With the high demand of healthcare services in general population, the cost in healthcare expenses continuously increased globally [].

Titanium alloys serving as implantable materials have been applied in medical and dental applications for over 70 years. Currently, the most commonly used titanium alloys are pure titanium and Ti-6Al-4V as well as Ti-6Al-7Nb alloy. In spite of the poor corrosion resistance of pure titanium in physiological environment, it is also mechanically weaker and easily wear-out. Consequently, the use of pure titanium is limited in load bearing implants except in dental cosmetology [].

Not only does the Ti-6Al-4V alloy contain toxic elements of Al and V, but also the Youngs modulus of this alloy is much higher than that of human bones. These undesired properties might complicate the clinical outcomes due to stress shielding effect, bone resorption, and even implant loosening [].

+ TITANIUM ALLOYS IN BIOMEDICAL APPLICATIONS

Few metals with excellent mechanical properties and corrosion resistance have been widely used in hard tissue replacement such as total hip and total knee arthroplasties, artificial intervertebral disc, Pedicle screw and other instrumented spinal arthrodesis in spinal surgeries as well as dental implants. Other popular applications include intravascular stents, catheters, orthodontics arch wires and cochlear implants etc. The details are summarized in Table .

Table 1

Traditional metallic materials for biomedical application.| Alloys | Phase | Countries | Integrated Properties | Applications/

Standards |

|---|

Pure Titanium

TA1ELI, TA1,

TA2, TA3,

TA4 | Various | Rm 200 ~ 580MPa,

As 15 ~ 30%,

Z 25 ~ 30%,

E = 100GPa | Orthopedics, dentistry/ International standard, Chinese national standard

(Widely used) |

| Ti-6Al-4V | + | Various | Rm 825 ~ 930MPa,

As 15 ~ 25%,

Z 25%,

E = 120GPa | Orthopedics, dentistry/ International standard, Chinese national standard

(Widely used) |

| Ti-6Al-7Nb | + | Swiss-invented

Various | Rm 750MPa,

As 12%,

E = 106GPa | Orthopedics, dentistry/ International standard, Chinese national standard

(Widely used) |

| Ti-5Al-2.5Fe | + | German-invented

Various | Rm 1020MPa,

As 10%,

E = 112GPa | Orthopedics/ International standard, Chinese national standard

(Discarded) |

| Ti-2Al-2Mo-2Zr | near | China invented | Rm 750MPa,

As 25%,

E = 105GPa | Orthopedics, dentistry, limited use in ocean engineering |

| TiNi | Martensite | Various | Rm 1200MPa,

As 25%,

E 40GPa | Orthopedics, dentistry, vascular interventions/ International standard, Chinese national standard

(Widely used) |

Most of the elements e.g. Fe, Cr, Co, Ni, Ti, Ta, Nb, Mo, W in the current implantable metals served as trace elements in human body. Indeed, small amount of these trace elements are crucial to human metabolism. For example, Fe element can keep the normal function of red blood cells, and Co element can maintain vitamin B12 synthesis []. In the literatures, tiny amount of V in bone, liver, kidney and spleen would significantly interfere the phosphates metabolism of cells, thereby directly affecting the Na+, K+, Ca+, and H+ and reaction with ATP enzyme. Without considering the toxicity of V element, the literatures reported that another element of Al in these alloys not only damaged the organs, but might also potentially result to osteomalacia, anemia, and neurological disorders due to the accumulation of aluminum salts in vivo.

In the middle 1980s, Switzerland and Germany had jointly developed the second generation of V-free + titanium alloys i.e. Ti-6Al-7Nb and Ti-5Al-2.5Fe alloys []. To overcome these complications, materials scientists have endeavored to develop highly biocompatible, lower modulus and mechanically match titanium materials.

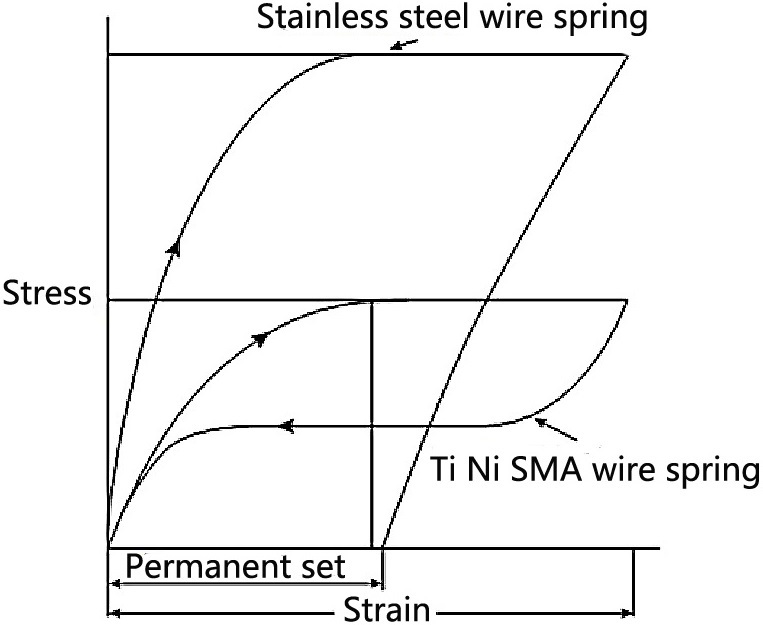

TiNi alloys have a special mechanical property named shape memory effect (SME) that enables the recovery from deformation after being heated. The shape memory effect was firstly discovered by Buehler and Wiley from the US Naval Ordnance Laboratory in 1963 [), when strain increases beyond to the initial elastic zone, the stress will be maintained at the same level despite of the strain increased. While unloading the NiTi material, the stress will be then maintained at lower level of stress as the strain reduced. With further reduction of strain, the NiTi wire recovers to initial length without any permanent deformation. Indeed, the super-elastic property of NiTi has been widely applied in dental arch wire. The studies demonstrated that the clinical outcome was much better than the correction with the use of traditional stainless steel arch wire.

TITANIUM ALLOYS FOR BIOMEDICAL APPLICATIONS

Current Development of Titanium Alloys

Recently, the invention of new titanium alloys with low modulus has attracted a lot of attentions in particular to the countries such as USA, Japan, South Korea and China. The most popular titanium alloys include Ti-Mo, Ti-Nb, Ti-Ta or Ti-Zr that have been widely applied in biomedical fields []. Among the other commonly used titanium alloys, these newly fabricated titanium alloys have lower modulus and higher strength due to the contribution of the aforementioned

Fig. (1)) Schematic illustration of the stainless steel wire and TiNi SMA wire springs for orthodontic archwire behavior.

elements. Particularly, the Ti-Nb matrix alloy with the combination of nontoxic elements including Nb, Ta and Zr enables not only the lowest modulus among the others, but also excellent shape memory effect. Therefore, this new alloy has great potential in clinical applications and is a highlighted biomedical metal in the field today. Some of the Ti-Nb matrix metastable alloys have already been used practically for example Ti-13Nb-13Zr [].

Design of Titanium Alloys

To develop high performance biomedical titanium alloys, pre-designing and relative mechanical properties calculation are of the most important points to consider. First of all, researchers may count on d-electron alloy design method to design their desired materials by calculating the orbital parameters