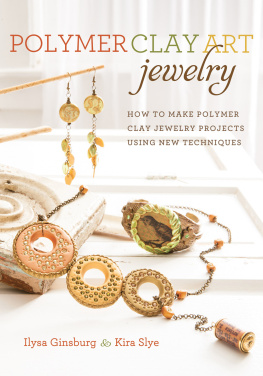

Dedicated to Luck and Dan for their love and support. And to baby Adeline, welcome to our crazy, crafty family.

ACKNOWLEDGMENTS

Thanks to our friends and family who encouraged us with ideas and support. Thanks to Zachary Williams for the great photos. Much appreciation goes to the editors, production staff, and designers at Potter Craft who worked so hard on this book. And a big thank-you to the artists, working with this exciting material, who kindly provided projects and gallery photos.

Contents

CHAPTER 1

Resin Clay Essentials

CHAPTER 2

Imitative Techniques

CHAPTER 3

Creating Bezels

CHAPTER 4

Mixing Resin Clay with Other Mediums

CHAPTER 5

Molding and Sculpting Techniques

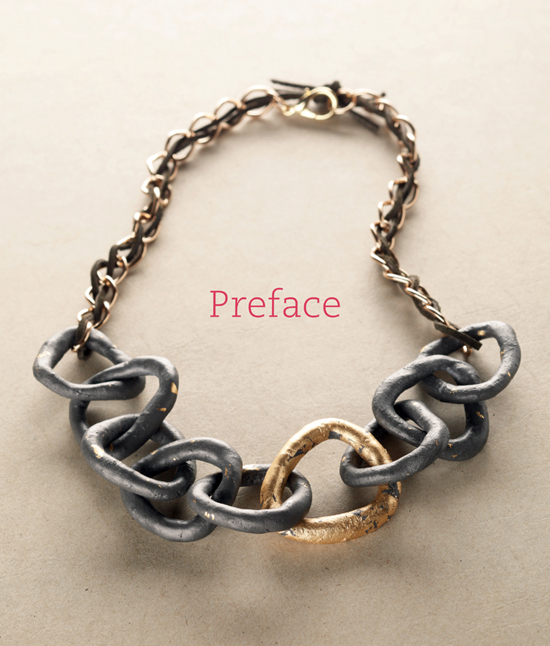

Resin claya craft clay that contains a plastic component such as a polymer or a resin and cures without heatis fast becoming an exciting medium for use in jewelry making and other crafts. Until recently, one-part resin clays (also referred to as air-dry clays) were often regarded only as a childrens crafts material, while many two-part versions (generically known as epoxy resin clays) were familiar only to artisans and tradespeople who use them to make large-scale sculptures, industrial repairs, taxidermy, and dolls.

Our discovery and interest in resin clay came after observing an artist who used it to make a rhinestone-studded doll dress. We were impressed that the clay didnt require heat to cure, which is always required with polymer clay. We were also amazed that the resin acted as an adhesive that held the stones in place without the need for glue. These features were enough to spark our interest in its potential for jewelry making.

As we started playing around with the various clays, each of us developed her own style of working with the material. And early on, when we brought it to jewelry workshops, creative people came up with more fabulous designs than we thought possible. More features and techniques emerged quickly, and the material proved so versatile we felt compelled to share what we learned. This enthusiasm inspired the projects in this book, which we hope will be a catalyst for you to discover new ideas.

While resin clays may appear similar to polymer clays, there are differences in physical characteristics, handling, and end results that set them apart and allow them to yield unique designs. Because they dont require heating or baking to cure, heat-sensitive materials such as plastics, sequins, and pigments can be embedded into the clay. Oversize beads that are both lightweight and strong are easy to make by covering Styrofoam spheres with a thin layer of resin clay (see the ). These techniques simply arent possible with polymer clay. A material such as Styrofoam would either melt or emit toxic fumes when heated or baked.

Both one- and two-part resin clays have adhesive properties, but the two-part clays are particularly sticky, so working with them is essentially like working with moldable glue. Not only will these clays stick effortlessly to an armature or other underlying form, but materials such as embedded rhinestones or wires generally wont need a separate adhesive to create a strong bond.

Different types and brands of clay cure at different rates, which can be used to advantage when designing and creating projects. For example, you can use a quick-curing clay to create a cuff bracelet by shaping it right on your wrist (see ). Other clays take longer to set up, which allows time to finesse a sculptural design, or even to start over if necessary.

Resin clays can also be made to mimic a variety of surfaces and other materials. By adding paints, pigment powders, and other inclusions, these clays can be enhanced to achieve a variety of imitative effects, including food, bone, pottery, and many others. One brand of resin clay even offers a concrete version that contains aggregate similar to actual concrete, which helps give it a rough, realistic appearance.

As we worked with the clays to better understand their components and characteristics, we found a few welcome surprises that led to new techniques. With two-part resin clay, for example, we discovered that laser-printer images can be easily transferred simply by pressing the image onto the uncured clay surface while still soft. We then realized that this feature could be used to replicate painted or antique effects such as scrimshaw, porcelain, or vintage tintypes.

With their many distinctive properties, we think youll find resin clays to be an exciting addition to your jewelry- and craft-making supplies. As you use them, youll be discovering a new crafts medium, along with techniques you may never have thought were possible to achieve with any other clay medium.

R esin clay is an exciting new medium for serious jewelry making. There are many brands available from suppliers who carry sculpting clays. Most resin clays can be found online, and a few brands are now in craft stores. Resin clays vary in formulation, color options, texture, strength, and curing times. We divide the clays in this book into two basic types: two-part resin clays and air-dry clays. Youll find that some of the same general information applies to each type, regardless of brand. For example, all two-part resin clays are mixed in a one-to-one ratio. And two-part clays cure, whereas air-dry clays dry. In this chapter, youll learn basic guidelines for working with these clays, as well as for sculpting, adding color, and understanding curing times and strength properties.