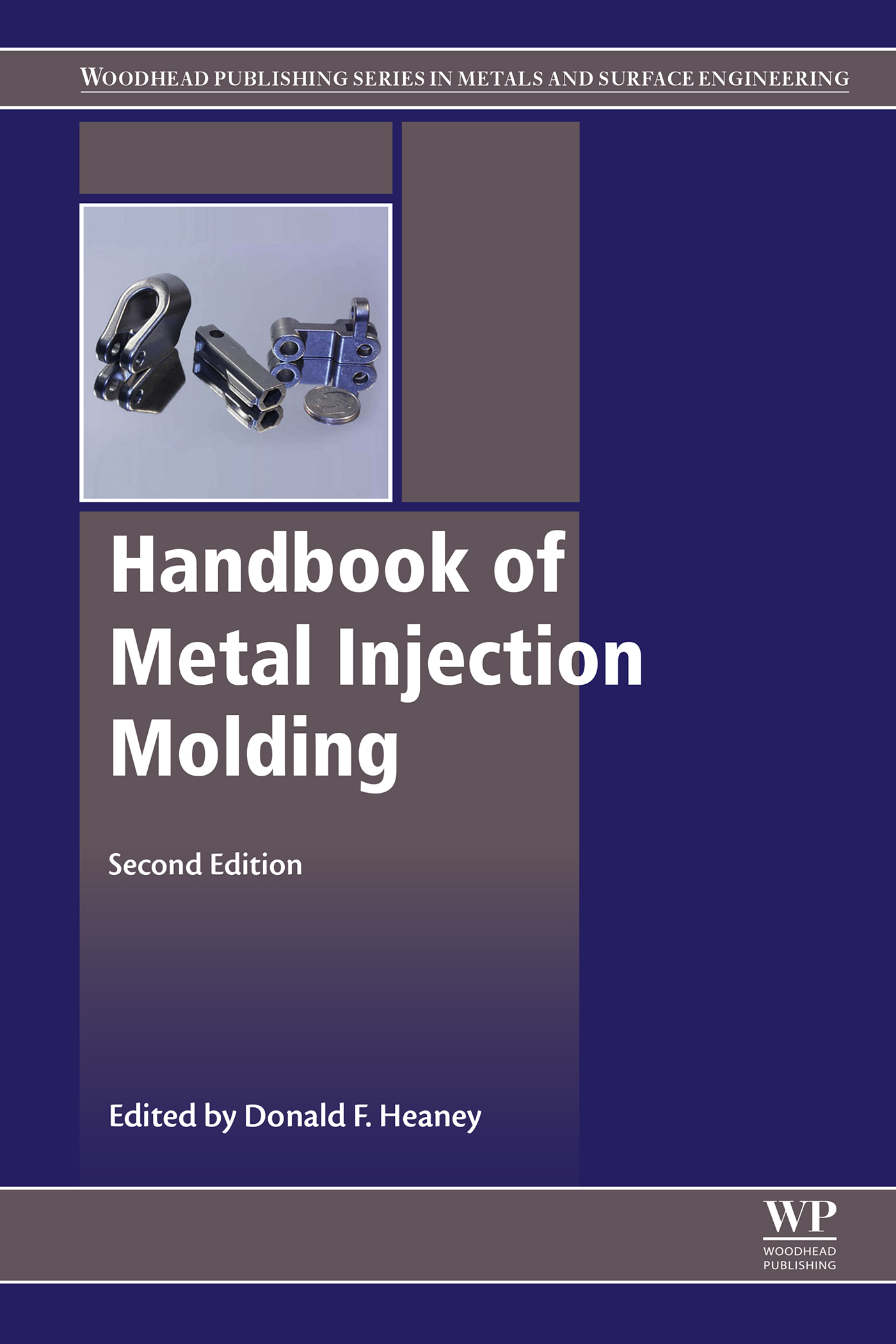

Woodhead Publishing. - Handbook of Metal Injection Molding

Here you can read online Woodhead Publishing. - Handbook of Metal Injection Molding full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. City: Cambridge;Duxford;Kidlington, year: 2019, publisher: Elsevier Ltd.;Woodhead Publishing, genre: Romance novel. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Handbook of Metal Injection Molding

- Author:

- Publisher:Elsevier Ltd.;Woodhead Publishing

- Genre:

- Year:2019

- City:Cambridge;Duxford;Kidlington

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

Handbook of Metal Injection Molding: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Handbook of Metal Injection Molding" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Handbook of Metal Injection Molding — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Handbook of Metal Injection Molding" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

Second Edition

Donald F. Heaney

Woodhead Publishing is an imprint of Elsevier

The Officers Mess Business Centre, Royston Road, Duxford, CB22 4QH, United Kingdom

50 Hampshire Street, 5th Floor, Cambridge, MA 02139, United States

The Boulevard, Langford Lane, Kidlington, OX5 1GB, United Kingdom

Copyright 2019 Elsevier Ltd. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publisher's permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

Library of Congress Cataloging-in-Publication Data

A catalog record for this book is available from the Library of Congress

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library

ISBN: 978-0-08-102152-1 (print)

ISBN: 978-0-08-102809-4 (online)

For information on all Woodhead publications visit our website at https://www.elsevier.com/books-and-journals

Publisher: Matthew Deans

Acquisition Editor: Christina Gifford

Editorial Project Manager: Lindsay Lawrence

Production Project Manager: Joy Christel Neumarin Honest Thangiah

Cover Designer: Victoria Pearson

Typeset by SPi Global, India

S. Ahn Pusan National University, Busan, South Korea

S.V. Atre University of Louisville, Louisville, KY, United States

S. Banerjee

DSH Technologies LLC, Cedar Grove, NJ

Holo Inc., Oakland, CA, United States

C. Binet Advanced Powder Products, Inc., Philipsburg, PA, United States

S.H. Chung Hyundai Steel Co., Incheon, South Korea

S.T. Chung CetaTech Inc., Sacheon, South Korea

T. Ebel Helmholtz-Zentrum Geesthacht, Geesthacht, Germany

R.K. Enneti Global Tungsten and Powders, Towanda, PA, United States

R.M. German San Diego State University, San Diego, CA, United States

C.D. Greene Treemen Industries, Inc., Boardman, OH, United States

O. Gulsoy Marmara University, Istanbul, Turkey

D.F. Heaney Advanced Powder Products, Inc., Philipsburg, PA, United States

Gemma Herranz University of Castilla La Mancha, INEI-ETSII, Ciudad Real, Spain

J. Hidalgo Delft University of Technology, Delft, The Netherlands

K. Horke Joint Institute of Advanced Materials and Processes, Friedrich-Alexander Universitt Erlangen-Nrnberg, Germany

K.S. Hwang National Taiwan University, Taipei, Taiwan, ROC

C.J. Joens Elnik Systems LLC, Cedar Grove, NJ, United States

J.L. Johnson Elmet Technologies LLC, Lewiston, ME, United States

T.G. Kang Korea Aerospace University, Goyang, South Korea

K.H. Kate University of Louisville, Louisville, KY, United States

Y.S. Kwon CetaTech Inc., Sacheon, South Korea

H. Lobo DatapointLabs, Ithaca, NY, United States

M. Martens Formatec Ceramics, DV Goirle, The Netherlands

A. Meyer Joint Institute of Advanced Materials and Processes, Friedrich-Alexander Universitt Erlangen-Nrnberg, Germany

H. Miura Kyushu University, Fukuoka, Japan

N.S. Myers Kennametal, Inc., Pittsburgh, PA, United States

K. Nishiyabu Kindai University, Higashisaka, Japan

V.P. Onbattuvelli Intel Corporation, Santa Clara, CA, United States

S.J. Park POSTECH, Pohang, South Korea

V. Piotter Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany

G. Schlieper Gammatec Engineering GmbH, Radevormwald, Germany

R.F. Singer Neue Materialien Frth GmbH, Germany

J.T. Strauss HJE Company, Inc., Queensbury, NY, United States

P. Suri Heraeus Materials Technology LLC, Singapore, Singapore

J.M. Torralba Institute IMDEA Materials, Universidad Carlos III de Madrid, Madrid, Spain

P. Vervoort Eisenmann Thermal Solutions, Bovenden, Germany

R.M. German San Diego State University, San Diego, CA, United States

Metal powder injection molding (MIM) has been in production since the 1970s. During that time, the market has expanded enormously to include a broad array of applications; the initial successes were in dental orthodontic brackets, watch cases, and firearms, but recently the technology has moved into higher performance, life-critical applications in dental implants, artificial joints, heart pacemakers, and aerospace jet engines. This chapter provides a statistical overview of MIM, its applications, growth, financial performance, and growth prospects.

Markets; Productivity; Sales; Applications; Production statistics; Capacity; Financial

Powder injection molding (PIM) has a main subdivision, metal powder injection molding (MIM), that has penetrated many fields. This chapter captures the status of the MIM field and provides a basis for evaluating different operations, markets, and regions. Like powder metallurgy, MIM relies on shaping metal particles and subsequently sintering those particles. The final product is nearly full density, unlike press-sinter powder metallurgy. Hence, MIM products are competitive with most other metal component fabrication routes, and especially are successful in delivering higher strength compared with die casting, improved tolerances compared with investment or sand casting, and more shape complexity compared with most other forming routes. Injection molding enables shape complexity, high-production quantities, excellent performance, and often is lower in cost with respect to the competition. Its origin traces to first demonstrations in the 1930s. In the metallic variant, most of the growth has been after 1990, when profitable operations began to emerge following several years of incubation.

Font size:

Interval:

Bookmark:

Similar books «Handbook of Metal Injection Molding»

Look at similar books to Handbook of Metal Injection Molding. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Handbook of Metal Injection Molding and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.