Contents

Page List

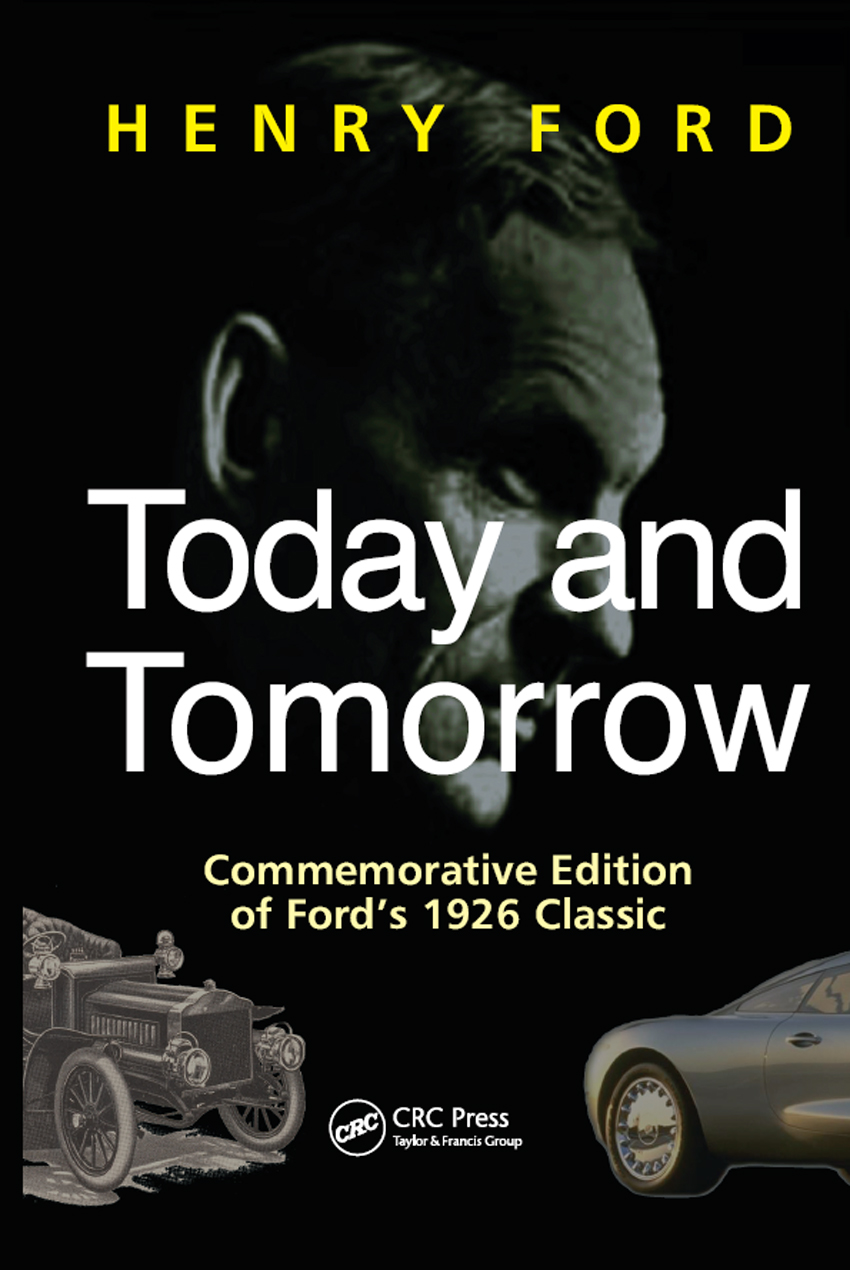

Today and Tomorrow

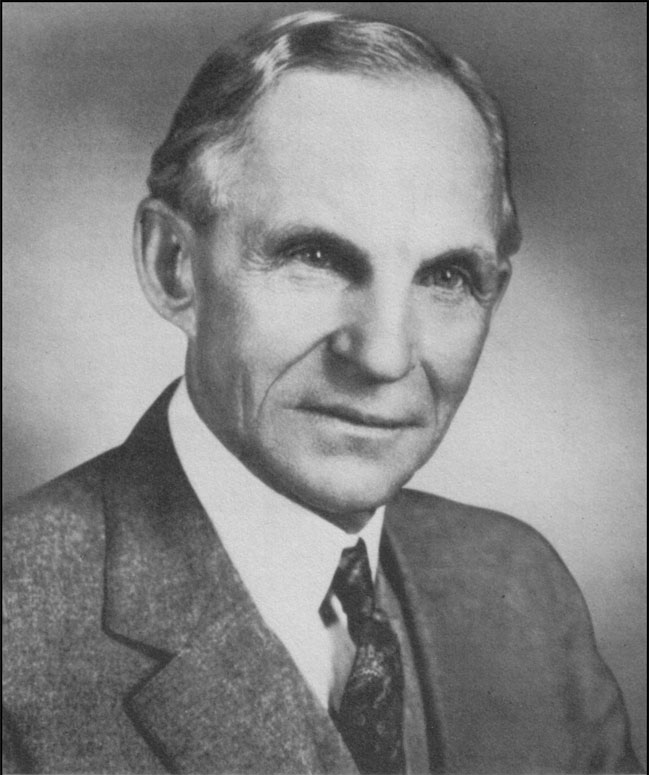

Henry Ford

(1863-1943)

Today and Tomorrow

By Henry Ford

(in collaboration with Samuel Crowther)

CRC Press

Taylor & Francis Group

6000 Broken Sound Parkway NW, Suite 300

Boca Raton, FL 33487-2742

Reprint edition 1988 and updated printing 2003 by Taylor & Francis Group, LLC

CRC Press is an imprint of Taylor & Francis Group, an Informa business

A Productivity Press Book

No claim to original U.S. Government works

Printed in the United States of America on acid-free paper

10 9

International Standard Book Number-13: 978-0-915299-36-4 (Hardcover)

Library of Congress Card Number 88-42628

This reprint edition is published by arrangement with Doubleday, a division of Bantam Doubleday, Dell Publishing Group, Inc. 1926 by Doubleday, Page & Company

CRC Press gratefully acknowledges the cooperation and assistance of Ford Motor Company in providing Henry Ford biographical material, and the Henry Ford Archives, Henry Ford Museum and Greenfield Village Collections in providing photographs.

This book contains information obtained from authentic and highly regarded sources. Reprinted material is quoted with permission, and sources are indicated. A wide variety of references are listed. Reasonable efforts have been made to publish reliable data and information, but the author and the publisher cannot assume responsibility for the validity of all materials or for the consequences of their use.

Except as permitted under U.S. Copyright Law, no part of this book may be reprinted, reproduced, transmitted, or utilized in any form by any electronic, mechanical, or other means, now known or hereafter invented, including photocopying, microfilming, and recording, or in any information storage or retrieval system, without written permission from the publishers.

Trademark Notice: Product or corporate names may be trademarks or registered trademarks, and are used only for identification and explanation without intent to infringe.

Library of Congress Cataloging-in-Publication Data

Ford, Henry, 1863-1947

Today and tomorrow / by Henry Ford in collaboration with Samuel Crowther; foreword by Norman Bodek. Reprint. Originally published: Garden City, NY: Doubleday, Page & Company 1926.

p. cm.

ISBN 0-915299-36-4

1. Ford Motor Company. 2. Industrial management. I. Crowther, Samuel, 1880-1947. II. Title.

HD9710.U54F5831988

658.4dc19

88-42628

Visit the Taylor & Francis Web site at

http://www.taylorandfrancis.com

and the CRC Press Web site at

http://www.crcpress.com

or http://www.productivitypress.com

Table of Contents

I n 1988, Productivity Press first reprinted Henry Fords Today and Tomorrow, on the occasion of Ford Motor Companys 85th anniversary. Fifteen years later, we continue to publish this bookand with good reason. For those interested in advancing industry and manufacturing, there is simply no substitute for reading Fords ideas firsthand. Time and again, the roots of lean manufacturing have been traced to Henry Fords thinking about production systems. But learning this second-hand does not carry the same impact as delving into Fords thinking and his experience by reading his own words.

Today, as the prospects for the five-day car make business headlines, we cannot help but look back in awe at Fords achievement of an average production cycle of not more than five days from the mine to the finished machine in the freight car. Of course, in 1926, circumstances were differenta different stage in the evolution of industry and society, a different labor force, different market conditions, different technology. Beyond the specifics of any of Fords individual achievements or practices (as remarkable as so many of them are even now) is the reach of his ideas about industry and manufacturing. Acknowledging that any particular methodology or solution is bound to become obsolete, he says:

Our own attitude is that we are charged with discovering the best way of doing everything, and that we must regard every process employed in manufacturing as purely experimental. If we reach a stage in production which seems remarkable as compared with what has gone before, then that is just a stage of production and nothing more. We know from the changes that have already been brought about that far greater changes are to come. Our invariable reply to It cant be done is, Go do it.

Fords expression of these timeless principles continues to make for fascinating reading a century after the founding of his company.

In honor of Ford Motor Companys 100th anniversary, we offer this updated printing of Productivity Presss edition, featuring a new introduction by James J. Padilla, group vice president of Ford North America. In addition, we include a new selection of photographs to better illustrate some of the many operations Henry Ford describes in the text.

We are grateful to all those who assisted in this endeavor, especially to Peter Tassi at Fords Total Cost Management Center, Barbara Teasdale at Fords Centennial Operations office, Michelle Graham at the Ford Motor Company Archives and Laura Mancini at the Benson Ford Research Center, Henry Ford Museum & Greenfield Village.

Maura May

Publisher

I WAS FIRST introduced to the concepts of just-in-time (JIT) and the Toyota production system in 1980. Subsequently I had the opportunity to witness its actual application at Toyota on one of our numerous Japanese study missions. There I met Mr. Taiichi Ohno, the systems creator. When bombarded with questions from our group on what inspired his thinking, he just laughed and said he learned it all from Henry Fords book.

While it took me a few years to find a copy of the out-of-print book, sure enough, on the first reading I discovered that many of the ideas we call just-in-time came from the way Henry Ford organized his production process. In 1926 it took his workers only 81 hours to go from iron ore to finished product. Imagine it taking only three days and nine hours to produce an automobile.

Going back and reading his words, I saw not only the fundamentals of JIT but also a wide scope of wonderful ideas that he used to make his company the most successful in the world. Henry Ford talked about zero defect production and eliminating the need for quality checks at the end of the production process. He believed strongly in allowing the workers to benefit from what they were actually producing. He reduced the price of a car in half and doubled worker wages from $2.50 to $5.00 a day.

Its incredible to think of doubling peoples wages and simultaneously reducing the price of your product. But Mr. Ford believed that workers under his manufacturing system would improve productivity beyond all past expectations and thereby lower costs to consumers. His dream was to improve society by making automobiles available to anyone who wanted one.

He insisted that work environments be spotlessly clean; that business leaders think in terms of serving their communities and the society at large; that production techniques not be taken for granted but continuously change and improve. He said that primary industries should help their suppliers and the service industries to produce cheaper and better products in less time; and that managers should not remain in their offices but should walk around, know their workers, and be capable of doing the work them-selves. He emphasized that workers should be trained and have the opportunity to better themselves and make product improvements.