"

DEMING'S MANAGEMENT PHILOSOPHIES ARE THE DRIVING FORCE BEHIND JAPAN'S ECONOMIC MIRACLE."- USA TODAY

T he A m erican W ho T aught t he J apanese A bout Q uality

THE MANAGEMENT PHILOSOPHY THAT TRANSFORMED JAPAN AND IS CHANGING THE WAY SUCCESSFUL COMPANIES DO BUSINESS

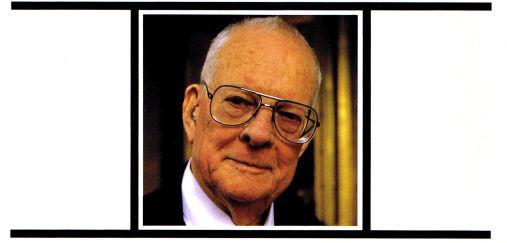

Dr. Deming

Dr. Deming

The American Who Taught

the Japanese About Quality

Rafael Aguayo

A Millennia Management Book

Published by Rafael Aguayo

First Carol Publishing Edition 1990 Copyright 1990, 2010 by Rafael Aguayo

A Millennia Management Book

Published by Rafael Aguayo

All rights reserved

including the right of reproduction

in whole or in part in any form.

Queries regarding rights and permissions should be addressed:

Rafael Aguayo, 15 Friends Rd, Setauket, New York, NY 11733

10 9 8 7 6 5 4 3 2 1

Figures on page 120 and 161 reprinted from Out of the Crisis by W. Edwards Deming, by permission of MIT and W. Edwards Deming. Published by MIT, Center for Advanced Engineering Study, Cambridge, Mass. 02139. Copyright 1982, 1986 by W. Edwards Deming. Figure on page 164 reprinted from Guide to Quality Control by Dr. Kaoru Ishikawa, by permission of the publisher, the Asian Productivity Organization

Library of Congress Cataloging-in-Publication Data

Aguayo, Rafael.

Dr. Deming the man who taught the Japanese about quality / by Rafael Aguayo.

p. cm.

"A Lyle Stuart book."

ISBN 0-8184-0519-8:

1. Quality controlUnited States. 2. Deming, W. Edwards (William Edwards), 1990 1993 I. Title.

TS156.A35 1990

658.5'62'092dc2O

90-47036

CIP

To ALL MY TEACHERS, ESPECIALLY

Aida R. Aguayo

J. Roberto Aguayo

Lincoln Barnett

Eido T'ai Shimano

Kyudo Nakagawa

W Edwards Deming

To MY FAMILY,

Alexis, Brendan, Cindia, Peggy, and Hops

Preface to the Digital Edition of Dr. Deming:The American who Taught the Japanese about Quality

A Twenty Year Perspective

This year marks the twentieth anniversary of the publication of Dr. Deming: The American who Taught the Japanese About Quality. In reviewing and proofreading the book for this digital version I was struck with how well the basic message of the book has survived.

Even during those first encounters with Deming it was clear that understanding management principles was critical. Any initiative that stressed quality or process improvement was doomed to backfire unless those involved had a deep understanding of the principles of quality management. Organizations that began initiatives in cost reduction or profit improvement blindly, as is often the case, would likely experience disaster.

Twenty Years of Corporate Experience

The past twenty years have given us examples of companies who understood this and experienced dramatic, sustainable improvements as a result. When I attended, at Deming's invitation, one of his 4-day seminars in the 1980s, Intel and Proctor & Gamble were two major attendees. Both prospered, grew dramatically, showed leadership and rewarded their shareholders. Another established company Colgate Palmolive under its chairman Reuben Mark carefully and systematically adopted quality principles at the same time and also experienced spectacular results that have continued to this day. A glance at the long term charts of the stocks of these companies gives a good proxy for their long term performance.

An example of an on again off again commitment to good management and quality principles can be found in Ford Motor Company. As documented in the text Ford experienced a dramatic turnaround in its fortunes beginning in 1980. Under Deming's guidance Donald Petersen made Quality Job One at Ford. The result was a hugely successful, innovative, customer focused company that was fair to employees and rewarded shareholders. Profits and sales followed an upward trajectory. But Petersen was pushed out of Ford in 1990 and executives with a traditional managerial mindset took over the company and pushed it back to the brink. In the early years of the new century Ford experienced yearly losses that were as highs as $12 billion.

Facing the abyss, the company solicited a new CEO from outside the industry who had demonstrated success in turning around the main division of Boeing using principles based on the Toyota Production System. I am not prepared to predict the long term health of Ford, but so far there are some positive developments including a greater emphasis on the quality of its products. The new CEO actually drove many of Ford's cars himself early on in his new job. Ford's cars are now receiving much higher quality marks from consumers and several influential magazines. This bodes well for its future.

My Personal Experience

After the book was published in 1990 I began receiving calls to lecture and consult. My main focus was to further develop my own understanding and effectiveness. Prior to writing the book I had used Deming management principles in my own business and in coaching my son's little league soccer team with dramatic results. Those results convinced me of the power of quality management principles and enhanced my confidence and my ability to persuasively explain them to others. But just how powerful were these principles? Could they effectively turn around a failing or mediocre operation? If so how long would it take? What else would a person need to be an effective agent of change?

I became much more accomplished in process improvement tools and that was helpful. But convincing people in an organization that putting quality and customers first was the right path can be a challenge. Not having alignment among people in an organization is a serious limiting constraint that puts a brake on improvement. So I assiduously studied psychology, hypnosis and related subjects; and vigorously pursued training on people skills. As my process tools and people skills improved I pushed the envelope further and further. I looked to work on extreme turnarounds. My last consulting assignment involved a company that had no right to be alive. It had a large negative net worth, was losing tons of money every month, its business was shrinking, the industry was dying, and the country was entering a recession. All its assets were assigned to an asset based lender who wanted out. Its managers were scared and depressed. They didn't have a clue as to how to proceed. Yet, in two years we turned the company around and it experienced its most profitable quarter in its over 100 year history.

While process tools and people skills played a key role in that turnaround, the experience confirmed that the original message of the book was not only the right one but the most critically important part of the puzzle. I subsequently began teaching at a major university. I was a little insecure at first in this new role and began to emphasize techniques to students. But they showed me that unless the management principles were understood techniques were useless. Once the philosophy and rationale is understood on a basic level the tools can become powerful aids to achieving results and also serve to reinforce the principlesas long as they had been properly taught.

DEMING'S MANAGEMENT PHILOSOPHIES ARE THE DRIVING FORCE BEHIND JAPAN'S ECONOMIC MIRACLE."- USA TODAY

DEMING'S MANAGEMENT PHILOSOPHIES ARE THE DRIVING FORCE BEHIND JAPAN'S ECONOMIC MIRACLE."- USA TODAY