The Electrokinetic Recovery of Tungsten and Removal of Arsenic from Mining Secondary Resources: The Case of the Panasqueira Mine

Joana Almeida1,2, Paulina Faria2,3, Antnio Santos Silva4, Eduardo P. Mateus1, and Alexandra B. Ribeiro1

CENSE Center for Environmental and Sustainability Research, Department of Environmental Sciences and Engineering, NOVA School of Science and Technology, NOVA University Lisbon, 2829516 Caparica, Portugal

Department of Civil Engineering, NOVA School of Science and Technology, NOVA University Lisbon, 2829516 Caparica, Portugal

CERIS Civil Engineering Research and Innovation for Sustainability, Instituto Superior Tcnico, University of Lisbon, 1049001 Lisbon, Portugal

Department of Materials, National Laboratory for Civil Engineering, 1700066 Lisbon, Portugal

4.1 Introduction

Mining industries today are producing a larger volume of residues than ever. To access ore, waste rock needs to be removed, and other residues are generated in the process [].

The electrodialytic (ED) process has been studied to remove metals and metal oxides from a wide range of porous solid matrices in the environment [].

Natural deep eutectic solvents and/or ED processes were applied to secondary mining resources from the Panasqueira mine to remove or separate elements [].

Additionally, worldwide, construction products have extremely high embodied energy and consume large amounts of raw materials. EU targets from 2021 to 2030 [] call for reducing greenhouse gas emissions by 40% (comparing with 1990 levels) and improving energy efficiency by more than 32.5%. The valorization of residues as binder replacers or additions in cementitious construction products may be a sustainable alternative for the construction and mining sectors, alleviating primary resources needs and residues disposal.

Mining wastes from the Panasqueira mine have been successfully reused in the construction sector using different approaches []. The feasibility of innovative technologies, namely the ED process, to remove and recover elements from secondary resources for subsequent use in construction product formulations was also studied.

4.2 Tungsten Mining Resources: The Panasqueira Mine

4.2.1 The Development of the Industry

The Panasqueira mine is located in the Centro region of Portugal and is described as the largest SnW deposit in Western Europe [).

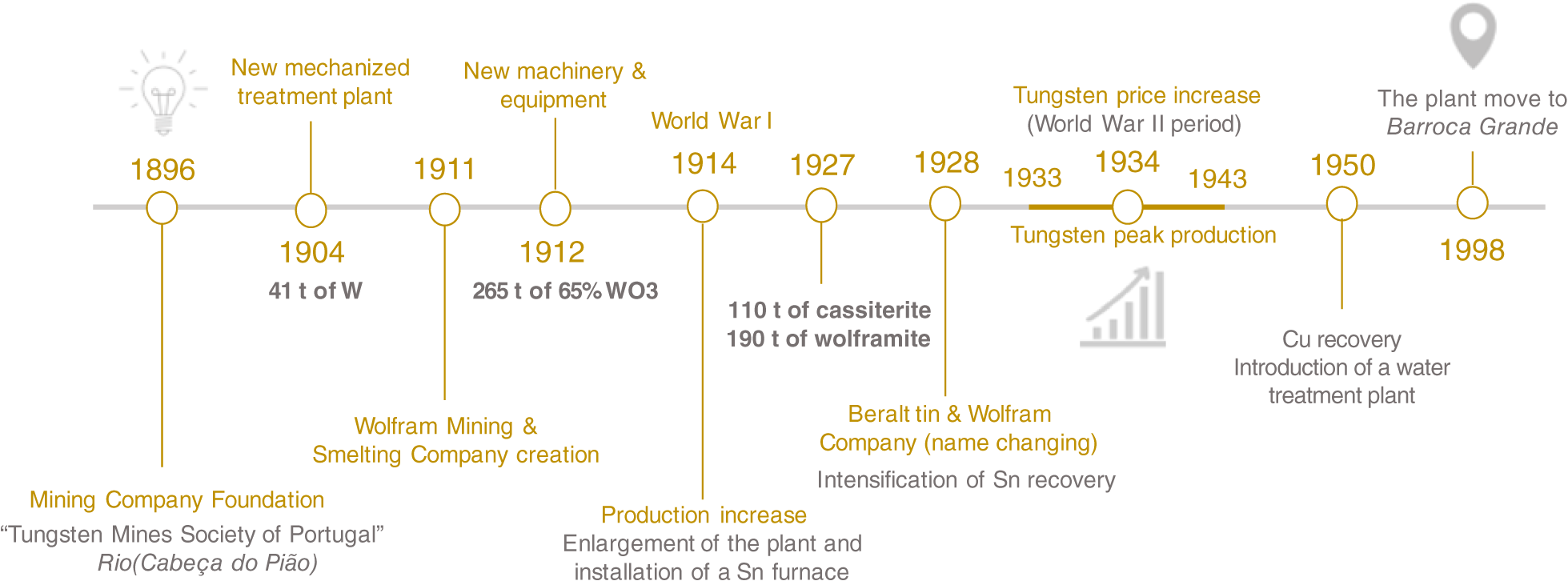

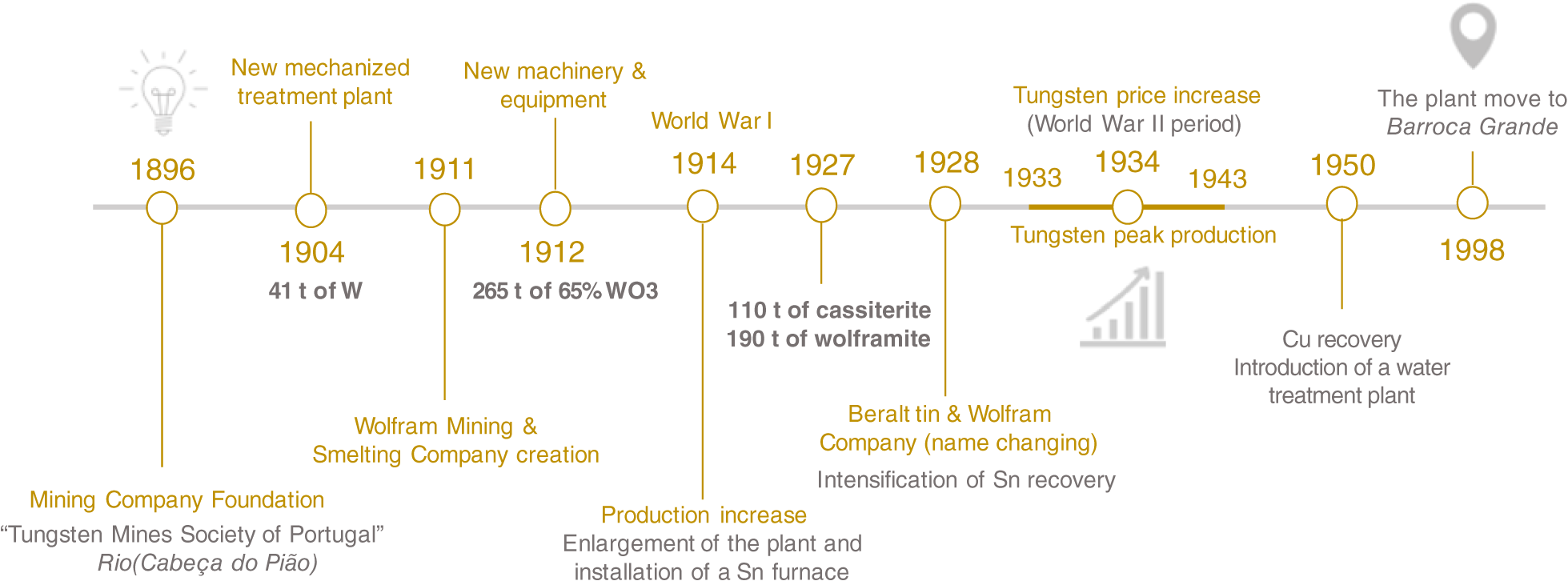

Highlights of the Panasqueira mine timeline.

Panasqueira began W exploration in 1896, when the mining company Tungsten Mines Society of Portugal was founded. Wolframite ore was firstly extracted from Cabeo do Pio (now known as Rio). In 1904, the plant was improved, and 41t of ore were produced by integrating a new mechanized treatment using the Zzere river for water supply. Although the first underground drifts were opened in Rio, mining activities decreased at this site due to richer veins in the Panasqueira area [].

In 1911, Wolfram Mining and Smelting Company was formed and acquired all the rights and concessions of the previous company. Investments in machinery and equipment were made to increase ore production. From a social perspective, the need for more workers to manage the plant processes increased employment in the region. The production of wolframite concentrates was estimated to be 267t of 65% WO3 mined from 11000t of vein and 86000t of host rock [].

During the World War I, the mining operation grew, production increased, and the plant facilities were enlarged. Also, the mine began to recover Sn from cassiterite. In 1928, the price of W fluctuated, which affected its exploration. To overcome the W crisis, the recovery of Sn was intensified. The company reorganized itself and changed its name to Beralt Tin and Wolfram Company [].

During the World War II, peak production of W was reported, and the price of W increased again in 1934. Manpower was also boosted from 750 workers in 1933 to 5800 in 1943. However, from the end of the war to 1950, the W market declined. The production of Sn was maintained, and copper (Cu) recovery was introduced to the plant to compensate for W depreciation. In addition, water treatment was integrated into the system to address water quality issues. The Zzere river is one of Lisbons water supplies, so constant water monitoring is necessary [].

Later, the company mechanized underground operations, reducing labor expenses. In 1998, the remaining plant at Rio was moved to Barroca Grande, where it is located today. The mine has a production plan for more than 30years in the future [].

4.2.2 Ore Extraction Processes

Tungsten is a high valuable transition metal that can be extracted from the two W minerals that are commercially mined: scheelite (CaWO4) and wolframite ((Fe, Mn)WO4) [].

The current extraction technology is based on a roomandpillar method, taking into account an analysis of the geomechanical and geological properties of the rock mass. The ore extraction process starts with a heavy media separation between fine and coarse fractions. This step removes 80% of the ore that does not contain W. Then, this preconcentrated fraction is subjected to a conventional gravity concentration technique, followed by flotation (with sulfide) and dry magnetic separation [].

4.2.3 Potential Risks

The final concentrate production procedures are carried out in the Barroca Grande plant. A huge tailings pile and two mud dams are currently in the area. One dam is still being filled with material (mud and coarse material) without W ore as a result of extraction operations [].

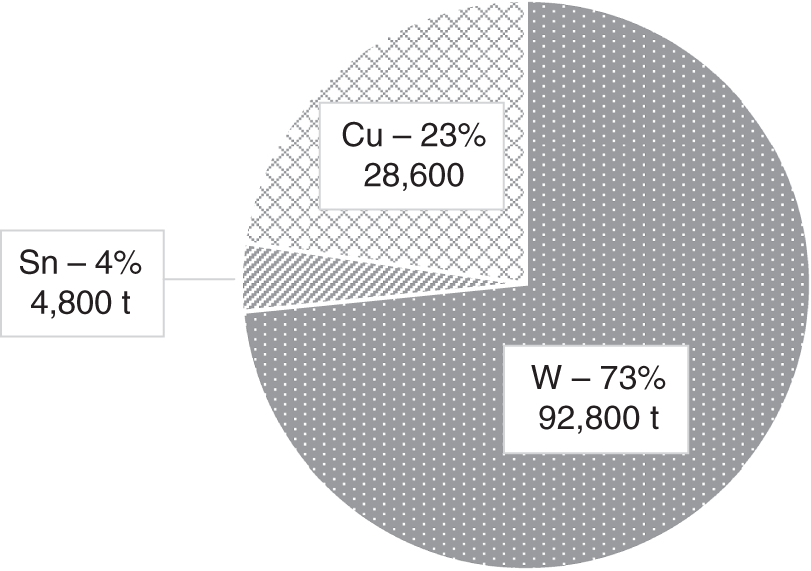

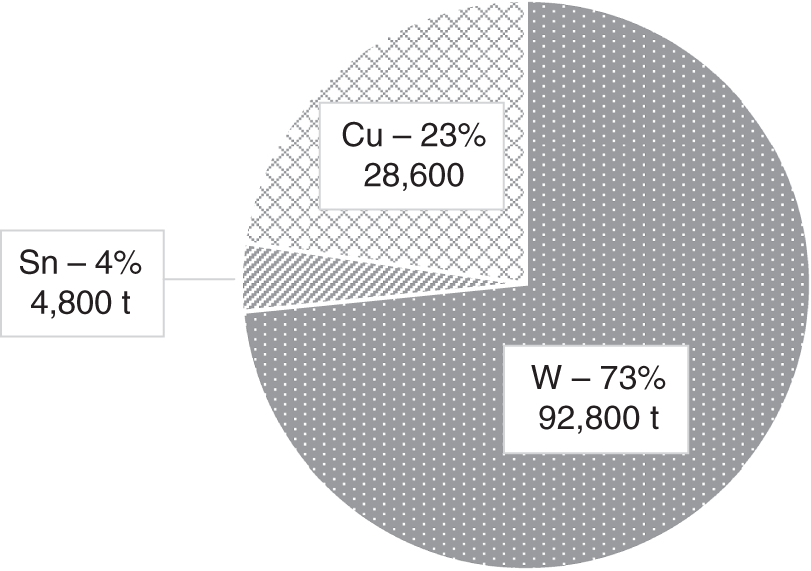

More than 27milliont of rock were extracted in the first 50years of mining. During this period, around 92800t of W concentrate, 4800t of Sn concentrate, and 28600t of Cu concentrate were produced [).

]).

Now production has been optimized and is estimated to yield 8500095000t of W concentrate per year, which is almost equal to the total W production during the first 50years of Panasqueira mining. Currently, the W concentrate grade is approximately 75% WO3, representing one of the best W products available on the global market [].

Panasqueira extraction and processing generate two types of mine tailings: (i) coarse wasterock tailings from rock blasting and (ii) wastemud tailings transferred into mud dams. Panasqueira has accumulated these rejected fractions for a long time, and they now have enormous proportions. The total amount of accumulated residues is a problem: it is estimated that to date, 8200000m3 of mining waste have been disposed of. Even more concerning is the quantity of residue disposed of in open air impoundments, since only around 23% of the total mining waste estimated is effectively at dam facilities (1924919m3) [].

Besides harming the landscape, the piles of accumulated mining waste are exposed to environmental conditions. Thus, these residue impoundments are unstable and prone to landslides, erosion, and leaching of harmful compounds. Waste mud contains high proportions of arsenic and other sulfiderelated heavy metals, e.g. lead (Pb), Cu, cadmium (Cd) and zinc (Zn). The oxidation of sulfides and their release from open impoundments are reported as the main threat to the Panasqueira area since they are associated with the migration and mobilization of metals/metalloids into the environment [].