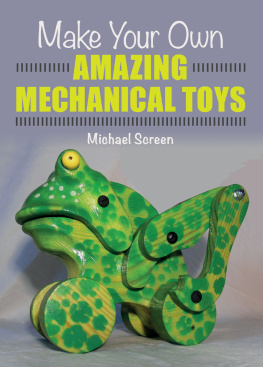

Michael Screen

THE CROWOOD PRESS

First published in 2018 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2018

Michael Screen 2018

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 512 1

Acknowledgements

I would like to give my sincerest thanks to my partner Isabelle for her invaluable help and encouragement in editing and preparing the text for submission. I would also like to thank her father Paul for his photography and exceptional Photoshop skills. Finally, I would like to thank the countless students, both young and old, who have unwittingly served as my toy-making guinea pigs over the years.

CONTENTS

INTRODUC TION

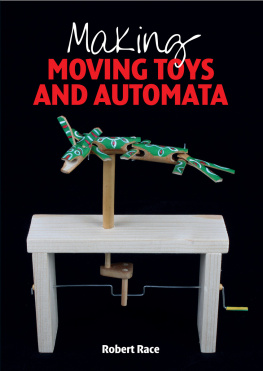

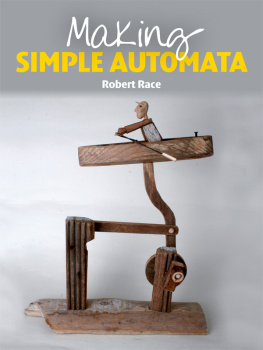

Are you looking to develop your ambition as a toy maker and craftsperson? You may be an aspirational hobbyist, semi-retired or retired, an educator, a practising craftsperson or a student looking for inspiration: this book shares some of my skills and experiences as an educator, toymaker and craftsperson of over thirty years.

What could be more satisfying than designing and building your own mechanical timber toys? They make amazing gifts both for children and for not-so-young family members. Your playthings will be given a name, and will be cherished, played with, and hopefully passed to a new generation. They will develop the endearing patination of age and use as they progress through their lifetime.

Perhaps you lack the confidence to currently develop your own mechanical toy ideas, or are looking for a challenge to produce more sophisticated examples. Mechanical toys are the perfect synthesis between craftsmanship, engineering and artistic expression. You have a plaything with its own beautiful mechanical action, and sounds that dont need batteries or mains electricity to make them function. It is always fascinating to watch the input motion being converted into walks, wiggles, shakes, snaps, rattles and rolls. People love to examine them, to try and unravel the mystery of what is essentially a simple piece of wooden engineering.

The toy maker has a considerable repertoire of techniques and materials at their disposal for generating movement and character in a plaything. Many materials and processes are available, as even a glancing look at historical toy making will show. People have always used the indigenous materials and skills available to them, generating a rich and varied range of toys from different times across the world.

This book focuses on the production of five kinetic wheeled toys operated by a push-and-pull action, with timber as the primary construction material. They are not, strictly speaking, automata, which tend to be remotely operated with a more complex mechanism and generally operated by a hand-turned crank. The projects in this book use wheels, cams, cranks and linkages in various combinations to generate some beautiful mechanical actions when the toy is pushed and pulled.

Mechanical toys require only small amounts of material, such as offcuts and recycled timber, and can be produced in a relatively small space. You will also find in this book information on surface finishes, techniques and treatments to make your toys look amazing. This book will give you clear, concise, step-by-step instructions to produce five practical, kinetic toy projects, shown within these covers. Each chapter is filled with detailed step-by-step illustrated guidelines to produce a well made, functioning outcome. The book also contains advice and strategies to help you develop your own confidence and creativity. The only prerequisites to developing your toy making are access to rudimentary tools, and a workspace with a stable, secure worktop and vice.

Finally, timber toy craft production also offers an ethical and aesthetic antidote to the ruthless blandness and banality of many modern, massproduced, injection-moulded plastic toys.

CHAPTER ONE

TIMBERS AND MANUFACTURED BOARDS

Hardwoods and Softwoods

There is a bewildering range of timbers available to the craftsperson, each with its own unique physical and mechanical properties, which make it suited to any given application. Its tempting to launch into a dry, arid, academic description of timber as a construction material, but for the purposes of this book you need only know several basic facts. First, timbers are classified as either softwoods or hardwoods which can be confusing as some softwoods are hard, and conversely some hardwoods are soft.

The term hard and soft refers to whether the source of the timber is from a deciduous tree or a conifer, and isnt necessarily a description of an individual timbers physical properties. Hardwoods come from deciduous trees, which are slow-growing trees that lose their broad, papery leaves and become dormant in the winter months. Conifers are the evergreens with waxy, spiny, spiky leaves which do not lose their leaves and tend to grow much faster. Conifers are classed as softwoods, and include the pine, which is a broad, generic term for a number of different conifers. All trees produce an annual growth ring, which indicates the quantity of timber produced radially within the trunk during the growth season. Hardwoods tend to produce a narrow, denser growth ring than conifers.

Deciduous trees hardwoods include species such as oak, ash, elm and beech, and the tropical hardwoods such as Sapele, mahogany and teak. Largely because of their slow growth, the wood fibres that are produced in the seasonal growth rings are more compact, leading to a timber of greater density. The relatively rapid growth of conifers produces wider, more fibrous growth rings and less dense timber. Its worth remembering that balsa wood comes from a deciduous tree and is technically a hardwood even though its very soft. Conversely parana pine, which is very similar to a conifer, is very hard and durable.

Timbers Physical Properties

All timbers have their own characteristics, ranging from elasticity, durability, density and ease of working, to name but a few. Some timbers, such as oak and beech, are heavy, hard, dense and difficult to work; they blunt tools easily, but are very durable, meaning they withstand atmospheric corrosion and abrasion well. Some timbers, especially tropical hardwoods, contain their own water repellent and insecticide, making them difficult to glue and giving the occasional unfortunate machinist respiratory problems and a nasty skin rash.

Grain structure and direction also offer some of the key characteristics of timbers. For practical purposes, a straight, knot-free timber often offers the best working and construction properties. People have always prized the beautiful figuring and grain patterns of timbers, and sometimes appearance trumps practical considerations for the most attractive and enduring timber objects.

Next page