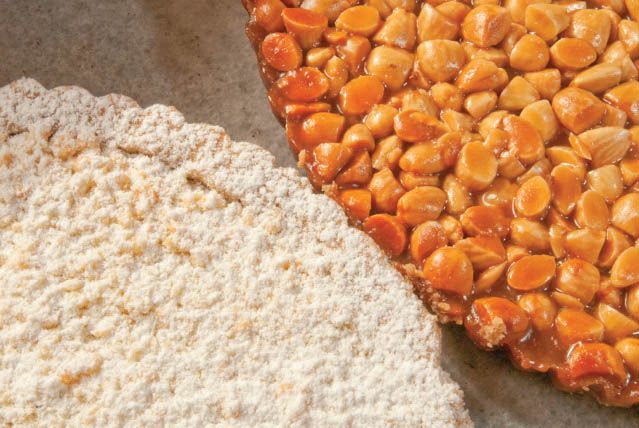

Left, Rum Raisin Tart,

Right, Honey Almond Tart,

European Tarts Introduction

The uniqueness of this book lies in the fact that all of these tarts were made in my bakery, Truffes, Inc. in St. Louis, Missouri for more than 23 years and sold wholesale to restaurants, caterers and hotels. Although they were produced in quantity at the bakery, each recipe and their component parts have been tested and re-tested for a single recipe made in a home kitchen for this book. There are many factors that are different when baking for production and baking at home. Key among them are ovens used, various mixer sizes (we had five different sized mixers that could accommodate bowls from 5 quarts to 80 quarts) as well as ingredients not available to consumers. While this book uses seedless red raspberry jam, at the bakery we used a product called European Raspberry Filling from Henry and Henry. It was bake proof, meaning it would not turn liquid when baked and it had more body for piping, making it much easier to use than jam, which loses its body when whisked for piping. However, I have fortified the jam used in this book so it works fine and there is no difference in taste. Emulsified powdered sugar is another example. We could sprinkle items with emulsified powdered sugar and it would not liquefy in the refrigerator or on thawing as will normal powdered sugar. At home, sprinkling with powdered sugar when ready to serve solves this problem.

Next page