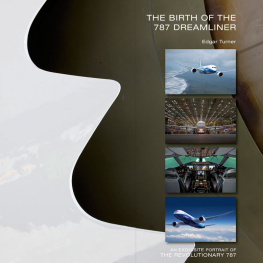

Concept and design copyright 2010 PQ Blackwell Limited Text copyright 2010 The Boeing Company

Images copyright 2010 The Boeing Company, by Edgar Turner except: Daniel Thompson,

Hardcover edition published in 2010 by

Andrews McMeel Publishing, LLC,

an Andrews McMeel Universal company,

1130 Walnut Street, Kansas City, Missouri 64106

www.andrewsmcmeel.com

ISBN: 978-1-4494-4208-8

Library of Congress Control Number: 2010927044

Produced and originated by PQ Blackwell Limited,

116 Symonds Street, Auckland, New Zealand

www.pqblackwell.com

787 DREAMLINER, 787 Dreamliner Livery, BOEING, Boeing Corporate Logo are trademarks of The Boeing Company. All worldwide rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval systems without permission in writing from the publisher.

Concept book design by Cameron Gibb

Additional design by Sarah Anderson

CONTENTS

A Global Supply Chain

How do you go about making a radical new airplane? Boeing did it by finding the people who could help invent the technology and apply the expertise to create something revolutionary. For the 787 Dreamliner, the collaborations sprung from all corners of the world.

According to Robert Noble, vice president of Boeing Supplier Management, 787 program, This airplane is different. Its all different. And that affects everybody. Design engineers, manufacturing engineers, every mechanic on the floor, and how we transport all the components.

Whether a part comes from Boeing or from a partner, each one must be produced exactly as designed. Each one is proven and tested by both Boeing and the supplier. Then each will meet up with millions of other parts at final assembly and become part of a new 787 airplane.

The Boeing Fabrication Division builds parts, assemblies, and toolingstructures used to build the airplaneat sites in the United States, Canada, and Australia. Parts from outside of Boeing are monitored as carefully as the ones built in-house. Noble says, You dont get to be a Boeing supplier in the first place unless you have demonstrated that you have the capability. And after that, the Supplier Management organization continues to monitor you through the supplier quality conformance process. That means we are monitoring the progress, the processeshow the part is actually madeand the quality.

Today, the 787 program has more than forty top-tier supplierscompanies that work directly with Boeingand hundreds of other companies that provide items from fasteners to fasten seat belt signs. Top-tier suppliers contribute a wide range of 787 componentspassenger doors and global collaboration tools and software from France; a cabin air purification system from Minnesota; tires, in-flight entertainment systems, and wing boxes from Japan; pumps, valves, and engines from the United Kingdom; the horizontal stabilizer and central fuselage from Italy; a fire protection system from North Carolina; electrochromic windows from Alabama; cargo doors from Sweden; and raked wing tips from Korea. These are just a few examples of items that come together at final assembly in Everett, Washington, or at the integration facility in Charleston, South Carolina. Many Boeing suppliers geared up for the 787 by making big investments of their own. Eleven partners from around the world completed facility construction for a total of three million additional square feet to create their major structures and bring the next new airplane to market.

Boeing Supplier Management ensures that the suppliers parts will integrate with the rest of the airplane and that they meet predetermined quality standards. There are representatives in factories of suppliers around the world, especially in the initial development stages of innovation and testing. Supplier Management also negotiates and manages all the contracts, requirements, and schedules that cover all those parts.

According to Noble, From the design side the engineers have to make sure that all the designs of components are going to work together to make a flying machine. From the manufacturing side, we also need to understand in what order to put the parts together. I think of it as a puzzle. As we build, we are defining what we call the condition of assembly. The puzzle for manufacturing and operations people is to figure out the very best condition of assembly.

These assembly specifications are carefully defined and are passed through a complex software system in which drawings and other data flow, from design and manufacturing engineering to the small personal laptopscalled electronic tabletsthat mechanics use on the factory floor.

The mechanics electronic tablets provide step-by-step instructions in four-hour work increments, as well as links to design drawings. The instructions explain in what sequence and to what specifications every bolt is installed. Assembling in the right order is crucial to smooth flow. The idea is to prevent reworkremoving something thats already been installed in order to install something else.

Just as there are Boeing personnel at supplier sites, suppliers send their own representatives to final assembly areas to confer on integration and quality. Many languages are heard at the coffee shops at the Everett facility. Noble says, Theres nothing like human-to-human integration to ensure everything is integrated, installed, and functioning.

Theres plenty of virtual communication, too. Boeing and its top-tier suppliers are connected virtually at about 135 sites around the world.

The Lure of Composites

The logistics of managing a vast supply chain is a huge part of the story of how 787 components come together. But because of its composite structure, the 787 has dramatically changed the way this happens and the scale of operations.

Of the 20 percent reduction in fuel burn achieved by the 787, 3 percent can be attributed to the materials used to build the new airplane. Structures made of composite materials are stronger, stiffer, and lighter20 to 30 percent lighter than comparable aluminum structures. They dont corrode and they are more resistant to fatigue and damage than metallic structures.

The 787 Dreamliner uses composites as its primary structural material. There is still metal on the 787aluminum, titanium, and steel. Composites are used where they provide important benefits and cover a wide area of the airplane, including the wings and fuselage.

Composite material typically consists of high-strength fibers embedded in a resin matrix, such as epoxy. This material is applied to shaped molds in a process called lay-up. The finished lay-up is then cured in an autoclave that supplies heat and pressure to form finished parts and structures. Its kind of like baking a cake. Excess material is trimmed to the correct shape, and then the parts are inspected.

Robert Noble says, One of the toughest things about this airplane has been working at a new scale with a new material. Everyone, no matter how much experience they have, gets trained to do it a new way. Everybody.