Benjamin Sweeney - Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean

Here you can read online Benjamin Sweeney - Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2017, publisher: Clydebank Media, genre: Business. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean

- Author:

- Publisher:Clydebank Media

- Genre:

- Year:2017

- Rating:4 / 5

- Favourites:Add to favourites

- Your mark:

- 80

- 1

- 2

- 3

- 4

- 5

Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

Contents

Terms displayed in bold italic can be found defined in the glossary

DOWNLOAD YOUR FREE DIGITAL ASSETS!

Visit the URL below to access your free Digital Asset files that are included with the purchase of this book.

DOWNLOAD YOURS HERE:

www.clydebankmedia.com/lean-assets

Introduction

The Lean model for production and manufacturing is a collection of business practices, strategies, and methods that focus on waste elimination and continuous improvement within an organization. Often referred to simply as Lean, this business model has applications in every industry, not just the world of manufacturing. All businesses, and many organizations outside the business world, can benefit from Leans rigorous and vigilant approach to waste reduction and efficiency.

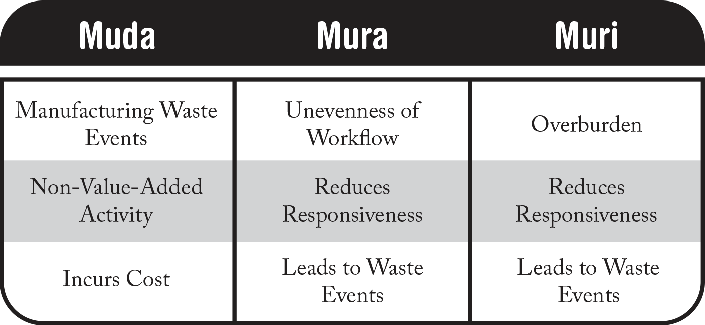

Lean is a management philosophy with a holistic approach that was interpreted from the Toyota Production System , an operations and corporate culture system developed by the popular and highly successful automobile manufacturer, Toyota. At the center of the Lean business concept is the effort to eliminate three types of manufacturing variation and waste: muda, mura, and muri.

Muda represents waste in its most physical form, and it directly translates from Japanese as futility or uselessness. The objective with waste reduction and elimination is to clearly separate the value-added activities from the activities that are identified as wasteful or non-value-added . Muda is the easiest form of waste to understand. It is what many organizations would traditionally classify as waste: defective production, time spent performing non-value-added activities, unnecessary inventory, etc. These specific forms of waste, as well as several other sources of muda, are identified and outlined in detail in the next section.

Mura is waste in the sense of unevenness. Distinct from muda and muri, mura is less easily quantified, though no less impactful on operations. Unevenness in workflow can result in unnecessary downtimes or periods of unnecessary stress on equipment, systems, and workforce. From a management stance, unevenness creates another element that all business practitioners seek to eliminate: uncertainty. Irregular intervals are difficult to predict, and therefore, forecasting becomes difficult. A high degree of uncertainty can greatly reduce the responsiveness of an organizations supply chain. Mindfulness of mura is essential when determining facility layout or assembly protocol as well as understanding and improving the long-term forecasting abilities and short-term processes for an organization and the ability to respond to fluctuating demand.

Muri is a failure to understand capabilities or to succumb to the effects of overburden. This is a tangible concept when applied to facility layout and assembly and manufacturing processes; too much of a workload on a system can cause failure or increase rates of defective production. Overburden in conjunction with unevenness can also create expensive bottlenecking within an organization. Wear and tear on machines or repetitive strain injuries among the workforce can be reduced or alleviated through ensuring that only value-added activities are being performed, as well as through reduction of waste in other areas.

In conjunction with the overriding value of waste reduction through identification and elimination of muda, mura, and muri lies the philosophy of kaizen, or the creation of a culture of continuous improvement. The concept of kaizen is as powerful as it is versatile and, in practice, can be implemented in a multitude of ways that span diverse industries. Kaizen is a mindset as much as a business asset, and represents organizational culture more than a set of manufacturing tools. Permeating all levels of the organization, kaizen not only lays the groundwork for the implementation of Lean, but also guides decision-making, innovation, and improvement at both the micro and macro levels. The concept of kaizen is so powerful that even personal trainers and life coaches use similar approaches with the individual lives of clients seeking to better themselves.

Many aspects of the Lean production system build on this common thread of kaizen and rigorous, continuous improvement. As we explore the world of Lean production, the concept of kaizen, if not implicitly stated, will be evident in best practices and prescribed methods.

Though its origins lie squarely in the manufacturing sector, the less tangible aspects of Lean mean that it can be tailored to fit nearly any organization from the service sector, like healthcare firms, insurance agencies, government agencies, and beyond. Since Lean is a blend of keen, structured business improvement insights and efficient, impactful manufacturing tools, organizations in other industrial sectors can stretch the Lean model to fit their operations. In addition to the data-driven and day-to-day productivity tools that are all part of the Lean toolkit, the real power of Lean lies in the creation of a vigilant mindset among the entire workforce, from workers on the assembly line all the way up to the CEOs office, that the elimination of waste, the need for continuous improvement, and the idea that anyone can effect positive change within the organization are essential for a firms success and longevity.

What follows is a primer on the concepts and ideas that drive the Lean business model and the key components of the winning mindset that keeps contemporary companies on the map.

| 1 | Six Components of Lean Philosophy

- The six components of Lean philosophy are explored in detail

- The D.O.W.N.T.I.M.E. sources of waste are illustrated

- The PDCA method and A3 problem solving approach are explored

While the concepts of waste reduction and continuous improvement exist in all aspects of Lean, there are also six primary qualities that organizations should embody to maintain a competitive, responsive, and flexible position within the marketplace. In many cases, management gurus praise to no end the mindfulness of these qualities as keys to a successful business in todays marketplace regardless of their implementation of Lean. Prior to the leap to Lean, companies should already have a focus on these characteristics in one form or another to establish a solid foundation on which to build the Lean culture. Before the foundational pillars of Lean are addressed, lets look at some basic definitions to better understand the relationship between Lean and value.

At its core, the Lean manufacturing system strives to differentiate between value-added and non-value-added activities. All manufacturing activities incur cost; value-added activities incur cost that can be passed on to the customer. These activities are necessary to produce goods to the customers specifications, though only these activities will generate results that the customer will pay for.

Any other activities are considered non-value-added, and are classified as waste. Waste events are activities that incur cost, but that do not generate more value, utility, or satisfaction for the customer. A well-known culprit of waste (by any definition) is defective production. When a part is generated with a defect, the customer will not pay for that unit. The manufacturer cant insist that the customer pay just because the manufacturer incurred cost in generating the part; there is no value, and the part must be considered a loss.

Font size:

Interval:

Bookmark:

Similar books «Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean»

Look at similar books to Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Lean QuickStart Guide: The Simplified Beginner’s Guide to Lean and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.