IATF 16949:2016

Audit Guide and Checklist

Version 2.0

Copyright 2018

SystemsThinking.Works

Second Edition

January 2018

This publication is protected by Copyright Law, with all rights reserved. No part of this publication may be stored in a retrieval system, transmitted or reproduced in any way, including but not limited to photocopy, photograph, magnetic or other record, without the prior agreement and written permission of the author at SystemsThinking.Works.

Visit

SystemsThinking.Works

Table of Contents

A PROCESS BASED CHECKLIST

858 QUESTIONS

584 Questions Covering

ISO 9001: 2015, IATF 16949:2016Requirements

+

188 Questions Covering

The 2017Customer Specific Requirements for

GM (26), Ford (47),FCA (35),

Volkswagen (53), PSA Group* (27)

*Added in the 2 Addition

+

71 Questions Covering

Automotive Core Tools Requirements

APQP -Control Plan/FMEA Handbook (2017)

MSA/Process Capability/PPAP

+

15 Questions Covering

CQI Requirements

+

24 Pages of Additional Resource Information 6 Pages of Reference Material and Approximately 150 Notes to assist auditors

NEW in the 2nd Edition

1. Added Guidance for effective implementation of Context of the Organization

2. Revised and expanded explanation of Clause 5.1.1c. - Integration of QMS

3. Additional detail for MAQMSR requirements

4. Updates based upon IATF responses to FAQs as of Nov 1, 2017

5. Updates based upon IATF 2017 Sanctioned Interpretation

6. Updates and additions to the latest 2017 OEM Customer Specific Requirements

7. Added questions covering the latest 2017 FMEA Handbook (33 questions)

8. 15 Additional questions to emphasize control of Safety Related Products and Characteristics

Foreword

The creation of this 2nd Edition guidebook and checklist brings this guide to the most up to date list of requirements that we can offer. This book is a checklist, but it is a unique checklist. It is not just a list of questions which elicit a specific correct answer. The questions here are intended to help auditors find evidence of an effective and efficient system. The questions follow a Plan, Do, Check, Act Process Approach to finding evidence. Auditors are expected to gather evidence, review it, evaluate it and then determine for themselves the effectiveness of the system being audited and whether the requirements are fully met. Many of the questions require observation. Others require review of documents or records. Other questions ask the auditor to make a value judgment, (Is evidence sufficient?). In this way, auditors will have guidelines which, combined with their own knowledge and skills, will create a complete and value adding audit.

This book could not have been written without help. I owe a great deal of thanks to many people whose questions and discussions have shaped my approach and content of this book. To all of my audit students, fellow registration auditors, colleagues and friends who have helped me, mostly unknowingly, to develop, revise and constantly expand my thinking with regard to Quality Management Systems, Auditing and management in general, Thank You!

And finally, I would like to thank you, the purchaser and user of this book. I sincerely hope, this book will provide you and your organization with the information that you need to achieve your goals and objectives.

Sincerely,

Pat Ambrose

INTRODUCTION

There is one important consideration that the management of your organization should make before choosing to use the checklists included in this Guide. They must carefully consider their objectives regarding your IATF 16949 / ISO 9001 Quality Management System. If what they are looking for is the easiest way to get and keep their IATF registration, or if their aim is to take the paperclip and bubble gum approach i.e. identify the exact wording changes and modify the documentation, THIS IS PROBABLY NOT THE BOOK FOR YOU. Neither is this book and the checklists in it simply a regurgitation of IATF Customer expectations. The questions included in this checklist are designed to promote best practices. This checklist is for organizations with a desire to get their moneys worth and more out of their systems. The questions strive to provide a value-added, effective and efficient quality management system that will provide customers with conforming products, effective supplier systems performance and effective supplier/customer relations while providing your organization with an efficient and cost-effective system.

This book does not promote bureaucracy or endless procedures. The questions and notes provided are intended to assess whether your system is first and foremost Effective.

Certainly, you have the option and I would expect that you will skip or delete questions that are of no value to your organization. I would also expect that you will modify questions or even add additional questions of your own. I welcome your participation in this effort to get the maximum value from this resource.

Pat Ambrose

1. CHECKLIST SUMMARY

2. AN INTRODUCTION TO IATF 16949:2016

With this new International Standard, some of the structure and terminology in TS 16949: 2009 and ISO 9001:2008 has been changed to improve alignment with other management systems standards. Basic Changes include:

TS (Technical Specification) is now IATF (International Automotive Task Force)

The combined format has become two distinct but linked documents (See FAQ answer below)

The adoption of the HLS (standardized High Level Structure) (ISO and IATF)

An explicit requirement for risk-based thinking (ISO and IATF)

Reinforced application of the process approach (ISO and IATF)

Fewer prescribed requirements (ISO)

More detailed and better defined requirements (IATF)

Less emphasis on documents (ISO)

Clearer document requirements (IATF)

Inclusion of customer specifics into some requirements (IATF)

A requirement to define the boundaries of the QMS (ISO and IATF)

Emphasis on organizational context (ISO and IATF)

Emphasis on the needs and expectations of interested parties (ISO and IATF)

Increased leadership requirements (Active Participation) (ISO and IATF)

Greater emphasis on the achievement of desired outcomes to improve customer satisfaction (Performance Measurement) (ISO and IATF)

IATF FAQ - Why are there two manuals (IATF 16949:2016 and ISO 9001:2015)?

ANSWER - The IATF and ISO were not able to reach a licensing agreement to publish IATF 16949 with the ISO 9001 in an integrated document.

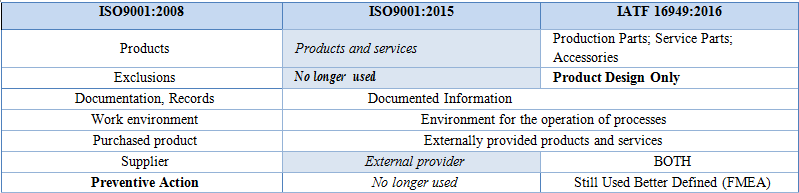

Major Differences in Terminology between Previous and New Standards:

Additional IATF CHANGES

Scope: The new scope includes accessory parts made for the OEMs and stresses customer requirements and product with embedded software.