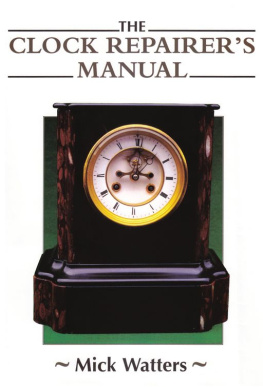

Diagnosis

The first necessity is diagnosis. Often the locality of the fault is clear: a hand is catching on the dial, or a gear is badly damaged, for instance. But this is not always so and it is worthwhile adopting a simple pattern of testing that will assist in finding faults. Of course the clock may be so dirty that it does not have a hope of going until the dirt and old oil has been removed. In this event it is useful to take the movement out of its case and carry out a crude (but safe) dunking in paraffin (kerosene) that contains about 5 per cent of good lubricating oil. After draining it should be possible to proceed with the following tests. Do remember that this is not a proper cleaning; it is simply a means of loosening-up the clock for testing.

Consider the clock as a series of systems connected together and test each system in succession. The first thing to test is the power. Is the clock wound up? Is the mains or battery supply making a proper connection? Then test as follows:

- Open any part of the case that can, conceivably, come into contact with any part of the movement (including weights and pendulum).

- Check to see if the clock will run now. This check follows each test.

- Remove the hands or disconnect the display.

- Remove the dial.

- Remove the pendulum. Many clocks will need the crutch adjusted to put it in beat. Recoil escapements will run without anything further being done, but dead-beat escapements need a little weight added to the crutch so that it will unlock the escape wheel. Blu-tack or a similar stick-on product performs this service very well.

- Remove the hour and minute pipes.

If the clock runs after carrying out any one of these tests, the fault lies in the part that has just been removed. In a movement that has been working for years, you will most probably have to carry on and strip and clean the complete movement in a proper fashion (see Chapter 2). The tests should ensure that you do not waste time in correcting parts that look suspicious but in fact are working satisfactorily, or in taking a movement apart when the fault is caused by some exterior factor. After repairing the movement there is sometimes a disappointing lack of response from the mechanism. Repeat this series of tests do not assume that there is an undiscovered fault in the movement until you have proved it, for life is too short to strip clock movements unnecessarily. Besides it is not fair on the clock. It is always best not to strip a clock if there is no sign of dirt, stiff oil or obvious wear or corrosion. The wheels and pinions will have worn together over the years and if the wheel count of teeth is precisely divisible by the pinion count, each leaf will have its own set of wheel teeth that it complements. Changing the set of wheel teeth that each leaf meshes with, will leave a meshing of wheel and pinion that is not as good as existed before dismantling. (This is the main reason for filing or stoning out any pocketing of the pinion leaves.) A movement does not need dismantling if it operates and:

It is clean, with no stiff oil or varnish.

It has slight pocketing but no evidence of black or metallic particles.

It has sloppy holes that are round, with no evident wear of the pivots.

In those few movements that hold the escapement pallet arbor between the clock plates, if:

the escape pallet arbor does not lift as the wheel rotates.

In longcase or grandfather clocks, if they:

stop at the same day each week (eight-day clocks).

stop at the same hour each day (thirty-hour clocks).

These last two faults typify those that disappear when the case door is left open, and are a result of sympathetic vibration.

OPENING THE CASE

This first test should eliminate stoppages due to the hands fouling the glass and, in weight-driven pendulum clocks, any impedence to the steady fall of the weights. It will also allow you to see if the pendulum and weights touch at some part of the clocks going, or if there is any sympathetic vibration. All these will be fairly obvious, but sympathetic vibration is unusual and, when it occurs, quite difficult to spot. At a time when the weight cords have unwound to approximately the same length as the pendulum, there is a tendency for the weight or weights to oscillate in harmony with the pendulum bob. This may be sufficient to rock the seat board or case if they are imperfectly supported, or cause interference between pendulum, weights or case. In any event the clock will show the habit of stopping, for instance, every fourth day, or always at three oclock in the morning. The cure for sympathetic vibration is to improve the support of seat board and case in extreme cases associated with very heavy clock weights fasten the case to the wall and to ensure that there is plenty of space between the weights and the bob at the time when they are almost level. Clocks often have two suspension positions (), and moving the pendulum from one to the other of these will change the position of the bob in relation to the weights and the case. The position of the cord anchorage on the seat board will also affect the position of the weights in relation to the door or pendulum bob as the cord unwinds and the weight moves over in the direction of this anchorage.