Table of Contents

List of tables

- Tables in Chapter 1

- Tables in Chapter 2

- Tables in Chapter 3

- Tables in Chapter 4

- Tables in Chapter 5

List of illustrations

- Figures in Chapter 1

- Figures in Chapter 2

- Figures in Chapter 3

- Figures in Chapter 4

- Figures in Chapter 5

Landmarks

Table of Contents

A Systems Approach to Managing the Complexities of Process Industries

Fabienne Salimi

Process Safety Expert, ADEPP Academy

Frederic Salimi

Process Safety Expert, ADEPP Academy

Copyright

Elsevier

Radarweg 29, PO Box 211, 1000 AE Amsterdam, Netherlands

The Boulevard, Langford Lane, Kidlington, Oxford OX5 1GB, United Kingdom

50 Hampshire Street, 5th Floor, Cambridge, MA 02139, United States

Copyright 2018 Elsevier Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publishers permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library

Library of Congress Cataloging-in-Publication Data

A catalog record for this book is available from the Library of Congress

ISBN: 978-0-12-804213-7

For Information on all Elsevier publications visit our website at https://www.elsevier.com/books-and-journals

Publisher: Joe Hayton

Acquisition Editor: Kostas Marinakis

Editorial Project Manager: Jennifer Pierce

Production Project Manager: Sruthi Satheesh

Designer: Mark Rogers

Typeset by MPS Limited, Chennai, India

Acknowledgments

I was always amazed about the wonders that man-kind can do when they join their forces to turn a dream to a reality. When I was a child, I was thinking What if the brains of all people on the world are interconnected to make a huge brain? My friends and mentors smiled and did not take this question seriously.

Today, technology gives us the required tools to think more seriously about this question. The IIoT and augmented reality are already there and stimulate imagination of many of us.

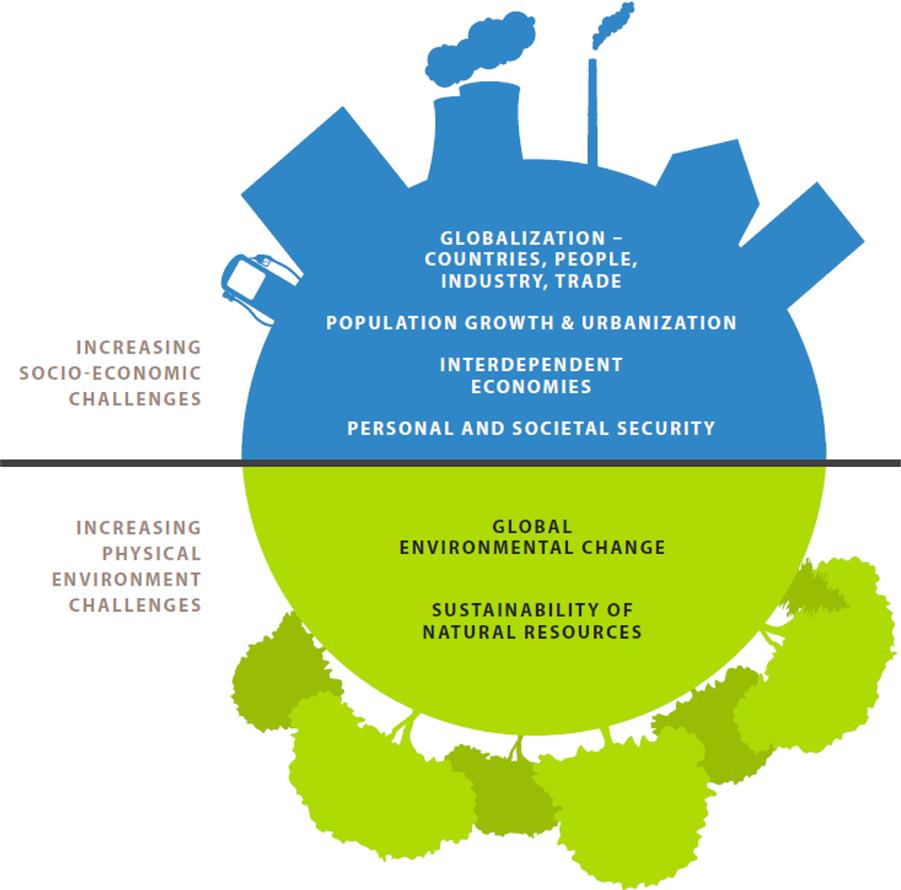

As the health, safety, and environmental practitioners, we understand that the complex solutions engineered to meet fundamental human needs. They should be safe and not harm people and environment. But what does complexity mean in process industry and how can we manage it?

INCOSE Vision 2025 - Page 7.

Since 1994, the authors of this book have reflected on this question and developed a tool called ADEPP (Analysis & Dynamic Evaluation of Project Processes). We acknowledge the importance of technical and financial supports of the French innovation organizations in particular Institute Franais du Ptrole (IFP) in development of version 1 of ADEPP.

In 2014 the authors created a partnership with the following companies to develop the prototype of version 2 of ADEPP. We acknowledge their trust and importance in crystallization of the ideas that we express in this book:

Hydraulic Analysis Ltd+Software Simulation Ltd (United Kingdom)

VMG (Europe Branch in Spain)

Antea (Italy)

Human Focus (United Kingdom)

EON Reality (France)

We also acknowledge the positive reception and constructive discussions with the following system engineering and complexity experts who inspired and encouraged us:

Alan Hayman (System and Complexity Thinking Consultant)

Frank Verschueren (Engineer Inspector for FOD WASO/Belgian fed government COMAH regulations)

Matthew E. Weilert (Systems Thinking & Engineering Consultant)

Gene Bellinger (Systems Thinking & Engineering visionary)

Joss Colchester (director and developer of complexity academy, i.e.an excellent source of high-quality system and complexity courses for the beginners)

Mark Simpson (Product Manager at Siemens)

We acknowledge the usage of the valuable books and documents published by the following organizations for promotion of system engineering, system thinking, complexity thinking, quality and risk thinking, and IIoT:

INCOSE (International Council on Systems Engineering)

SEBoK (Systems Engineering Body of Knowledge)

LNS Research

SkybraryAviation Safety

NASA (National Aeronautics and Space Administration)

MIMSOA (Maintenance Information Management Open System Alliance)

Health & Safety Executive (United Kingdom)

Energy Institute

IOGP (International Oil & Gas Producers)

Finally, we express our gratitude towards all those individuals and companies who directly or indirectly contributed in our education and professional understanding. May this book pay a humble tribute to their efforts.

Fabienne-Fariba Salimi and Frederic Salimi

Chapter 1

Perspective

Abstract

This chapter discusses the issues related to effective implementation of the process safety management system (PSM) as a part of the operational excellence. Risk based approach of PSM calls for addressing the potential technical, human, and organizational failures simultaneously. Bow-tie method is used to demonstrate the complexity associated to the PSM elements. Then the practical methods to assess and manage the complexity are discussed. The approaches of the manufacturing and process industries to assess and manage the complexity are compared. Application of ISA-95, API 754, System Engineering Standard ISO/IEC 15288, and IIoT for operational excellence and management of the risk of major accidents in process industry are discussed. The chapter also discusses the distinction between process and procedure and the several technical processes that are involved (e.g., integration process, transition process, validation process, etc.).