Start TO Finish

Sports

Gear

FROM

P lastic

TO

Soccer B all

ROBIN NELSON

Copyright 2015 by Lerner Publishing Group, Inc.

All rights reserved. International copyright secured. No

part of this book may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means

electronic, mechanical, photocopying, recording, or

otherwisewithout the prior written permission of Lerner

Publishing Group, Inc., except for the inclusion of brief

quotations in an acknowledged review.

Lerner Publications Company

A division of Lerner Publishing Group, Inc.

241 First Avenue North

Minneapolis, MN 55401 USA

For reading levels and more information, look up this title

at www.lernerbooks.com.

Library of Congress Cataloging-in-Publication Data

Cataloging-in-Publication Data for From Plastic to Soccer

Ball is on file at the Library of Congress.

ISBN: 9781467738897 (LB)

ISBN: 9781467747431 (EB)

Manufactured in the United States of America

1 CG 7/15/14

TABLE OF Contents

I love playing soccer. How is a soccer ball made?

First, cloth is glued to the cover.

The outside cover of a soccer ball is made of plastic.

The plastic keeps water from getting inside the ball.

Up to four layers of cloth are glued to the plastic to

make it strong. The layers help the ball keep its shape.

Next, a machine cuts the panels.

A machine cuts the cover into shaped pieces. The

cutting machine also punches holes around the

edges of each panel. These holes are for stitching

the panels together.

The panels are printed.

A machine or a worker prints logos and

other designs on the panels. A special

fast- drying paint is used.

Then the panels are stitched together.

The soccer ball is put together inside out. Before the worker

stitches the last panels, he or she turns the ball right side out.

That way, the stitches cant be seen. It takes between one

and three hours for a worker to stitch one soccer ball.

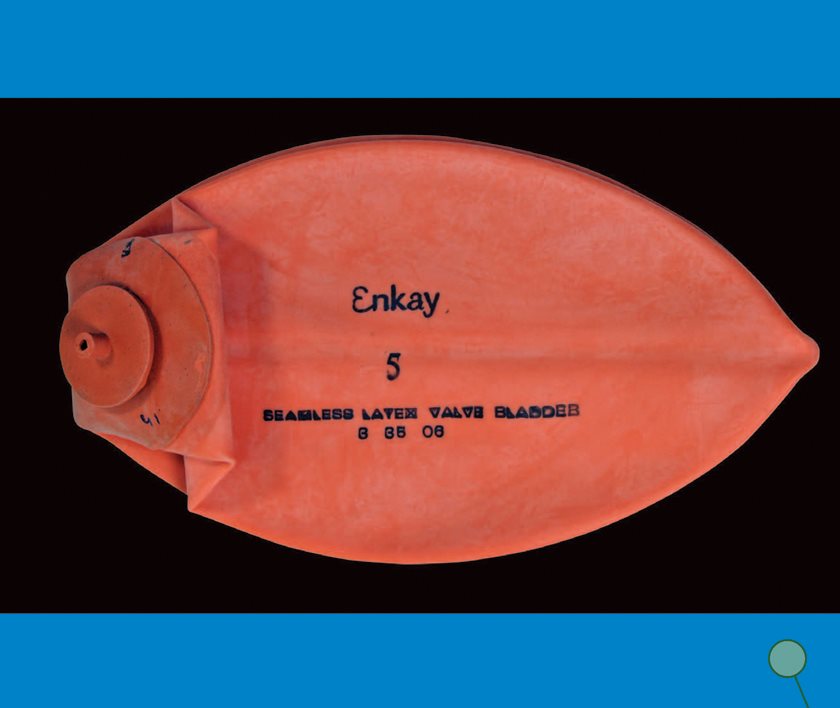

The bladder is made.

The bladder holds the air inside a soccer

ball. Rubber is heated and put in a mold.

The rubber forms a balloon. Then it cools.

A valve is added to the bladder.

A valve is attached to the bladder. The valve lets

air into the ball but keeps it from leaking out.

Next, a worker adds the bladder.

A worker tucks the bladder inside the cover. The

valve is glued behind a small hole in the cover.

Then the last panels are stitched together.

Air is pumped into the ball.

Air is pumped into the soccer ball through the

valve. Air is added until the ball is round and firm.

Then a worker checks the ball for air leaks. He or

she makes sure it is the right size and weight.

Finally, the soccer ball is shipped.

The finished soccer ball is put in a box. Then it is

sent to a store. The soccer ball is ready to kick!

Glossary

bladder: a balloon-like, air-filled bag

inside a ball

cloth: material made by weaving threads

together

logos: symbols used to identify a company

panels: pieces of material that are part of

a larger surface

plastic: a light, strong substance that can

easily be made into different shapes

valve: a device that controls the flow of

air in and out of a ball

Further Information

Brown, Monica. Pel, King of Soccer/Pel, El rey del ftbol . New York: Rayo,

2009. Read the true life storyin English and Spanishof Pel, the first man

in the history of soccer to score a thousand goals and become a legend.

The Life Cycle of a Soccer Ball

http://www.epa.gov/osw/education/pdfs/life-soccer.pdf