Old Cars

Auto Restoration

Guide Vol. II

Advice and How-To Projects for Your Collector Car

CONTENTS

FOREWORD

It is for all the old car hobbyists out there turning their own wrenches and bloodying their own knuckles that we offer the second volume of Old Cars Weeklys Auto Restoration Guide. Inside we offer restoration advice and how-to information from a variety of professional sources, as well as from regular Joes who just happen to know a lot about fixing and restoring vintage cars.

We get inspired hearing all the stories from car owners about their struggles and triumphs with their antique vehicles. Hopefully, this book supplies a little inspiration in return.

From the staff at Old Cars Weekly and Old Cars Report Price Guide

SECTION ONE

EXTERIORS

FITTING FENDERS

Saved by shims: How little things can make big differences

Story and photos by Rotten Rodney Bauman

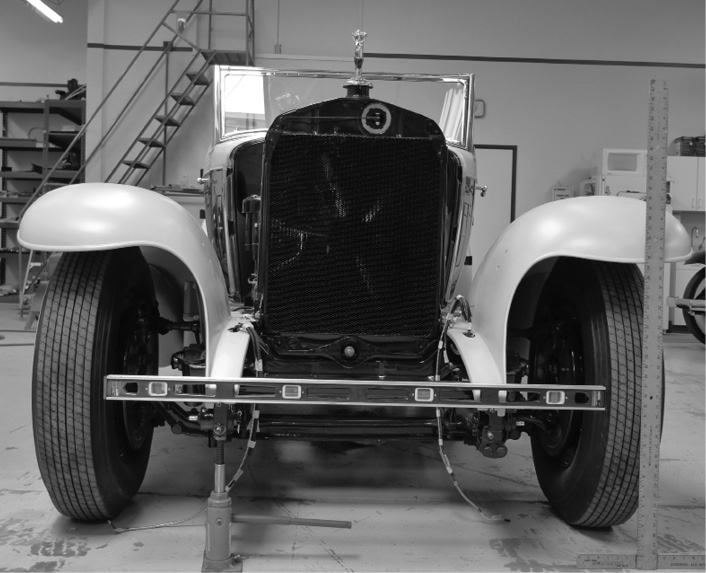

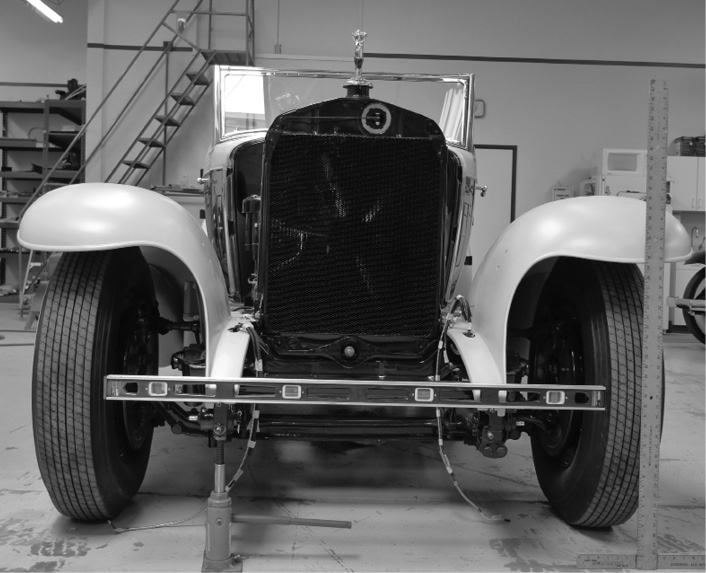

It was a long haul, but this long-ongoing 31 Cadillac V-12 convertible coupe project was a runner by the time we were ready to paint and complete the final installation of the fenders. The body was resplendent in green with black reveals. The fenders and aprons would soon be black as well. We had a trimmer working on the car and the painter in me was pretty protective at times like these. However, as it turned out, our trimmer of choice was actually quite conscientious and he did a bitching job while I was painting little pieces and working the fenders.

Before I put the fenders in color, I wanted to verify that they were going to fit as well as the rest of the car. We worked hard to fit the gaps on this old wood-framed body. The fenders had been fit to the car before, but that was in the early stages of the restoration and they had been hammered a lot since then. So, a double-check for fender fitment was good insurance while they were still in first-round primer-surfacer.

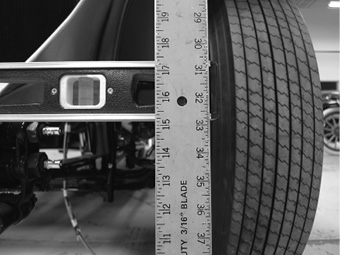

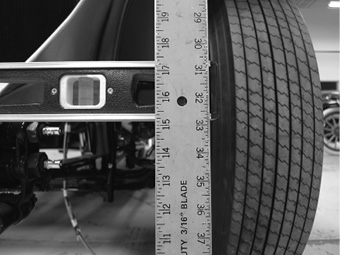

Before any serious scrutinizing took place, and before any measurements were recorded, we checked for even tire inflation all the way around. A measuring stick confirmed that the passengers side frame horn was a little closer to the shop floor than the left. A weak spring could have been the culprit, but that could be addressed at a later date. For this fender fitment inspection, we needed the frame level, which we temporarily accomplished with a little help from a level, a measuring stick and a small hydraulic bottle jack.

In the beginning, it was business as usual. With the cars weight on its suspension and even tire inflation, a bottle jack was positioned under the sagging passengers side frame horn. Then a long level was laid across the shanks of the upper bumper studs.

Some minor leveling adjustments had to be made. The bottle jack helped through this phase so we could diagnose the source of the sag with the fenders safely removed from the car.

After some adjustment, we were satisfied that the frame was level. However, just out of view at the front fender tips, we already saw the twist in the fender. These fenders are very strong. Its not like they can be bent around like a same-vintage Ford.

What started out as a standard, straight-forward procedure took a surprising twist in the form of a twisted drivers side front fender. In short order, I embarked upon an emotional rollercoaster ride which took a lot out of the lil old auto restorer in me.

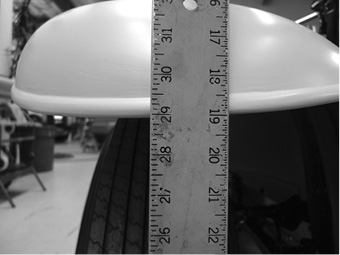

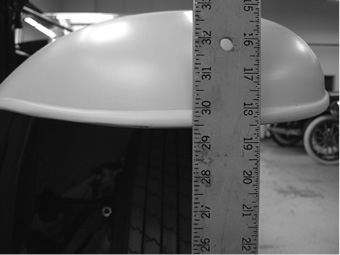

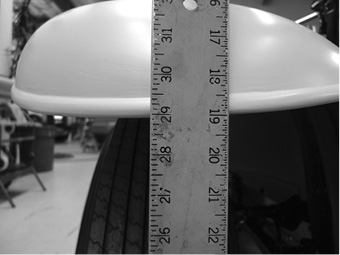

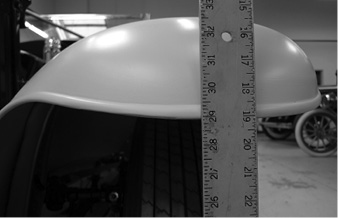

With the centers of the tires treads gun-sighted, the measuring stick didnt lie. Although the frame was now level, there was still a half-inch difference in height from the shop floor to the fender bead. Even without the measuring stick, the problem was obvious, and at this point, the shapes of the fender tips also appeared to vary.

As luck would have it, these fender braces only bolt to the sides of the frame. There are four bolts in a fairly square arrangement. It appeared a pair of shims added at the upper bolts between the left brace and frame rail were all that was needed to lower the fender.

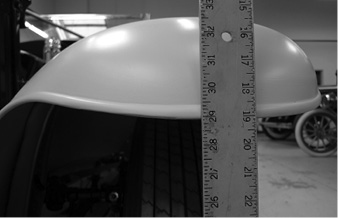

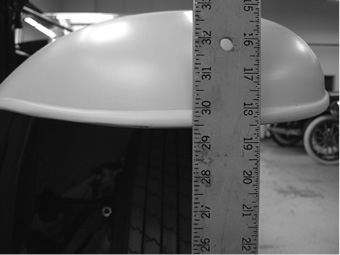

Heres just another example of how little things can make big differences. In this particular instance, two small (1/8-inch-thick) Au-ve-co body shims all but cured the fender fitment issue.

The fenders now looked as though they could have been stamped by the same manufacturer. The angle at the bead has also improved visually and from here, I had little doubt that Id be able to dial them in further during final assembly.

You can only do so much with a box of shims, but this time were getting off easy, thanks to a restless nights sleep and Au-ve-co Products shims.

What youre about to witness made me sick at first glance. So, I devoured a large habanero, anchovy and headcheese pizza, had a beer and called it a night. The perplexing problems simple solution came to me in a warped and twisted dream a warped n twisted fender dream.

Source

Au-ve-co Products

www.auveco.com

BACKTRACKIN FOR GAPS

An out-of-sequence solution for bad panel alignment