I thank Cynthia Boult who was consulted over the cover, colleagues at St Loyes College Foundation , particularly Peter Mitchell and Mike Western for their advice and support on technical matters, and to the trainees of St Loyes College through whom I have learned so much.

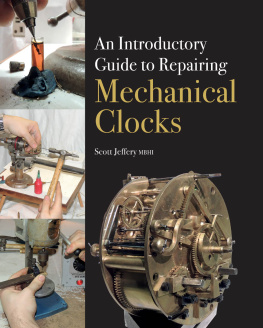

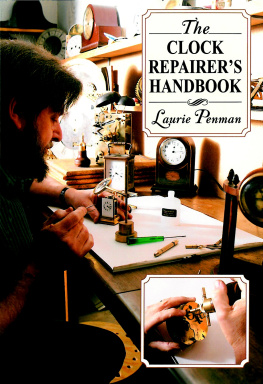

This book was written primarily for the horological enthusiast interested in taking that first step into clock repairing and for those under initial training in clock repairing. There is likely to be material which will benefit the professional repairer as well. For example I have never read in any book how to splice a twelve strand long case clock rope. It is included here.

Those completely new to clock repairing will be led gently into new skills and knowledge. It is the intention that this book will inform about techniques and give you the confidence to have a go. It is also the intention that those with limited experience will extend their ambitions.

You will find here a mix of imperial and metric units reflecting the speed of change within industry generally. For example, steel continues to be supplied in imperial units so dont be surprised if you are asked to select inch brass and set up in a Number 32, (3.2mm), collet.

Two early considerations for those preparing to repair clocks from home, whether as pure e nthusiast or professional, are where to work and what tools will be needed to make a modest start.

Where to work will include alternatives such as a shed, an outhouse, a loft conversion, a utility room or a garage; otherwise an existing workshop might be converted, or the lounge, dining-room, kitchen or even the bedroom utilized. Perhaps initially working in a bedroom doesnt seem realistic , but in fact making or converting a double wardrobe into a work station is very sensible. There are significant advantages to working in a bedroom: there is minimal disturbance from other users of the house, and work in progress may be left from one day to another yet to anyone entering, the work station would appear to be an ordinary double wardrobe.

Certainly working inside the house offers the advantage of comparative warmth in the winter months. The disadvantage of working in a lounge, dining-room or kitchen is having to clear things away even as work progresses.

Next to be considered are the workbench, storage space, light and a chair to sit on.

THE WORKBENCH

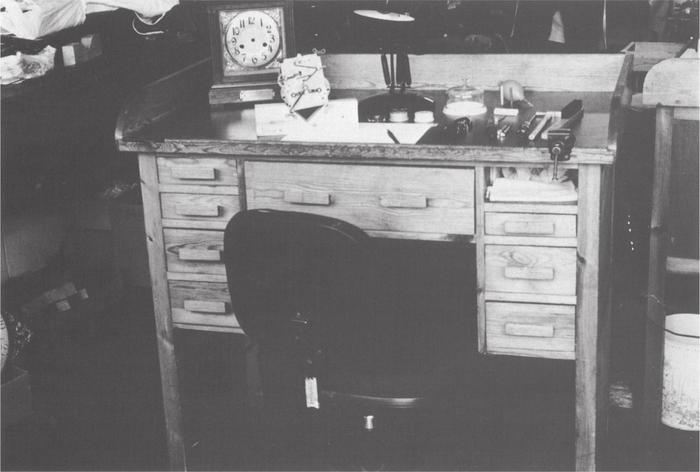

Many hours are likely to be spent sitting at the workbench, so it must be the right size and shape for your comfort and health, and strong enough for the work that is to be undertaken. It should enable you to work occasionally with both elbows resting on its surface, and with an upright back.

A good height for a clock repairers bench is about 92cm (an approximate conversion from the traditional imperial height of 36in). A minimum width should also be about 92cm (36in), though if room permits, a bench 107cm (42in) wide would allow a small vice to be permanently attached to the bench top at one end; it would then be available for immediate use but without getting in the way during other bench work. The depth of the bench should be a minimum of 46cm (18in), but 61cm (24in) if space permits; this will allow for the work in hand and offer room for various tools that will be needed as work progresses.

The bench top should be about 2.5cm (1in) thick, or more if possible, to take light hammering and heavy clocks. The surface should be covered with plain brown or light green cork lino or a plain vinyl; it is better to make the surface as plain as possible so that small parts can be seen easily on the surface. The sides and back of the bench should have high edging to contain items on the bench, and the front should have a low edging, for comfort yet also to prevent items from rolling off.

Small drawers under the bench will help with storage for tools and materials. The storage should be well off the floor as it is essential to be able to sweep under the bench to find small parts that will inevitably find their way there. Every potential clock repairer should be aware that small clock components can spontaneously grow both wings and legs and will discover the most inaccessible places to hide in.

The bench should be well lit, with either a twin balanced fluorescent tube lamp or a tungsten lamp with a 40 watt pearl bulb. A stronger bulb will have the disadvantage of throwing out too much heat. Some repairers advocate working by a natural north light, but this is far from essential. Working with sunlight falling directly on the bench is very uncomfortable, not so much because of the heat but because of the uncomfortable light. A blind should overcome the problem of direct sunlight falling on the bench.

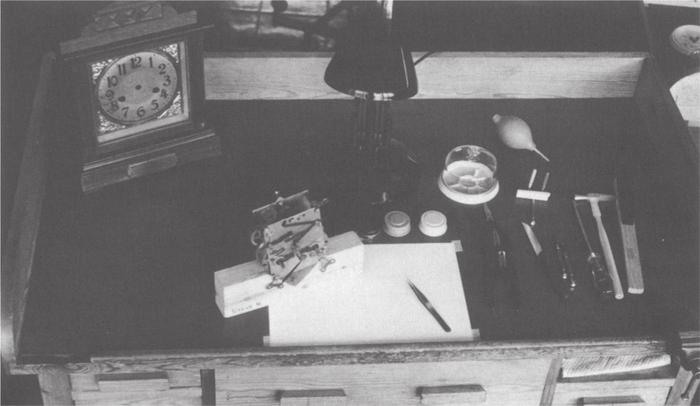

Finally a working surface, often of plain white A4 paper, is secured to the bench in front of the repairer.

If the luxury of a purpose-built, dedicated bench is not possible, a table top will do, although raising the working level with blocks or a false top will be more comfortable. The surface of a table top will need protecting to avoid scratches.

A further space with a working surface will be necessary for clock cleaning and other dirty or heavy work. Certainly an outhouse or garage is better suited to some work, but is not essential for a modest start.

Working heights vary so a chair that can be adjusted between about 46cm and 61cm (18 and 24in) should ensure a comfortable working position. A back to the chair is preferable.

TOOLS

For anyone just beginning in clock repairing, the thought of a significant outlay on tools would perhaps be off-putting. In fact much can be achieved with ordinary tools found in the home. Inevitably as knowledge and skills are gained, the desire for specialist tools will increase; but these can be acquired over a long period, perhaps being paid for by repairs carried out.

Tools need not be new, of course, and the repairer is encouraged to attend some of the many horological tool auctions held across the country. British Horological Institute branches often hold local auctions which members of the public may attend; BHI branch secretaries will have advance notice of pending auctions, and their addresses may be obtained from the secretary of the BHI.

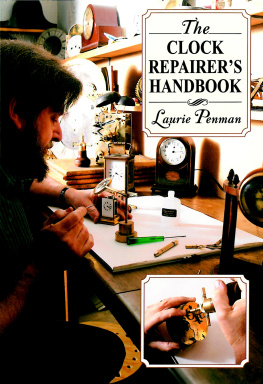

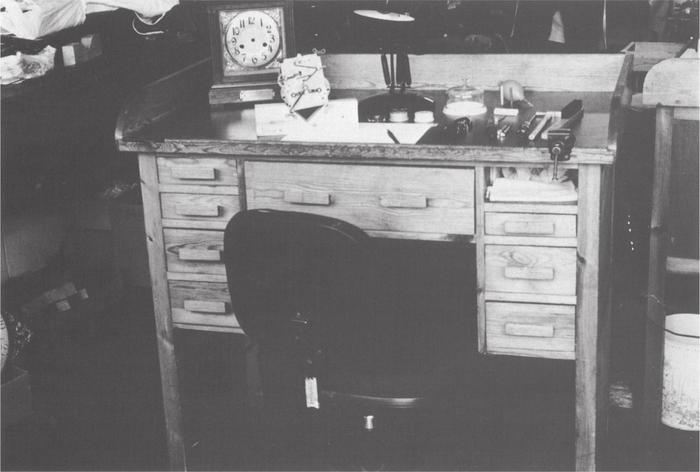

Fig1Anidealclockrepairersbench.

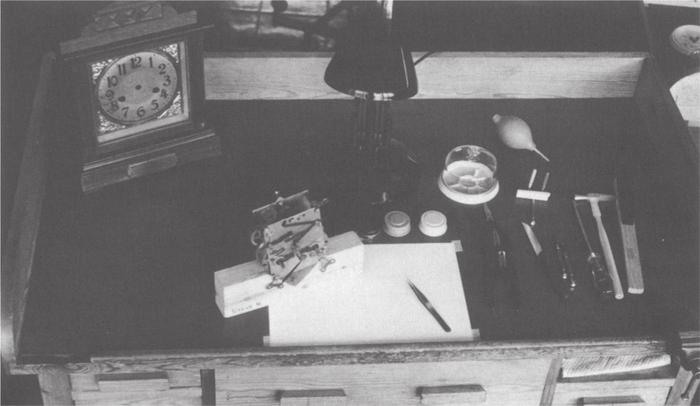

Fig2Aclockrepairersbenchlaidoutwiththetoolsinconstantdailyuse.

The absolute minimum needed to get started will be small flat nose pliers, a variety of small screwdrivers, one or two small plastic containers to hold parts, and a pair of tweezers. For those who wish to purchase a more comprehensive range of specialist tools the following are recommended , and should cost no more than the equipment needed for many other activities such as archery, fishing, mountain biking or photography . These may be purchased from tool and material houses or from second-hand sources.

Tool List

Tweezers, general purpose