First published in 2014 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

The Crowood Press 2014

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 680 2

Safety is of the utmost importance in every aspect of metalworking. The practical workshop procedures and the tools and equipment used in metalworking are potentially dangerous. Tools should be used in strict accordance with the manufacturers recommended procedures and current health and safety regulations. The author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

Photography by Colin Mills

Dedication

To Susan Elizabeth Tindell (19492012).

Contents

Preface

In a parallel universe there may exist the perfect material as strong as an alloy steel, hard as diamond, malleable as gold, corrosion-resistant as titanium, weldable as mild steel, cheap as grey cast iron, abundant as wood, long-lasting as flint, etc. But, alas, it doesnt occur here, hence the need to understand and select from the myriad materials commonly available. There are, for instance, literally thousands of different steels produced worldwide, although we need only know the details of a tiny selection.

Whilst the material in a project usually accounts for only a small part of the cost and it is then the subject of considerable added value in processing (e.g. machining) it is surely appropriate to avoid this effort being wasted on the wrong material. Apparently invulnerable items may be rendered useless by the insidious effects of, for instance, vibration (slow crack growth fatigue); stress-corrosion cracking (austenitic stainless steel in certain environments); or fatally cracked (incorrect welding procedure for a low-alloy steel).

This book should help as a guide through the labyrinth that is engineering material applications, based on well-established theory and practically available materials.

Henry Tindell

Cheadle Hulme, 2013

Introduction

Its better to burn than rust, sang the Eagles in 1972 but, like the Rolling Stones, forty years later theyve discovered that its better to rust gently than burn, just like my old bike

For those of the gently rusting persuasion, this book aims to explain the application of engineering materials, essentially metals, for the engineer who is concerned with making things. The model engineer, the amateur or even professional experimental engineer, really needs a basic feeling for materials otherwise a lot of the enjoyment of these activities will never be realized; not to mention the pitfalls into which the unwary can fall, with expensive failures incurring lost time, money or worse

In the post-industrial age now upon the West, practical skills and knowledge are at a premium, for not all things can be facilitated directly from the virtual world. And there is, despite the present information revolution, a common lack of basic understanding of the materials used in making things.

Metals have become ubiquitous since the early twentieth century; like computers in our age they are often overlooked. The great advances in understanding of metals behaviour, with many discoveries as recently as in the last fifty-odd years, may not be apparent to the non-specialist worker. Understanding how metals work has increasingly become the province of the materials specialist, as Further and Higher Education courses have moved on from metallurgy to the newer materials like plastics and composites, with computer modelling rather than hands-on engagement. This is all very well, but it is leaving a great hole for expertise in the shed, when a substantial industrial manufacturing facility cannot be called upon for support.

Even a generation ago, it was not uncommon (in the UK, at least) for an engineering firm to be sufficiently vertically integrated that many trades were available in-house, from departments for electrics, plumbing and joinery, to design, fabrication, foundry-work, mechanical and non-destructive testing even metallurgical analysis. This meant that often substantial domestic jobs could be tackled with access to these trades, like re-wiring a house and shed, or fitting a central heating system. It provided a source of material knowledge, even the materials themselves, for that special model or vehicle repair. (A downside of the latter I once saw was when a lunchtime welding repair on a car ended in it catching alight and being written off but thats the cost of experience!) Nowadays, this scenario is rare and the enterprising individual has to look elsewhere for help and guidance, with the result that an understanding of materials is becoming an impoverished area of expertise. There is, perhaps, a parallel with cooking, where time and circumstances have tempted a generation away from individual food preparation skills and into fast foods and takeaways. The burgeoning interest in cooking programmes and literature, however, shows the inherent desire for a practical connection with the process the making things drive, not dissimilar to that of the practical engineer.

Photo 1 Horizontal boiler, for use with a steam engine in a glass fibre model boat.

Photo 2 Vertical boiler, delivering 30psi, to power a Viper Vee twin, oscillator steam engine.

Photo 3 Early twentieth century vertical steam engine, from a German manufacturer.

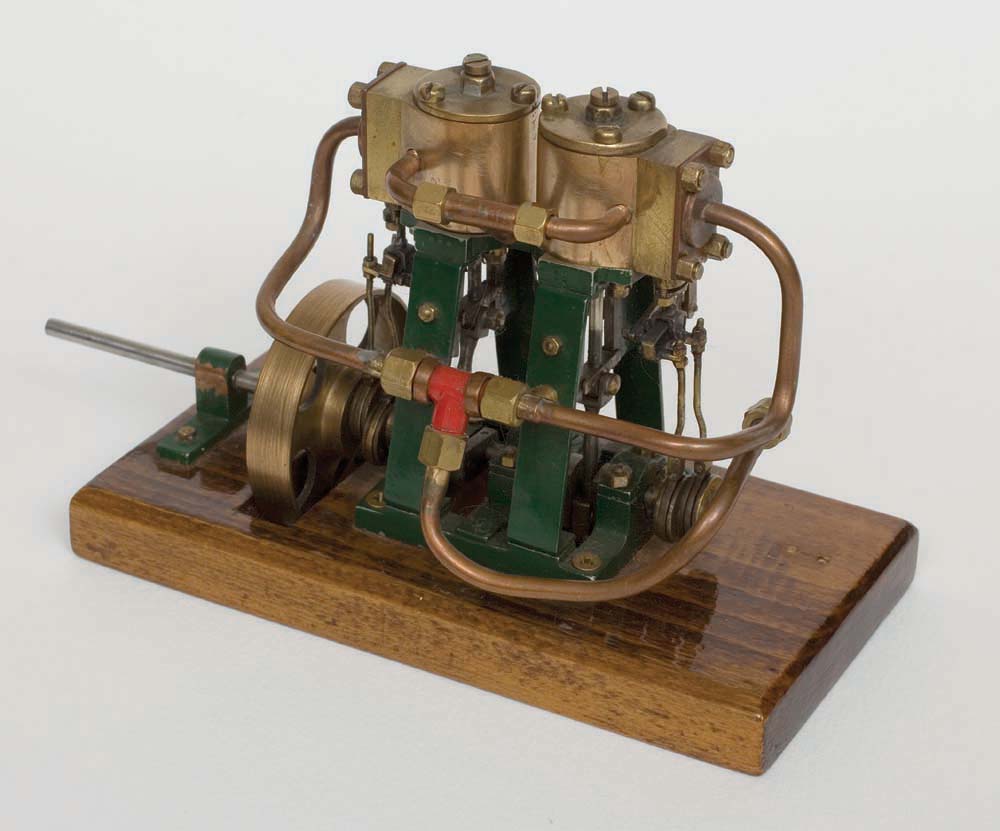

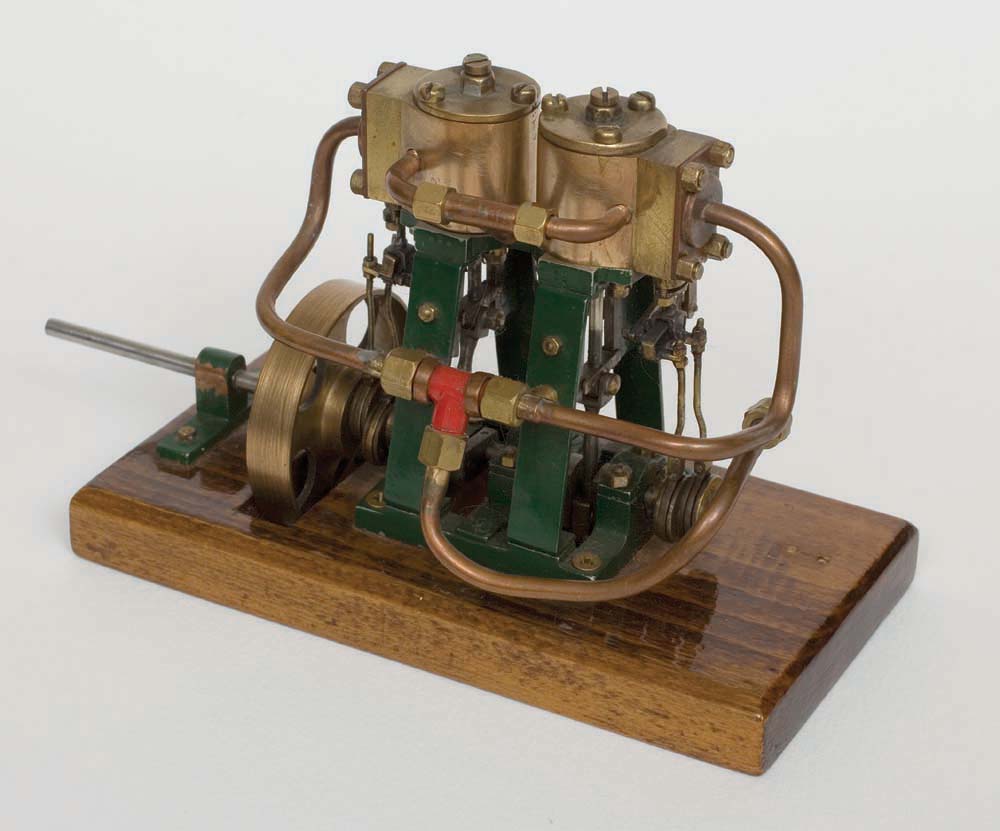

Photo 4 Vertical parallel twin cylinder marine engine, often adapted as factory power source.

In this increasingly ethereal world of the virtual image, the benefit of making real things can be remarkably therapeutic, but in materials-driven engineering projects large or small, information and experience need to be steadily gained or disappointment and failure can overwhelm the enthusiastic worker. So, this book tries to describe the metals commonly available to the general enthusiast and how they can be selected and processed to a satisfactory product. As importantly, it points to the limitations of metals an area that demands sufficient knowledge and experience.

Next page