First published in 2014 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2014

The Crowood Press 2014

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 775 5

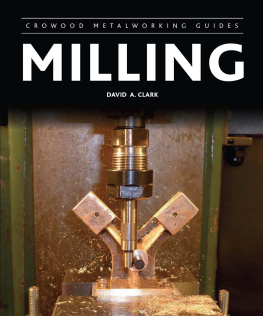

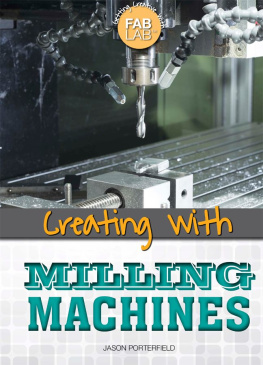

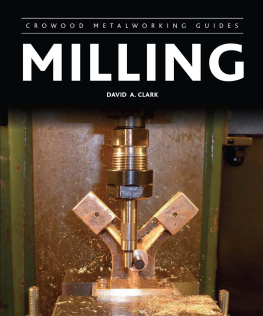

Frontispiece:

A Tom Senior light vertical milling machine suitable for use in a small workshop.

Acknowledgements

I would like to thank the following for the use of some of their illustrations: Arc Euro Trade, MyHobbyStore Ltd (Publishers of Model Engineer and Model Engineers Workshop), Warco and Ken Willson.

Contents

Introduction

This book will assist the reader in developing their milling skills and applying them to make finished pieces of work accurately and to very high standards. If you are an amateur or professional engineer who is perhaps looking to install your first milling machine in your own workshop, this book is for you. It is a complete comprehensive guide to buying, installing and using a small milling machine, with the accessories that you will need to use the milling machine to its full capabilities. The book will teach you milling from the basic principles right through to advanced milling methods. Whether you are working in a home or light industrial environment, you will learn the important milling skills and insider tips from someone who has spent a large part of his life milling in industry.

There are several types of milling machine such as CNC mills, horizontal mills, vertical mills and machining centres. The milling machine we will concentrate on is the vertical mill and the vertical turret mill, which are the ones that will be most likely to be found in the small workshop. Many of the principles of milling apply to the entire range of milling machines so this book will be useful to, say, the horizontal milling machine owner as well as the CNC milling machine owner. The milling machine is very versatile at a pinch it can also be used as a simple lathe by holding the workpiece in the milling machine spindle and a lathe tool in the machine vice.

ABOUT THE AUTHOR

I spent more than thirty years in the engineering industry, mostly doing milling in all its forms. I was trained to make industrial sewing machine components which, as you can imagine, are mostly very small and were made to very tight tolerances. I also worked on the huge wing holding fixture used by Airbus to transport wings in their Supper Guppy aircraft. I have also trained many people in milling machine practice and engineering in general.

I was the editor of Model Engineer magazine for about five years and I edited Model Engineers Workshop from 2007 to 2014; these are the two main UK magazines for machining in the home workshop. This editing experience has given me a unique insight into what amateur engineers need to help them succeed. This book will enable you to get started with a milling machine in your workshop easily and, most importantly, safely.

Model Engineers Workshop magazine, first published in 1990, is a recent addition to the model engineering scene. It often covers projects and techniques suitable for the milling machine. A new issue goes on sale every four weeks.

The Model Engineer magazine is probably the worlds longest running model engineering hobby magazine and is published every fortnight. It is mainly about making precision models but often includes articles about milling machines. The milling machine depicted on the cover of the issue shown is a model of a horizontal milling machine made by Ray Griffin.

WHY DID I WRITE THIS BOOK?

I have worked with many engineers, both beginners and experts, and have taught many young people during their first steps into engineering. When I worked in the engineering industry, mainly on milling machines, I found ways to work quickly and accurately, very important when you were self-employed and did not get paid if you scrapped a job. I learnt a lot from many expert engineers and also by machining many different types of component. I would like to pass some of this knowledge on to you, the reader. When you have learnt all about milling, you may in turn teach someone, perhaps a grandchild, all they need to know about milling.

A milling machine is very useful and will contribute greatly to the success of a workshop. The lathe is often called the king of machine tools. I consider the milling machine to be a close second to the lathe but really, the milling machine is far more versatile than the lathe. In industry, most millers can do turning, but often the turners do not know how to mill. The same applies to CNC millers in industry; most CNC millers think they can mill but usually, unless they went through the manual milling training stage, the majority of CNC millers are just programmers who know how to program and set up a CNC milling machine but do not know the correct way to mill.

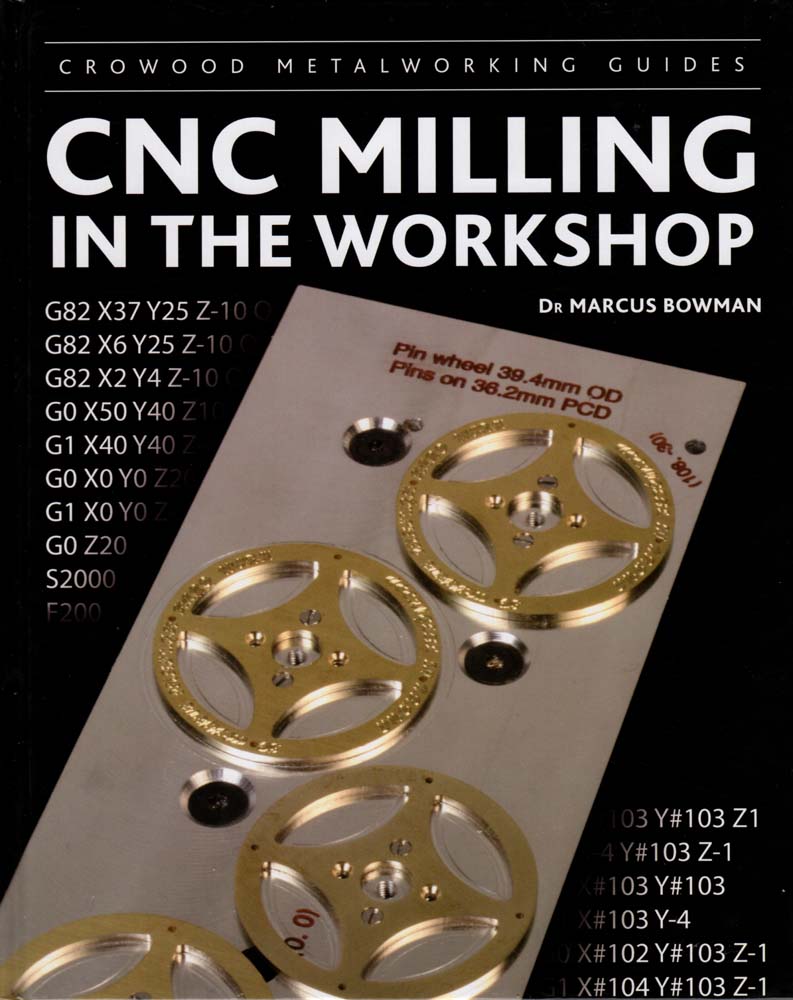

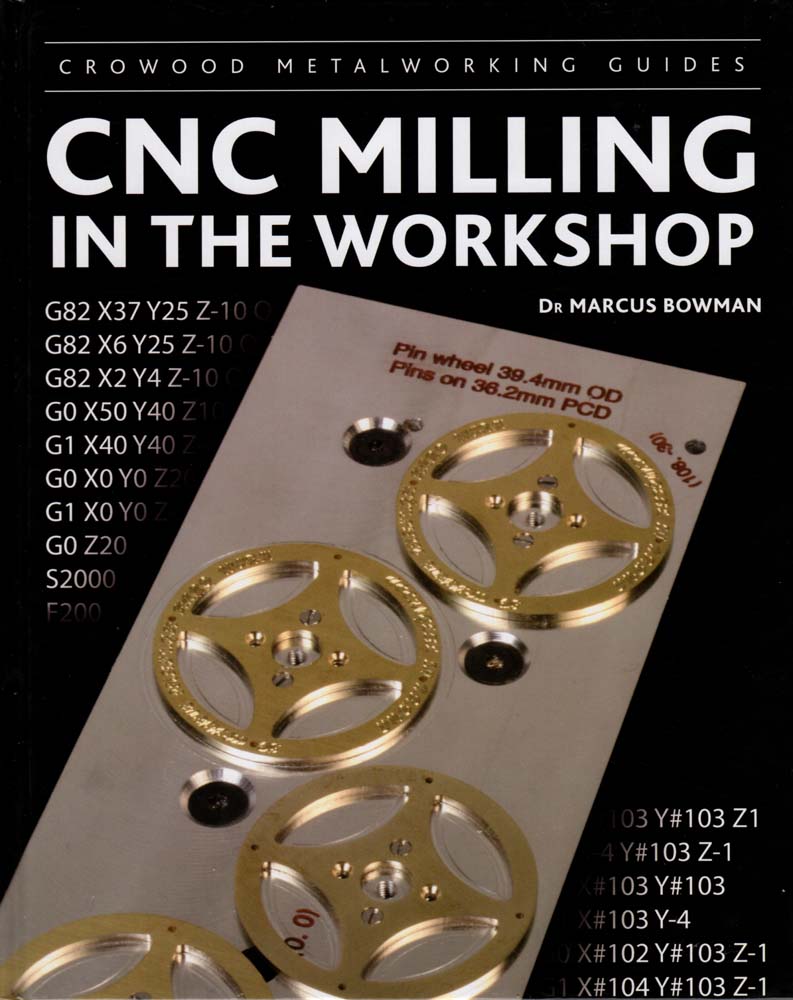

I will be concentrating on the vertical milling machine rather than the horizontal milling machine. Also, although this book is a complete introduction to milling, it does not cover CNC milling. If you wish to learn CNC milling, this book is still ideal for learning the basics of CNC milling as the basic principles are the same, but the programming side of CNC can be learnt from Dr Marcus Bowmans book CNC Milling in the Workshop in the Crowood Metalworking Guides series of books. Marcus Bowmans book is an ideal companion to this book if you are considering buying a CNC mill.

Dr Marcus Bowmans book in the Crowood Metalworking Guides series is an excellent introduction to CNC milling.

WHAT YOU WILL LEARN FROM THIS BOOK

Following a brief history of the different types of milling machine and their uses, we will consider how to choose a milling machine depending on what you want to do with it. What is the largest size of work you are likely to want to machine? What speeds are required? What size of milling machine should you buy? What features are desirable?

Next page