UK

Southern Watch and Clock Supplies Ltd, High St, Orpington, Kent BR6 0JH

Meadows and Passmore, Farningham Road, Crowborough, East Sussex TN6 2JP

Mahoney Assocs, 58 Stapleton Road, Bristol 5

H. S. Walsh and Sons Ltd, 243 Beckenham Road, Beckenham, Kent BR3 4TS

Nathan Shestopal Ltd, Unit 2, Sapcote Trading Centre, 374 High Rd, Willesden NW10

A. G. Thomas (Bradford) Ltd, Tompion House, Heaton Road, Bradford BD8 8RB

R. E. Rose, 731 Sidcup Road, Eltham, London SE9

A. Shoot and Sons Ltd, Renata House, 116118 St John Street, London EC1

J.M.W. (Clocks), 12 Norton Green Close, Sheffield, Yorks S8 8BP

Chronos, 95 Victoria Street, St Albans, Herts

P. P. Thornton Successors Ltd, Old Bakehouse, Upper Tysoe, Warwickshire CV35 0TR

Geoffrey Booth, Tower House, Tower Hill, Bere Regis, Wareham, Dorset BH20 7JA

Richards of Burton, Woodhouse Clock Works, Swadlincote Road, Woodville, Burton-upon-Trent DE11 8DA

Collins, 99 Venable Avenue, Colne, Lancs BB8 7DH

Jones and Chambault, Gronfa, Station Road, Clynderwen, Dyfed SA66 7NF

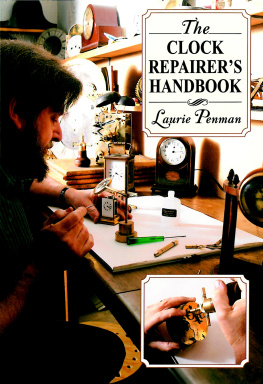

Laurie Penman, Castle Workshop, High Street, Totnes, Devon TQ9 5PB

USA

The Cas-Ker Company, P.O. Box 2347, 128 East 6th Street, Cincinnatti, OH 45201

Esslinger & Company, 1165 Medallion Drive, St. Paul, MN 55120

The Gould Company, 13750 Neutron Road, Dallas, TX 75234

Herr & Kline Inc., 1914 Granby Street, Norfolk, VA 23517

S. LaRose, Inc., 234 Commerce Place, Greensboro, NC 27420

Marshall-Swartchild Company, 2040 North Milwaukee Avenue., Chicago, IL 60647

Mason and Sullivan Company, 586 Higgins Crowell Road, West Yarmouth, Cape Cod, MA 02673

The Nest Company, 915 Olive Street, St. Louis, MO 63101

E & J S wigart Company, 34 West Sixth Street, Cincinnatti, OH 45202

Tani Engineering, 6226 Waterloo, Box 338, Atwater, OH 44201

Additional supplier listings may be found in the Watch and Clockmakers Buyers Guide published by the American Watchmakers Institute, 3700 Harrison Avenue, Cincinnati, Ohio 45211.

DIAL RESTORATION

Rob Gillies, 38 Maltravers, Arundel, West Sussex

John Pearson, Church Cottage, Birstwith, Harrogate, Yorkshire

John Sawyer, 78 Bicester Road, Kidlington, Oxford

John E. Peters, 3 Arthur Road, Rainham, Kent ME8 9BT

Steve Collis, 58 Appleton Road, South Benfleet, Southend

Alan J. Thom, 55 Athens Street, Stockport SK1 4EG

Clive and Lesley Cobb, Newhouse Farm, Bratton Fleming, Barnstaple EX31 43T

Laurie Penman, Castle Workshop, High St, Totnes, Devon TQ9 5PB

FURTHER READING

UK

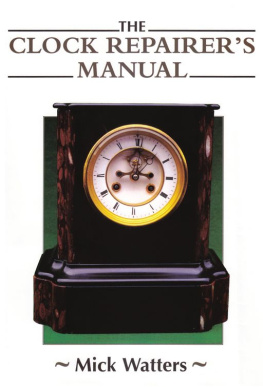

Britten, F. J. Watch and Clockmakers Handbook (Eyre Methuen, 1978)

De Carle, D. Practical Clock Repairing (NAG, 1968)

Gazeley, W. J. Watch and Clock Making and Repairing (Newnes Butterworth, 1971)

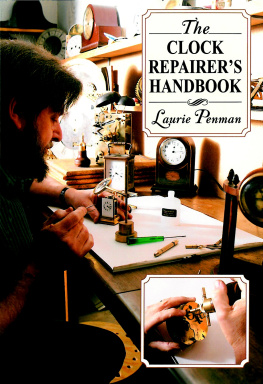

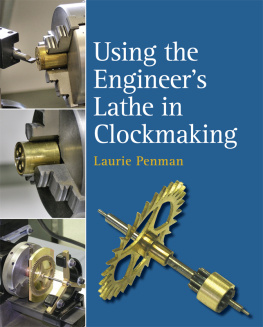

Penman, L. Clock Design and Construction (Argus, 1984)

Rawlings, A. L. Science of Clocks and Watches (EP, 1974)

Wild, J. M. Clock Wheel and Pinion Cutting (Argus, 1983)

USA

Harris, H. R. Nineteenth Century American Clocks (Emerson Books, 1981) Questions and Answers of and for the Clockmaking Profession (AWI Press)

Monk, Sean C. Essence of Clock Repair (AWI Press)

Palmer, B. Treasury of American Clocks (Macmillan Publishing, 1967)

Rudolph, J. S. Build Your Own Working Clock (Harper and Row, 1983)

Tyler, E. J. American Clocks for the Collector (E. P. Dutton, 1981)

Whiten, A. J. Repairing Old Clocks and Watches (Van Nostrand Rheinhold, 1981)

Other books available from American Watchmakers Institute, P.O. Box 11011, Cincinnati, Ohio 45211. Contact them for a current catalog.

Finding Clock Faults

This first chapter is intended as a quick reference aid for solving clock repairing problems. Most of the solutions are not set out in great detail the other chapters do that. Here I simply try to help you to locate the problem and to give a little help in making what may be perfectly obvious corrections. On occasion you will find that there are two solutions proposed, one in this chapter and another in the specialised chapter. There is frequently more than one good solution to a problem and this is a convenient method of showing them.

FAULTS COMMON TO MOST CLOCKS

Diagnosis

The first necessity is diagnosis. Often the locality of the fault is clear: a hand is catching on the dial, or a gear is badly damaged, for instance. But this is not always so and it is worthwhile adopting a simple pattern of testing that will assist in finding faults. Of course the clock may be so dirty that it does not have a hope of going until the dirt and old oil has been removed. In this event it is useful to take the movement out of its case and carry out a crude (but safe) dunking in paraffin (kerosene) that contains about 5 per cent of good lubricating oil. After draining it should be possible to proceed with the following tests. Do remember that this is not a proper cleaning; it is simply a means of loosening-up the clock for testing.

Consider the clock as a series of systems connected together and test each system in succession. The first thing to test is the power. Is the clock wound up? Is the mains or battery supply making a proper connection? Then test as follows:

- Open any part of the case that can, conceivably, come into contact with any part of the movement (including weights and pendulum).

- Check to see if the clock will run now. This check follows each test.

- Remove the hands or disconnect the display.

- Remove the dial.

- Remove the pendulum. Many clocks will need the crutch adjusted to put it in beat. Recoil escapements will run without anything further being done, but dead-beat escapements need a little weight added to the crutch so that it will unlock the escape wheel. Blu-tack or a similar stick-on product performs this service very well.

- Remove the hour and minute pipes.

If the clock runs after carrying out any one of these tests, the fault lies in the part that has just been removed. In a movement that has been working for years, you will most probably have to carry on and strip and clean the complete movement in a proper fashion (see Chapter 2). The tests should ensure that you do not waste time in correcting parts that look suspicious but in fact are working satisfactorily, or in taking a movement apart when the fault is caused by some exterior factor. After repairing the movement there is sometimes a disappointing lack of response from the mechanism. Repeat this series of tests do not assume that there is an undiscovered fault in the movement until you have proved it, for life is too short to strip clock movements unnecessarily. Besides it is not fair on the clock. It is always best not to strip a clock if there is no sign of dirt, stiff oil or obvious wear or corrosion. The wheels and pinions will have worn together over the years and if the wheel count of teeth is precisely divisible by the pinion count, each leaf will have its own set of wheel teeth that it complements. Changing the set of wheel teeth that each leaf meshes with, will leave a meshing of wheel and pinion that is not as good as existed before dismantling. (This is the main reason for filing or stoning out any pocketing of the pinion leaves.) A movement does not need dismantling if it operates and: