Woodturning For Beginners Handbook

Everything You Need To Know About Woodturning

Copyright 2020

All rights reserved.

DEDICATION

The author and publisher have provided this e-book to you for your personal use only. You may not make this e-book publicly available in any way. Copyright infringement is against the law. If you believe the copy of this e-book you are reading infringes on the author's copyright, please notify the publisher at: https://us.macmillan.com/piracy

Contents

Woodturning technique

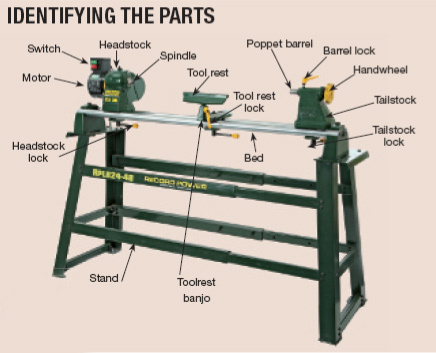

Its a bit obvious, but the fi rst thing a woodturner needs is a lathe. Its actually the worlds oldest power tool see the panel (left) for a bit of history. As you begin to investigate whats available, youll soon discover that theres a bewildering choice of models, with very different specifi cations and prices, and its very easy to become confused about exactly what you require. If this is your situation and you need some help, then this feature highlights the main factors you need to consider before you buy.

The lathe today

Woodturning has progressed enormously in recent years and is now no longer just a means of producing functional items, but is fast approaching the status of an art form. To fuel this massive increase in popularity and demand, many woodworking machinery manufacturers have hurriedly added lathes to their range, but a good machine requires a number of essential features that are often overlooked in the rush to get new equipment onto the market.

Cheap and cheerful

There are lots of very cheap lathes on the market that all look the same and appear to give you a lot for your money, photo 1. These machines are very much entry-level models, being suffi cient to get you started, but if you progress much beyond very basic work you will soon fi nd them very limited. Some even come with a stand and incorporate variable speed, but there is a defi nite correlation here between the price you pay and the quality you get.

Weight is good

As a general rule, the heavier and more substantial the machine, the better. Vibration is the woodturners worst enemy, particularly if the workpiece is long or out of balance, and there is nothing to beat sheer weight to minimise this vibration.

For this reason, its better to buy a lathe that is cast rather than fabricated, but this inevitably often involves greater cost. However, do remember that unlike a lot of other machines, you will often spend hours working at the lathe. Consequently it needs to be as smooth and quiet in operation as possible, so always think carefully about the quality and buy the best you can afford.

Photo 1. Cheap lathes appear t o give you a lot for your money

Photo 2. You need a distanc e between centres of at least 30in

Photo 3. and a swing of at leas t 9in between spindle and bed

Bed and swing

When you are buying a lathe, there are two capacities you need to consider. The distance between centres determines the maximum length of workpiece you can turn. For general work you will need at least 30in, and preferably 36in, photo 2. Incidentally, lathe dimensions are still mainly given in imperial measurements; for metric buffs the equivalents are 760 and 915mm. Longer beds are available, and whilst these may appear attractive, they can add to any vibration problems unless theyre properly braced, so this is one instance where it is better not to buy too much capacity unless you have the specific need for it.

Another useful measurement of size is the swing of the lathe, photo 3. This is the height of the main spindle above the bed and therefore determines the maximum diameter of work you can turn, unless the head rotates round. For anything remotely approaching serious work, you need a swing of at least 9in (230mm), but in practice the bigger the better.

Bench or floor mounted?

A professional turner will probably need a heavy-duty floor-standing lathe, but for the home woodturning enthusiast a bench-mounted model will probably be quite sufficient, photo 4. These bolt down to any convenient work surface, but this must be really solid. The advantage of mounting it on your own workbench is that you can get the centre height just right a serious consideration if you anticipate doing a lot of turning in the future.

Photo 4. A bench-mounted mode l like this will suit most woodturning beginners

Stands and storage

Several manufacturers provide leg-stands as an optional extra if you dont want to build a bench. These stands vary from a rather crude folded steel or tube arrangement, to a more rigid affair with provision for a tool shelf, photo 5. Bear in mind that the performance of your lathe depends on how well it is mounted, so buy a leg-stand only if it looks man enough for the job.

Photo 5. Some more rigid leg-stand s include provision for a tool shelf

Photo 6. Under-bench storage help s to give a stand useful extra mass

A homemade wooden bench is often better at absorbing vibration than a crude metal stand, and it can change the whole operation of the lathe. If you are short of space in the workshop, you can build in a lot of storage for tools or raw materials under the lathe, which also helps to give the structure a bit more mass, photo 6.

The lathe bed

The bed is made from either heavy metal bars or tubes, photo 7, but some machines still feature a flat cast bed. This may be quite crude on the cheaper machines, or a work of art on top-of the-range models, photo 8.

Whatever the construction, it must be strong enough to support both the tailstock and the tool-rest without any flexing, and allow free and easy movement of them both. It must also permit shavings to fall through unobstructed and should sit well clear of the bench, so you can slide the tools underneath it without banging the sharpened edges.

Photo 7. The lathe bed is mad e from heavy metal bars or tubes