Lecture Notes in Production Engineering

Series Editors

Bernd-Arno Behrens

Leibniz Universitaet Hannover, Garbsen, Niedersachsen, Germany

Wit Grzesik

Opole, Poland

Steffen Ihlenfeldt

Institut fr Werkzeugmaschinen und, TU Dresden, Dresden, Germany

Sami Kara

Mechanical & Manufacturing Engg, University of New South Wales, Sydney, NSW, Australia

Soh-Khim Ong

Mechanical Engineering, National University of Singapore, Singapore, Singapore

David Williams

Loughborough, UK

Lecture Notes in Production Engineering (LNPE) is a new book series that reports the latest research and developments in Production Engineering, comprising:

LNPE publishes authored conference proceedings, contributed volumes and authored monographs that present cutting-edge research information as well as new perspectives on classical fields, while maintaining Springer's high standards of excellence. Also considered for publication are lecture notes and other related material of exceptionally high quality and interest. The subject matter should be original and timely, reporting the latest research and developments in all areas of production engineering. The target audience of LNPE consists of advanced level students, researchers, as well as industry professionals working at the forefront of their fields. Much like Springer's other Lecture Notes series, LNPE will be distributed through Springers print and electronic publishing channels. To submit a proposal or request further information please contact Anthony Doyle, Publishing Editor (anthony.doyle@springer.com).

More information about this series at https://link.springer.com/bookseries/10642

Christian Brecher and Manfred Weck

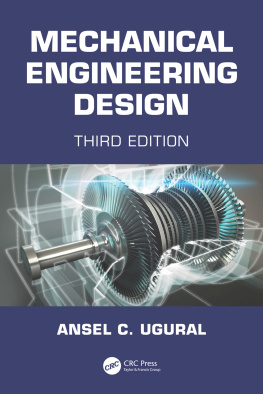

Machine Tools Production Systems 2

Design, Calculation and Metrological Assessment

1st ed. 2021

Logo of the publisher

Christian Brecher

Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, Aachen, Germany

Manfred Weck

Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, Aachen, Germany

ISSN 2194-0525 e-ISSN 2194-0533

Lecture Notes in Production Engineering

ISBN 978-3-662-60862-3 e-ISBN 978-3-662-60863-0

https://doi.org/10.1007/978-3-662-60863-0

Springer-Verlag GmbH Germany, part of Springer Nature 2021

This work is subject to copyright. All rights are reserved by the Publisher, whether the whole or part of the material is concerned, specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed.

The use of general descriptive names, registered names, trademarks, service marks, etc. in this publication does not imply, even in the absence of a specific statement, that such names are exempt from the relevant protective laws and regulations and therefore free for general use.

The publisher, the authors and the editors are safe to assume that the advice and information in this book are believed to be true and accurate at the date of publication. Neither the publisher nor the authors or the editors give a warranty, expressed or implied, with respect to the material contained herein or for any errors or omissions that may have been made. The publisher remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Responsible Editor: Thomas Zipsner

This Springer imprint is published by the registered company Springer-Verlag GmbH, DE part of Springer Nature.

The registered company address is: Heidelberger Platz 3, 14197 Berlin, Germany

Foreword for the Machine Tools and Manufacturing Systems Compendium

Machine tools are among the most important means of production in the metalworking industry. The current high standard of living in industrialized nations would be inconceivable had this category of machinery not been developed. The Federal Republic of Germany is a world leader in the production of machine tools. In the Federal Republic of Germany, approximately 7.4% of the total mechanical engineering production volume comes from the machine tool industry and 7.0% of those employed in mechanical engineering work in the machine tool industry (German Machine Tool Builder's Association (VDW), as of 2018).

The application areas for machine tools are just as diverse as their structural design and degree of automation. According to the technological processes, this extensive field ranges from machine tools for primary forming and forming, through machine tools for cutting (including chip-removing machine tools) to joining machines. These machines have varying degrees of automation and more or less flexibility depending on the workpieces to be machined and the lot sizes. As a result, single-purpose and special machine tools as well as universal machines with an extensive range of potential applications are available on the market.

Due to the increasing demands on performance and accuracy, the designer of these machines must ensure an optimum design of the individual machine components. To do this, the designer must have a comprehensive knowledge of the relationships between the physical properties of the components and of the machine elements. Today, the designer can provide computer-aided designs using a substantial library of programs. The criteria that determine performance and accuracy such as the geometric, kinematic, static, dynamic, thermoelastic and acoustic properties can be evaluated through metrological analyses and objective assessment methods. The specific improvements necessary can then be put in place.

The continuing tendency toward the automation of machine tools has led to a broad spectrum of control system alternatives. In recent years, developments in electrical engineering, electronics and software technology have had a significant influence on machine control systems. Microprocessors and process computers can now provide control-engineering solutions that were previously unthinkable. The mechanization and automation efforts have also included the areas of material transport and machine feeding. Considerations in this area led to transfer lines in mass production and to flexible manufacturing cells and systems in small and medium series manufacturing.

The three volumes that make up this series on the subject of Machine Tools and Manufacturing Systems are aimed at both university students majoring in production engineering and all practicing professionals who must keep pace with the increasingly complex material covering this branch of mechanical engineering. In addition, these volumes will help the user select suitable machines and the relevant control systems. The machine manufacturer is provided with ways of producing the best layout of the machine components, drive systems and control systems together with options for specific improvements based on metrological analyses and objective assessment methods.