MARTIN CHRISTOPHER

Cranfield School of Management

I n recent years there has been a growing recognition that the processes whereby we satisfy customer demands are of critical importance to any organization. These processes are the means by which products are developed, manufactured and delivered to customers and through which the continuing service needs of those customers are met. The logistics concept is the thread that connects these crucial processes and provides the basis for the design of systems that will cost-effectively deliver value to customers.

Accompanying this recognition of the importance of process has been a fundamental shift in the focus of the business towards the marketplace and away from the more inwardly oriented production and sales mentality that previously dominated most industries. This change in orientation has necessitated a review of the means by which customer demand is satisfied hence the dramatic upsurge of interest in logistics as a core business activity.

Recession in many markets, combined with new sources of competition, has raised the consciousness of customers towards value. Value in todays context does not just mean value for money although that is certainly a critical determinant of the purchase decision for many buyers but it also means perceived benefits. Customers increasingly are demanding products with added value, but at lower cost, and hence the new competitive imperative is to seek out ways to achieve precisely that.

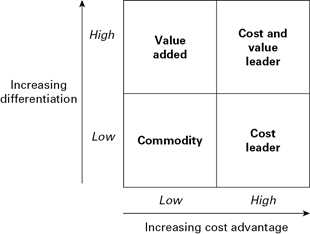

Michael Porter (1980, 1985) was one of the first commentators to highlight the need for organizations to understand that competitive success could only come through cost leadership or through offering clearly differentiated products or services. The basic model is illustrated in . Porters argument was that a company with higher costs and no differential advantage in the eyes of the customer was in effect a commodity supplier with little hope of long-term success unless it could find a way out of the box. His prescription was that the organization should seek to become either a low-cost producer or a differentiated supplier .

Figure 1.1 The competitive options

However, in reality it is not sufficient to compete only on the basis of being the lowest-cost supplier. The implication of this is that a competitor in the bottom right-hand corner has to compete on price if a company is only a cost leader, how else can it compete? Competing solely in terms of price will merely reinforce the customers view that the product is a commodity the very thing the company wishes to avoid. On the other hand, a strategy based upon differentiation will make it possible to compete on grounds other than price. While value for money will always be an issue, the aim is to increase customers perception of the value they are receiving and hence their willingness to pay a higher price.

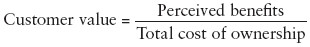

Organizations create value for their customers either by increasing the level of benefit they deliver or by reducing the customers costs. In fact customer value can be defined as follows:

Perceived benefits include the tangible, product-related aspects as well as the less tangible, service-related elements of the relationship.

The key point to note is that these benefits are essentially perceptual and that they will differ by customer. The total cost of ownership reflects all the costs associated with the relationship, not just the price of the product. Hence the customers cost of carrying inventory, ordering costs and other transactions costs all form part of this total cost concept.

Because logistics management, perhaps uniquely, can impact upon both the numerator and the denominator of the customer value equation, it can provide a powerful means of enhancing customer value.

An argument that is being heard more frequently is that logistics is a core capability that enables the firm to gain and maintain competitive advantage. More and more the view is expressed (Stalk, Evans and Shulman, 1992) that it is through capabilities that organizations compete. These capabilities include such processes as new product development, order fulfilment, marketing planning and information systems. There can be little doubt that companies that in the past were able to rely upon product superiority to attain market leadership can no longer do so, as competitive pressure brings increasing technological convergence. Instead these companies must seek to develop systems that enable them to respond more rapidly to customer requirements at ever lower costs.

Logistics management is essentially an integrative process that seeks to optimize the flows of materials and supplies through the organization and its operations to the customer. It is essentially a planning process and an information-based activity. Requirements from the marketplace are translated into production requirements and then into materials requirements through this planning process.

It is now being recognized that, for the real benefits of the logistics concept to be realized, there is a need to extend the logic of logistics upstream to suppliers and downstream to final customers. This is the concept of supply chain management .

Supply chain management is a fundamentally different philosophy of business organization and is based upon the idea of partnership in the marketing channel and a high degree of linkage between entities in that channel. Traditional models of business organization were based upon the notion that the interests of individual firms are best served by maximizing their revenues and minimizing their costs. If these goals were achieved by disadvantaging another entity in the channel, then that was the way it was. Under the supply chain management model the goal is to maximize profit through enhanced competitiveness in the final market a competitiveness that is achieved by a lower cost to serve, achieved in the shortest time-frame possible. Such goals are only attainable if the supply chain as a whole is closely coordinated in order that total channel inventory is minimized, bottlenecks are eliminated, time-frames compressed and quality problems eliminated.

This new model of competition suggests that individual companies compete not as company against company, but rather as supply chain against supply chain. Thus the successful companies will be those whose supply chains are more cost-effective than those of their competitors.

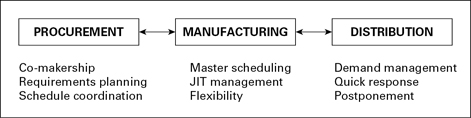

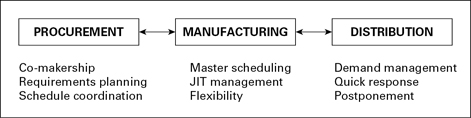

What are the basic requirements for successful supply chain management? outlines the critical linkages that connect the marketplace to the supply chain.

Figure 1.2 Critical linkages in the supply chain

The key linkages are between procurement and manufacturing, and between manufacturing and distribution. Each of these three activities, while part of a continuous process, has a number of critical elements.

Typically in the past, supply management has been paid scant attention in many companies. Even though the costs of purchases for most businesses are the largest single cost, procurement has not been seen as a strategic task. That view is now changing, as the realization grows that not only are costs dramatically impacted by procurement decisions and procedures but also that innovation and response-to-market capability are profoundly affected by supplier relationships.

The philosophy of co-makership is based upon the idea of a mutually beneficial relationship between supplier and buyer, instead of the more traditional adversarial stance that is so often encountered. With this partnership approach, companies will identify opportunities for taking costs out of the supply chain instead of simply pushing them upstream or downstream. Paperwork can be eliminated, problems jointly solved, quality improved and information shared. By its very nature, co-makership will often involve longer-term relationships, but with fewer suppliers.

Next page