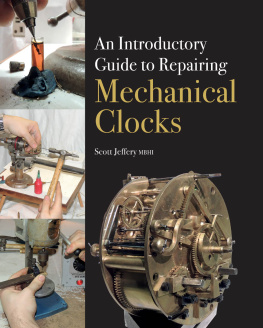

An Introductory

Guide to Repairing

Mechanical

Clocks

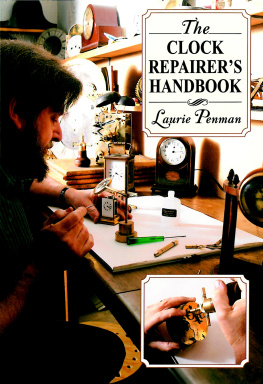

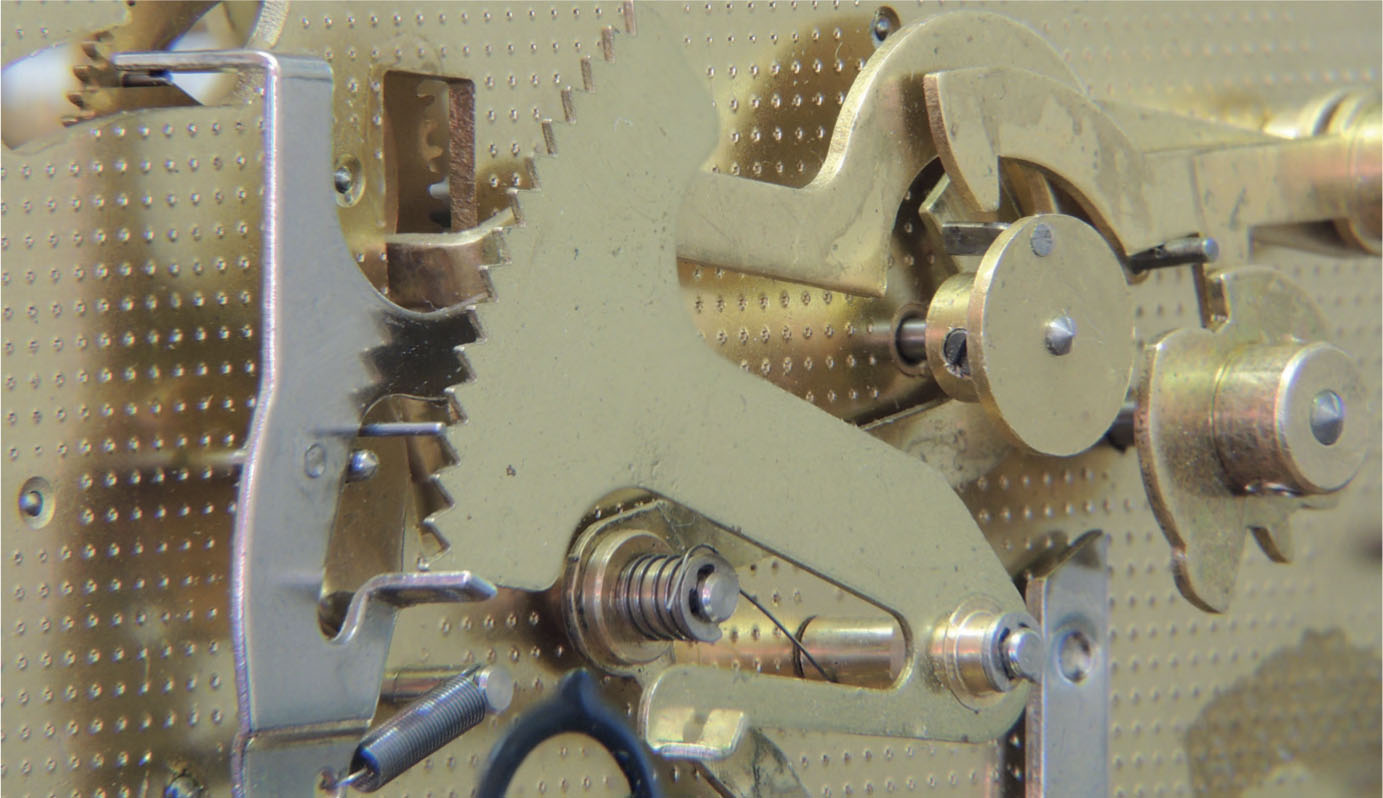

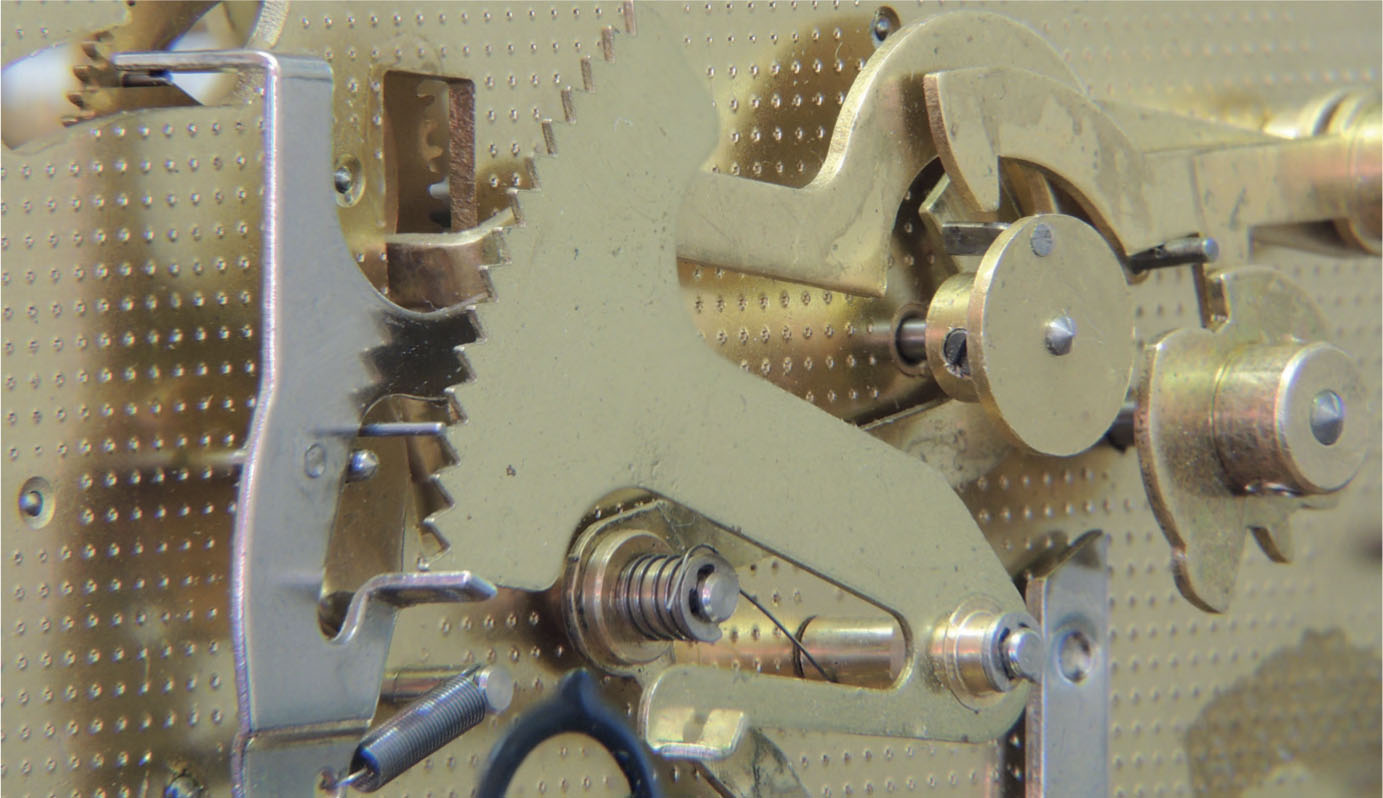

A striking carriage clock being disassembled for cleaning. The components are being separated into sub-assemblies for inspection.

An Introductory

Guide to Repairing

Mechanical

Clocks

Scott Jeffery MBHI

THE CROWOOD PRESS

First published in 2016 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2016

Scott Jeffery 2016

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 093 5

Acknowledgements

I would like to give special thanks to the following for their support, advice and encouragement throughout the process of writing this book: Chris Baldwin CMBHI; Luke Jeffery MA; Charlotte Shilling; and James Shilling. I would also like to thank the many skilled and educated craftspeople who played a valuable role in my training and education.

Contents

Chapter 1

Introduction

In my first four years as a clock repairer I have served my apprenticeship under the watchful eye of Chris Baldwin CMBHI, achieved MBHI certification, run a profitable clock repair business and been commissioned to write this book. Getting to this stage has been challenging and inspiring, and my intentions with this book are to guide you through what I have come to see as the minimum of knowledge and understanding it takes to become a competent repairer of basic mechanical clocks in the quickest amount of time possible, while still allowing plenty of scope for future developments in the knowledge, experience and equipment it takes to become excellent in the field. I have done all I can to re-imagine my first year, and to write this book in a manner which I would have found easy to understand while being technically interesting.

My biggest challenge was to limit this book to the true beginner, to not delve too deeply into the many subjects of horology and, above all else, to keep it interesting.

Deep theory has always failed to hold my attention for long. The detail given to mathematical examples and long-winded explanations can make reading chapters on theory a real chore. To combat this I have kept the theory portion of this book on a need-to-know basis, but there is a lot to be said. I have opted to leave out any unnecessary mention of historical aspects in order to keep the words flowing and to keep the reader in a technical mindset. Photographs have been provided where I feel you could benefit from their presence, and the accompanying explanations have been written to work with them. In this way you are able to see the components being discussed as though you were sitting with me at the workbench.

My intentions are to make the reader aware of the existence of the many components and theories which they are likely to come across in their first year on the job and not to provide a full in-depth study of each. With the understanding that things such as thermal expansion or circular error exist, you are able to make informed decisions. You do not need to be able to calculate it to perform a good-quality repair.

Being relatively new to the industry myself, I completely understand the position of the reader, and what some might see as a disadvantage I use to my advantage.

There are specialist tools for every job, but which ones do you actually need to get it done? Do you really need to invest in a full workshop, ultrasonic cleaning equipment and various lathes just to repair your great-grandmothers mantel clock? It is unlikely. I have put together a tier system to help you define your needs and buy the necessary level of equipment to suit. These are the three toolboxes.

If you intend to turn this hobby into a business, full- or part-time, I highly recommend that you contact the British Horological Institute and enrol in their Technician-grade Diploma in clock and watch servicing, and get a qualification under your belt, wherever you are in the world. It can be studied as a distance learning course in your own time, as I did, and it will provide you with certification, industry contacts, a good reputation and all the help and support you could need. For those of you studying the course already, I hope this book will prove helpful in demonstrating the repair processes to you in a real-life scenario and in compiling the theory into a well-organized, readable and uninterrupted whole.

An early 20th century carriage clock, complete with original winding key and travel box.

The front plate of a modern Westminster chiming longcase.

For more information on some of these repair processes, video tutorials, gear train calculators, or just to say hi, I can be reached by visiting www.learnclockrepair.com or www.hampshireclockworks.co.uk.

Enjoy!

Scott Jeffery, BSc, MBHI

Chapter 2

The Clock Repairers Three Toolboxes

I have split the relevant tooling of my own workshop into three separate categories, or toolboxes. These three toolboxes are intended for:

- the beginner who wants only to make small repairs, and perform routine maintenance

- the enthusiast who intends to complete the majority of their own repairs and those of friends

- the aspiring professional, who intends to undertake repairs for profit.

For every process demonstrated and explained within this guide, I note which toolbox you will need in order to complete it to a high standard. If the job requires tooling which you have not yet acquired, I suggest you buy just the tools needed and slowly build up to the next toolbox. However, if it is a once-in-a-lifetime repair for your interest level, outsource it to a competent, qualified professional who can be found at www.bhi.co.uk.

TOOLBOX 1: THE ABSOLUTE MINIMUM

This toolbox will help you to keep your clock running and extend the period between services, and ultimately keep the costs of those services down. For minimum expenditure, these tools will allow you to regularly oil your clock, repair common breakages and make adjustments to correct the more common issues which may arise. Eventually the time will come when pivots are worn and you will have the choice of either taking your clock to a repairer for overhaul, or upgrading to Toolbox 2 and doing it yourself.

The tools I recommend here are the ones I use most often. I have not suggested makes or names except where offering details of my own equipment because this is not an important part of the choice. What is important to remember is that many of the clocks you will encounter were made two hundred or more years ago, with basic handmade tools which were properly sharpened and well maintained. Provided you use them correctly and with care, the cheapest tool can last a lifetime. Abuse them, and even the named brands will not hold up.