WORK SHOP AND TOOLS

THE FARMERS WORKSHOP

T HERE is no doubt that of all the handy farm devices good tools head the list. So, in this book, we are going to start with carpenter tools and the place to keep and use them. Every farmer ought to have a workshop in which he can do odd jobs and make things when the weather prevents out-of-door work, or at times when there is little to do on the form. Economy and thrift demand that a farmer should have and keep in good condition a few essential carpenter tools. First of all he should have a long, strong, smooth-top bench and, either on racks above the bench or in a tool chest, he should keep in order, and where he can easily find them when wanted, his stock of carpenter tools. Some of the tools that will be found useful are the following:

A rip saw, a crosscut saw, a back saw, and a compass saw; a jack plane, a fore plane, and a smoothing plane; a shave or drawing knife; two or three chisels of different sizes for woodworking and a cold chisel for metal; a gouge or two; a good hatchet; two or three hammers, including a tack hammer and a bell-faced claw hammer; a brace or bit stock with a set of half a dozen or more bits of different sizes; one or more gimlets; a mallet; a nail set, a large screw driver and a small one; a gauge; a spirit level; a miter box; a good carpenters squareNo. 100 is a good standard size; compasses or dividers; cut nippers, a pair of small pincers and a pair of large ones; a rasp; a large, flat file; at least one medium-sized three-cornered file and a half-round file.

It is poor economy to buy cheap tools. Of course extravagance is to be avoided, but be sure that you get first-class material in every tool you buy. It is a good plan to get a good practical carpenter to assist you in selecting your tools. Keep on hand in the shop a variety of nails, brads and tacks, screws, rivets, bolts, washers and nuts, and such small articles of builders hardware that are likely to be needed occasionally, including hinges, hasps and staples and some sand-paper. Have a good plumb line, chalk and pencils. Keep in a handy place a jar of a good liquid glue, and some cement. See to it that the shop contains a good stock of well-seasoned lumber, both hard wood and soft.

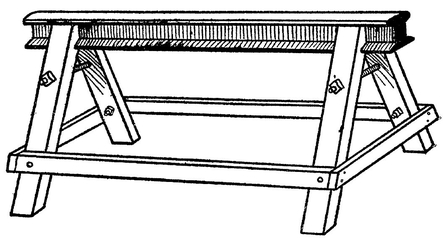

Attached to the bench should be a bench screw or vise. This need not be an expensive one, but should be of good size and strong. There should also be a pair of carpenters saw benches, a shaving horse, a small anvil and a grindstone. Every farmer has a grindstone somewhere about the buildings, but it is a great convenience to have a good one in the workshop.

A corner of the shop should be devoted to painting supplies, including several colors of good standard ready-mixed paints and stains, raw linseed oil, boiled linseed oil, turpentine, varnish, putty, points for setting glass, several brushes of different sizes, a good putty knife and panes of glass of different sizes ready for emergency.

A farmer ought to be able to do occasional little jobs of soldering. He needs soldering iron, a bar of solder, resin, a little bottle of soldering fluid, which can be purchased already prepared, also a small sheet-iron furnace in which to heat the soldering iron.

It would cost quite a tidy sum to buy all these things at once, but they can be gradually accumulated as one is able to purchase them, and then the outfit should be kept complete. Whenever anything in the shop is broken, worn out, or disappears it should be replaced.

Whenever farm implements or anything about the barn or house are broken or out of order, they should be properly fixed. Often a few minutes spent at the right time will make a thing almost as good as new, while, if neglected, it may soon get beyond repair and have to be thrown away. A thrifty farmer always keeps his farm implements well housed and in repair. It is not what we earn, but what we save, that makes us rich. It is quite as important to stop the leaks as it is to figure on big profits directly.

RUNNING THE GRINDSTONE

If the face of the grindstone is hard and glazed pour a little sand on the stone every few minutes until the glaze is worn off and the stone will cut like a new one. This condition is caused by exposing the stone to the weather. It is best to keep the stone in a shed under cover, but if this is not possible, set it under a tree and put a box over it when not in use. It is surprising how easy a little oil on the bearings will make the stone run. A few drops of kerosene will cut the gum if it runs hard and then some oil or axle grease will make it go easy.

It is hard to stand on one foot and work the treadle with the other. The job can be made easy by bolting two boards to the grindstone frame, and extending it 2 feet, on which place a seat as shown in the cut. An uneven stone needs to be cut down and toned up. This can be done by grinding against the end of a piece of pipe, having the stone dry.

Good nature is as contagious as the measles. Put on your best smile when you get up in the morning and observe how everybody will greet you with a sunny face.

A HOMEMADE ANVIL

A homemade anvil can be constructed from a 4-foot piece of railroad rail mounted on a trestle, as shown in the sketch. This affair will stand a lot of heavy pounding, and comes in handy in many ways. The rail is just about the right shape to make an anvil.

MAKIN A NEW TOOL

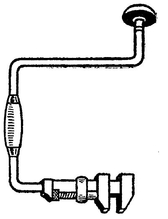

A very handy wrench for many kinds of work, such as making gates and contrivances, where small bolts are used, is shown in the cut. From a small monkey wrench remove the wooden handle, and weld the metal part to an old bit-stock, as shown in the cut. This permits of very rapid work in screwing up small bolts. Where there are so many things to do as there are on a farm, it pays to do things in the easiest and quickest BIT-STOCK WRENCH way. This is one of the real time-savers.

Learn to live, and live to learn,

Ignorance like a fire doth burn,

Little tasks make large return.Bayard Taylore.

HOW TO MAKE A SHAVING HORSE

One of the most useful devices on a farm is a shaving horse. Make a bench 18 feet high of a good 2-inch plank, c, level off the edges so that it will make a comfortable seat. Upon this place a slanting platform, b, through which is cut a hole in which the clamp, a, works.

The clamp must be made of heavy hard wood that is tough and will not split. The shank, f, must be an extension of the clamp, a. Several holes in the plank will allow the clamp to be raised so as to take in larger pieces of wood. The treadle, g, is kept in place by a peg at h. To operate this horse the workman places his foot upon the treadle, inserts the wood to be clamped under the edge of a, and pushes backward upon the treadle. This clamps the wood and the drawing knife can be used readily and much more rapidly than with a vise.