2013 by Norman Ahlhelm

No part of this book may be reproduced in any form or transmitted by any means without the writtenpermission of the author.

No patent liability is assumed with respect to the use of the information contained herein. Everyprecaution has been taken in the preparation of this book. The publisher and author assume noresponsibility for errors or omissions. Neither is any liability assumed for damage resulting from the useof the information contained herein.

Introduction

This book is an introduction to the techniques of electronic repair and, to a lesser extent,fabrication. Electronic repair in this text is directed only at soldering and board repair, nottroubleshooting. And, as with all texts dealing with technology, the book is not inclusive of everymethod available to the technician. No prior knowledge of the operation of electronic components orrepair expertise is needed. Basic soldering tools are used as much as possible to perform the work.Unfortunately, some specialized tools will have to be used for board repairs and the installation ofsurface mount components.

This edition has minor changes to include: metric wire gages, standards are now listed in metricalso, improved some images, and revision of a few confusing questions.

The standard used throughout the text for all soldering is IPC (Association ConnectingElectronics Industries, formerly the Institute of Interconnecting and Packaging Electronic Circuits) J-STD001D dated February 2005. It is the accepted model used by the American National Standards Instituteas well as the Department of Defense. Repair standards should meet IPC-7711/7721.

Safety

Listed here are some of the safety precautions that should be observed at all times.Additionally, follow the procedures established by Federal and State regulations and your employer.

1) Know your tools and supplies.

2) Inspect your tools to make sure they are in perfect working order.

3) Wear eye or face protection.

4) Work in a well-ventilated area and/or have fume extraction devices operating if available.

5) Wash your hands after working with solder, particularly those containing lead.

6) Avoid wearing loose jewelry or clothing ties are out!

7) Wear long sleeves and pants this prevents burns if solder should splatter.

8) No open toed shoes same reason as six. You may also be working with heavy objects.

9) Do not touch the irons tip even if you think it is cold.

10) Keep your work area clean and organized.

11) Make sure the iron never touches the power cord.

12) Ergonomics must be considered. Make sure the chair is in the correct position, the work

table is at a proper height, and lighting is sufficient.

13) Solder on fire resistant surfaces.

14) Do not overload your electrical outlets.

15) Shut your equipment down when not in use.

Table of Contents

Chapter 1, The Basics.

Wire Gage .7

Other Conductors

Waveguides ..13

Chapter 2, Standards: Wires and Splices

Wire Connections

Crimping and Splicing Tools ....26

Solder Splicing Sleeves.....28

Coaxial Cable Connectors ..28

Chapter 3, Irons, Solders, and Fluxes

Mass, Time, and Pressure

Chapter 4, Wire Connections and Connectors

Tinning ....57

Soldering Wires Splices

Sealing the Tap Splice...73

Chapter 5, Printed Circuit Boards

Boards types ......76

Making a Circuit

Chapter 6, Installation and Removal of

Through-Hole Components

Before Component Installation

Mounting an Unsupported

Through-Hole Component ....96

Through-Hole Component Removal

Conformal Coatings..........103

Chapter 7, Removal and Installation of

Surface Mount Components

Installation and removal of Chip Resistors, MELFs,

Chip Capacitors and SOTs

Installation of QFPs, PLCCs, and SOICs

Re-Balling Using Solder Paste130

Re-Balling Using Solder Spheres ...131

Chapter 8, Track, Pad, and Board Repairs

Damaged or Missing Tracks

Lifted Pads and Tracks .....134Broken or Missing Tracks

Using a Track Frame without Adhesive ..134

Using a Track Frame with Adhesive ..140

Busbars ....142

Staples ...143

Jumper Wires.144

Replacing Large Sections of Damaged PCBs

Small Repairs (1/2 or Less): Repair Does

Damage Extends Through the Board.151

Replacement of Large Sections of a PCB ..152

Chapter OneThe Basics

A wire must be electrically transparent to the circuit in which it functions. By electrically transparent wemean that it must not affect the current or voltage of the circuit. So, how can a wire affect current orvoltage in a poor design? How will a wire react to different frequencies? How does a wire function in a proper design? Finally, if you have to make a repair to a wire, how do you make it as mechanically strongas the original and make it electrically sound?

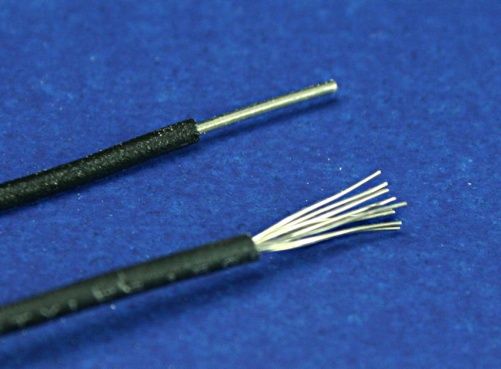

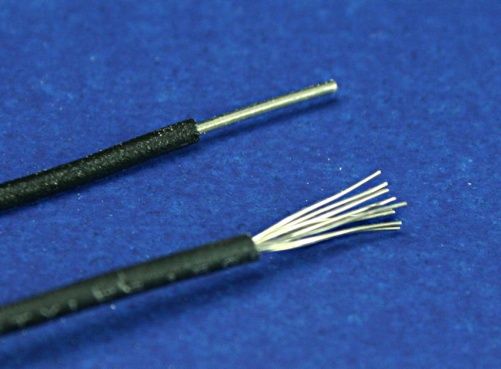

Figure 1-1

Figure 1-1Solid and Stranded wires.

Conductors

The most commonly used conductor is the wire. It comes intwo varieties, Stranded and Solid. The material from whichthey are usually made is copper (because of its very lowresistance and reasonable cost). Figure 1-1 shows both a solidconductor and a stranded conductor. Each type of wire hascertain benefits and shortcomings. The solid wire is easier tomanufacture, it is only a single strand. Its disadvantage is thatsolid wire is not intended to be used in areas where it must be

Conductance Compared toMaterialSilver

Silver

Copper

Gold

Aluminum

Iron

Tin

Carbon0.05

Table 1-1bent regularly. This wire may be bent only a few timesbefore it breaks. Stranded wire, on the other hand, ismore costly to manufacture: a certain number ofstrands of a given size must be wound together toachieve the desired diameter. It has the advantage ofbeing more resilient than a solid wire (of similar size)when wires must be bent. It can be flexed more often without damage.

Copper, as mentioned earlier, is an excellentconductor. The resistance of copper per foot isextremely low, less than 0.077 ohms for a wire havinga diameter of 0.012. This makes it largely transparent electrically since it does not affect current muchor create voltage drops. As the size of the wire increases, this resistance value continues to drop. Table1-1 shows the relative conductance of copper as compared to the idealmaterial, silver. Silver mightbe the best conductor available, but it is too costly for most consumer electronics. Gold is also listed.You can see that it has 78% of the conductance of silver. Aluminum is rarely, if ever, used in circuits.Because of its considerable resistance, heat tends to build up along its length. Aluminum wire was usedin residential electrical systems during the 1970s and was responsible for several home fires because ofits high resistance.

Wire Gauge

The diameter of a conductor has to be sized to the application, some circuits require morecurrent and voltage than others. In the United States, the American Wire Gauge (AWG) standard is usedas a measure of conductor diameter. Table 1-2 lists some of the common sizes used. Mostmanufacturers of electronics use the even numbered gauges so many of the odd number values havebeen omitted.

MetricDiameterArea inAWGWire3(mm2)in milscmils1OhmsFusePerMaximumRating1000 FtCurrent*s2

403.1459.8910.093.54312.555

383.96515.7210.1124.40919.44

365250.145.51230.379

346.30539.7530.187.08650.218

327.9563.2030.259.84296.872

3010.025100.50.3111.8139.236

Figure 1-1Solid and Stranded wires.

Figure 1-1Solid and Stranded wires.