Contents

Guide

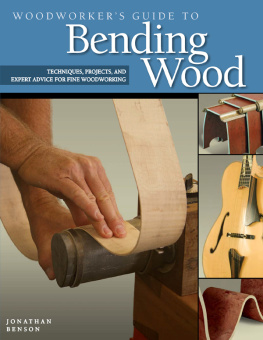

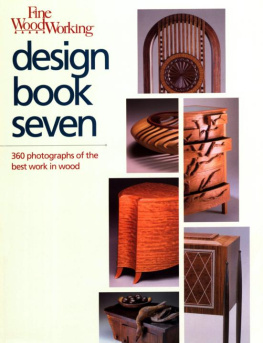

The curved chair arm in this close-up photo was made by gluing many thin layers of wood together. This is a good way to make curved parts. Larry and Nancy Buechley, Wishbone III detail, cherry and leather.

Dedication

To Laura and Sarah.

Lara Finley, Rocking Bench detail, laminate-bent white oak, 2003. Photo courtesy The Furniture Society Curv-iture exhibition.

Acknowledgments

I have been working with wood for more than 30 years. During that time, I have been lucky to cross paths with so many knowledgeable and insightful individuals, including teachers, students, clients, gallery owners, editors, and fellow woodworkers. Their enthusiasm, knowledge, and insights greatly contributed to the inspiration for this book. As I continue exploring this exciting field, I stand on the foundation that they have created.

I would like to thank those who contributed material to this book, including Bob Saunders of the Prairie Rose Woodworking Studio, for his instrument-making expertise; Jim Anderson for his beautiful bentwood boxes, and Darryl Keil of Vacuum Pressing Systems, for innovative pictures of the vacuum press. I enjoyed the exchange of ideas with John Kelsey as we worked on the photography in the shop. This book was also greatly enhanced by the editorial work of Gretchen Bacon and the staff at Fox Chapel Publishing.

This book would not have been possible without the love and support of my wife, Sherry.

About This Book

Wood is stiff, straight, flat, and, well, wooden.

Wood comes from trees, which are supple and alive.

When its cut into boards and dried, its really flat and stiff.

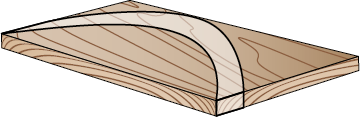

Curves sawn out of solid wood have weak short grain, and a lot of wasted wood.

But what if you could bend wood? Would you be able to create designs you never thought possible?

If you could bend wood, you could make chairs like this...

Bentwood chair (2007) by Jonathan Benson was made by bending fresh-cut willow saplings and branches. Green wood is supple and easy to bend; when it dries the curves set.

Miles (2002) by George Mahoney of Minneapolis, Minnesota, features curved parts made by laminate-bending thin layers of birch around a form. Photo courtesy The Furniture Society.

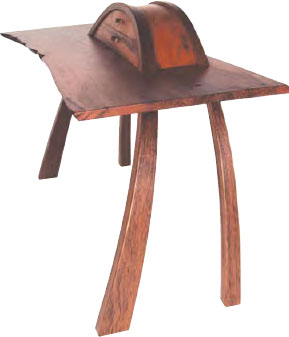

tables like this...

Arched Writing Desk (2001) by Matthew Steckley of Coral Gables, Florida, has legs laminated from many thin layers of wood. Photo courtesy The Furniture Society.

Constructivist Coffee Table by Jonathan Benson features a wave-shaped stretcher made by gluing many thin layers of walnut veneer together over a form. The semicircular legs are not bent wood, but rather were turned from solid walnut; the top is granite.

boxes like this...

Nordic-inspired box by Jim Andersen has thin sides made from birds-eye maple bent over a hot pipe, with curved handles carved from solid wood. Curvaceous guitar sides can be bent in the same way.

and any other curvy thing you might want to make out of wood.

Toboggans are made by steam-bending white oak around a form.

The possibilities are endless.

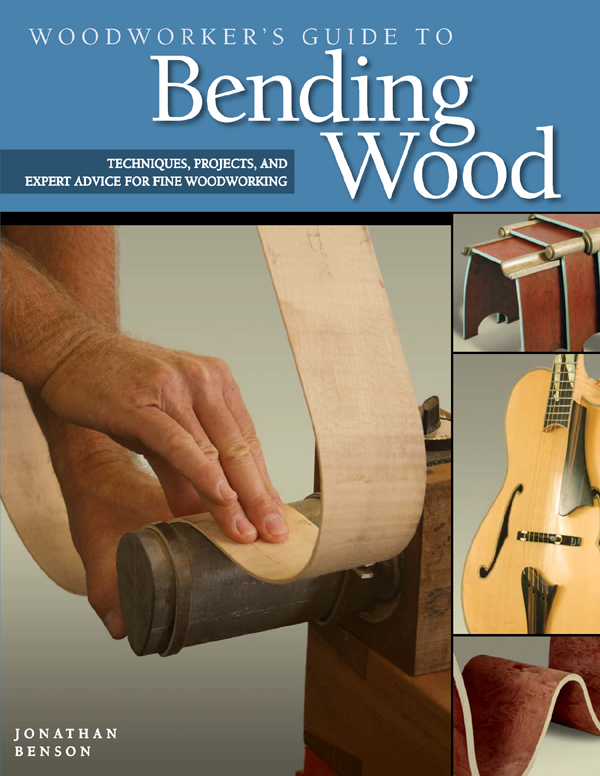

This book teaches you the four principal methods for bending wood, and how to choose and apply the one that best suits your project.

Bending green wood...

bending with heat, water, and steam...

...bending with heat, ...bending thin layers of solid wood and gluing them together..

...bending plywood panels and veneer faces.

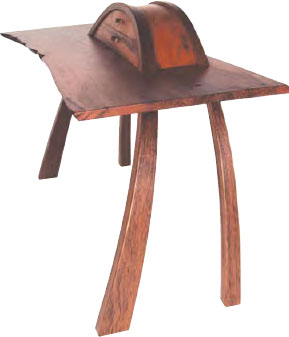

Figure i. Jonathan Benson, End Table, solid cherry and laminate-bent veneer, 2008.

Contents

Figure ii. Heres the top of the curved leg on the demonstration cabinet youll be seeing throughout this book. The legs, drawer fronts, door rails and panels, and front edge banding are all bent laminations. The leg-to-case joint is a tenon reinforced with screws.

Introduction

I began learning about woodworking by constructing objects that primarily consisted of straight lines, flat planes, and right angles. Working with straight lines is the best way to develop the skills to create objects from wood. When I began designing, I was drawn to curves. To me, curves complement the organic nature of wood. The grain pattern of most wood is not straight, but curvaceous and undulating, which seems to call for some sort of curve.