1.1 Motivation

There has been a steadily increasing emphasis on enhanced quality of machined workpieces while at the same time reducing the cost per piece. Accompanying this is the decreasing size and increasing complexity of workpieces. This has put continual pressure on improvements in the machining process in terms of new processes, new tooling and tool materials, and new machine tools. Fundamental to this continual improvement is understanding edge finishing of machined components, especially burrs. Deburring, like inspection, is a non-productive operation and, as such, should be eliminated or minimized to the greatest extent possible.

An understanding of the fundamentals of burr formation leads us to procedures for preventing or, at least, minimizing, burr formation. This depends on analytical models of burr formation, studies of tool/workpiece interaction for understanding the creation of burrs and, specially, the material influence, data bases describing cutting conditions for optimal edge quality, and design rules for burr prevention as well as standard terminology for describing edge features and burrs. Ultimately, engineering software tools must be available so that design and manufacturing engineers can use this knowledge interactively in their tasks to yield a mechanical part whose design and production is optimized for burr prevention along with the other critical specifications. A review of the background to burr control is given first.

1.2 Introduction and Background

Burrs in machined workpieces are complex and troublesome problems. They require additional finishing operations (deburring) and complicate assembly as well as risk damage to the part. Handling parts with burrs is a challenge for workers. In a perfect world wed like to avoid, or at least minimize, burrs by careful choice of tools, machining parameters and tool path or work material and part design. The fact is that most burrs can be prevented or minimized with process control. Research and interest has been focused on problems associated with generation of burrs from machining for sometime but the focus has traditionally been on deburring processes. Understanding the burr formation process is critical to burr prevention. The level of scientific knowledge on burr formation is just in the early stages of development, see Fig. ].

Fig. 1

State of knowledge in burr formation

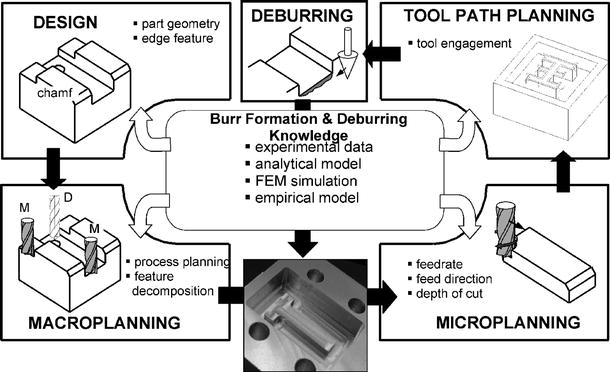

To effectively address burr prevention, the entire process chain from design to manufacturing must be considered, Fig.. Here we see the importance of integrating all the elements affecting burrs, from the part design, including material selection, to the machining process.

Fig. 2

Five level integration required for burr minimization, Dornfeld and Lee []

Burr formation affects workpiece accuracy and quality in several ways; dimensional distortion on part edge, challenges to assembly and handling caused by burrs in sensitive locations on the workpiece and damage done to the work subsurface from the deformation associated with burr formation. A typical burr formed on a metal component due to the exit of a cutting edge can range in shape and size from small and uniform (as in a knife burr) to rather large, nonuniform in shape and many millimeters in length. A number of things are clear from close inspection of burr images. There is substantial subsurface damage and deformation associated with a burr, the shape is quite complex and, hence, the description of a burr can be quite complex, and the presence of a burr can cause problems in manufacturing. More recently the problem of burrs and other machining and manufacturing related debris causing problems in the smooth functioning of precision mechanical devices has been addressed by a number of researchers. This just adds additional importance to the understanding of burr formations.

In fact, the range of burrs found in machining practice is quite wide, specially when the full range of processes from drilling to grinding is considered. To emphasize the point, Fig. shows typical drilling burrs and their classification in stainless steel as an indication of the potential variation. Burrs in milling and turning exhibit wide variation as well.

Fig. 3

Three typical burrs in drilling stainless steel, Dornfeld and Lee []

The costs associated with removing these burrs is substantial. The typical cost as a percentage of manufacturing cost varies up to 30% for high precision components such as aircraft engines, etc. In automotive components, the total amount of deburring cost for a part of medium complexity is in the range of 1520% of manufacturing expenses. Industrial practice has shown that the actual investment in deburring systems increases with part complexity and precision.

A better strategy is to attempt to prevent of minimize, or prevent, burrs from occurring in the first place. This has two immediate benefits in that, first, it eliminates the additional cost of deburring the component and the likelihood of damage during the deburring process and, second, in the case burrs cannot be eliminated it improves the effectiveness of any deburring strategy due to reduced and more standard burr size and shape. This requires a comprehensive approach to burr prevention and minimization consisting of a number of components.

To minimize or prevent burr formation requires that all stages of manufacturing from the design of the component through process planning and production be integrated so that the potential part features and material constraints, tooling and process sequences and process variables be considered from a perspective of the potential for creation of burrs on the workpiece, as seen in Fig.. This is not generally the case.

The successful implementation of integrated burr control methodologies is necessary to overcome the limitations of burr issues in machining. The future development of comprehensive integrated strategies for burr minimization and prevention will depend on: