CarTech

CarTech, Inc.

39966 Grand Avenue

North Branch, MN 55056

Phone: 651-277-1200 or 800-551-4754

Fax: 651-277-1203

www.cartechbooks.com

2013 by Joseph Palazzolo

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without prior permission from the Publisher. All text, photographs, and artwork are the property of the Author unless otherwise noted or credited.

The information in this work is true and complete to the best of our knowledge. However, all information is presented without any guarantee on the part of the Author or Publisher, who also disclaim any liability incurred in connection with the use of the information and any implied warranties of merchantability or fitness for a particular purpose. Readers are responsible for taking suitable and appropriate safety measures when performing any of the operations or activities described in this work.

All trademarks, trade names, model names and numbers, and other product designations referred to herein are the property of their respective owners and are used solely for identification purposes. This work is a publication of CarTech, Inc., and has not been licensed, approved, sponsored, or endorsed by any other person or entity. The publisher is not associated with any product, service, or vendor mentioned in this book, and does not endorse the products or services of any vendor mentioned in this book.

Edit by Paul Johnson

Layout by Monica Seiberlich

ISBN 978-1-61325-127-0

Item No. SA289

Library of Congress Cataloging-in-Publication Data

Palazzolo, Joseph.

Ford differentials : how to rebuild the 8.8 and 9 inch / By Joseph Palazzolo.

p. cm.

1. Ford automobile--Differentials--Maintenance and repair--Handbooks, manuals, etc. 2. Ford automobile--Axles--Maintenance and repair--Handbooks, manuals, etc. I. Title.

TL215.F7P35 2013

629.245--dc23

2012045860

10 9 8 7 6 5 4 3 2 1

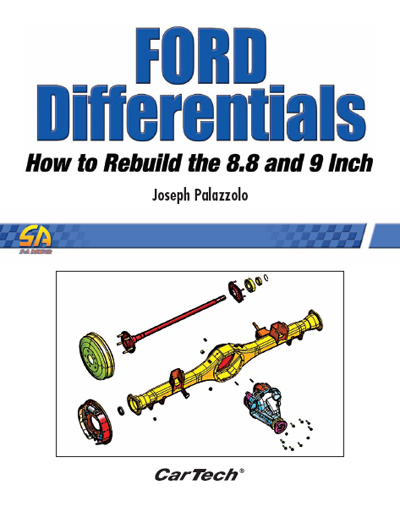

Title Page: An assortment of Ford 9-inch axle stampings is welded together to create the housing. The cast-iron third member is installed through the front of the housing. It supports all of the gear and bearings, which allows for easier gear ratio swaps, if you have multiple third members.

Back Cover Photos

Top Left: You need to carefully identify and inspect the differential when youre in the market to buy one. This case looks like a nodular unit from the front, regarding rib structure, but does not have the N on it. When you look on the inside, you see the WAB-4025A. This is not a nodular unit.

Top Right: The 8.8-inch pinion requires some shimming to set the correct pinion depth on the ring gear. Some aftermarket gears are marked; Ford Motorsports gears and original-equipment gears are not marked. In this case, the pinion head markings identify it.

Middle Left: A dial indicator is set up to verify backlash and pattern. Remember to check backlash in at least four different positions; there should not be more than .004-inch variation. Every new gear set should come with a backlash recommendation in the instructions.

Middle Right: The side gears have been installed. Once in place, the washer is set in position and assembly grease is applied to the face of the washer. When all of the differential internal pieces are in place the differential case halves can be closed.

Bottom Left: The ring gear is pulled into position and a couple of bolts are installed. Note the bolts have washers under the heads. These smaller headed bolts with washers are used in Traction-Lok applications only. Open differentials and most other aftermarket differentials use larger headed open differential style ring gear bolts.

Bottom Right: This Ford 9-inch differential assembly is nearly complete. The adjuster nuts need to be set in place. Extra care must be taken to be sure the threads are lined up correctly.

OVERSEAS DISTRIBUTION BY:

PGUK

63 Hatton Garden

London EC1N 8LE, England

Phone: 020 7061 1980 Fax: 020 7242 3725

Renniks Publications Ltd.

3/37-39 Green Street

Banksmeadow, NSW 2109, Australia

Phone: 2 9695 7055 Fax: 2 9695 7355

CONTENTS

This project has been a very challenging journey for me. Even though the 1957 Chevy highlighted in is not my first car restoration, it proved to be frustrating at times to be writing while building a car. I sincerely thank everyone who helped either directly or indirectly with the writing of this book. With this text completed, hopefully now I can get the car completed.

First and foremost, I must thank my wife, Kathy, for persevering through yet another book project while juggling the demands of the household and our twin boys. It has proven to be quite a challenge for both of us. I am truly blessed to have such a kind woman in my life supporting this endeavor and me. You never reminded me how difficult this was on all of us and instead you offered support and continuous encouragement, even when I questioned why I was doing this again. This book has become a family affair that is not just my book but rather our book. Thank you.

The entire team at Currie Enterprises, specifically Brian Shephard, treated me like part of the extended family and opened up the entire shop, parts, and mechanics for this project. Without their knowledge and willingness to share, this book would have never been possible. There was never a time when they did not accommodate any of my many requests for support and help. The Currie team recognized the need for a Ford axle book and even helped push this book to hopefully be considered the ultimate reference.

I thank Earle Williams for all of the great support, producing truly awesome hardware, and even the shop tour and guidance on the car. It is people like Earle that make the performance and aftermarket industry great.

My good friend Tony Nausieda reviewed the text countless times for accuracy while working on his advanced degree. I am fortunate to have a friend who is willing to sacrifice sleep and his own projects to help out with this text.

Next page