Published in 2018 by Cavendish Square Publishing, LLC

243 5th Avenue, Suite 136, New York, NY 10016

Copyright 2018 by Cavendish Square Publishing, LLC

First Edition

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means-electronic, mechanical, photocopying, recording, or otherwise-without the prior permission of the copyright owner. Request for permission should be addressed to Permissions, Cavendish Square Publishing, 243 5th Avenue, Suite 136, New York, NY 10016. Tel (877) 980-4450; fax (877) 980-4454.

Website: cavendishsq.com

This publication represents the opinions and views of the author based on his or her personal experience, knowledge, and research. The information in this book serves as a general guide only. The author and publisher have used their best efforts in preparing this book and disclaim liability rising directly or indirectly from the use and application of this book.

All websites were available and accurate when this book was sent to press.

Library of Congress Cataloging-in-Publication Data

Names: Boozarjomehri, Keon Arasteh, author. Title: 3D printing at school and makerspaces / Keon Arasteh Boozarjomehri. Description: New York : Cavendish Square Publishing, [2018] | Series: Project learning with 3D printing | Includes bibliographical references and index. Identifiers: LCCN 2017022972 (print) | LCCN 2017024264 (ebook) | ISBN 9781502631497 (E-book) | ISBN 9781502631480 (library bound) | ISBN 9781502634269 (pbk.) Subjects: LCSH: Three-dimensional printing--Juvenile literature. | Student activities--Juvenile literature. Classification: LCC TS171.95 (ebook) | LCC TS171.95 .B66 2018 (print) | DDC 621.9/88--dc23 LC record available at https://lccn.loc.gov/2017022972

Editorial Director: David McNamara

Editor: Fletcher Doyle

Copy Editor: Nathan Heidelberger

Associate Art Director: Amy Greenan

Designer: Alan Sliwinski

Production Coordinator: Karol Szymczuk

Photo Research: J8 Media

The photographs in this book are used by permission and through the courtesy of: Cover, p. 48 Asiseeit/E+/Getty Images; Back cover Jonathan Juursema/Wikimedia Commons/File:Felix 3D Printer - Printing Head.JPG/CC BY SA 3.0; p. 4 Laboratory/ Alamy Stock Photo; p. 8 Anna Webber/Getty Images for Academy of Motion Picture Arts and Sciences; p. 11 Wsfs/Shutterstock.com; p. 14 Cristina M. Fletes/ St. Louis Post-Dispatch/TNS/Getty Images; p. 21, 23, 26 , 28, 29, 34, 38, 42, 45, 59, 61, 68 74,76,78, 80, 88, 94, 96, 98, 101, 103, 109 Keon Boozarjomehri; p. 55 Artyom Geodakyan/TASS/Getty Images; p. 66 Science Photo/Shutterstock.com; p. 90 Carlo Amoruso/Taxi/Getty Images; p. 92 Monkey Business Images/Shutterstock.com.

Printed in the United States of America

CONTENTS

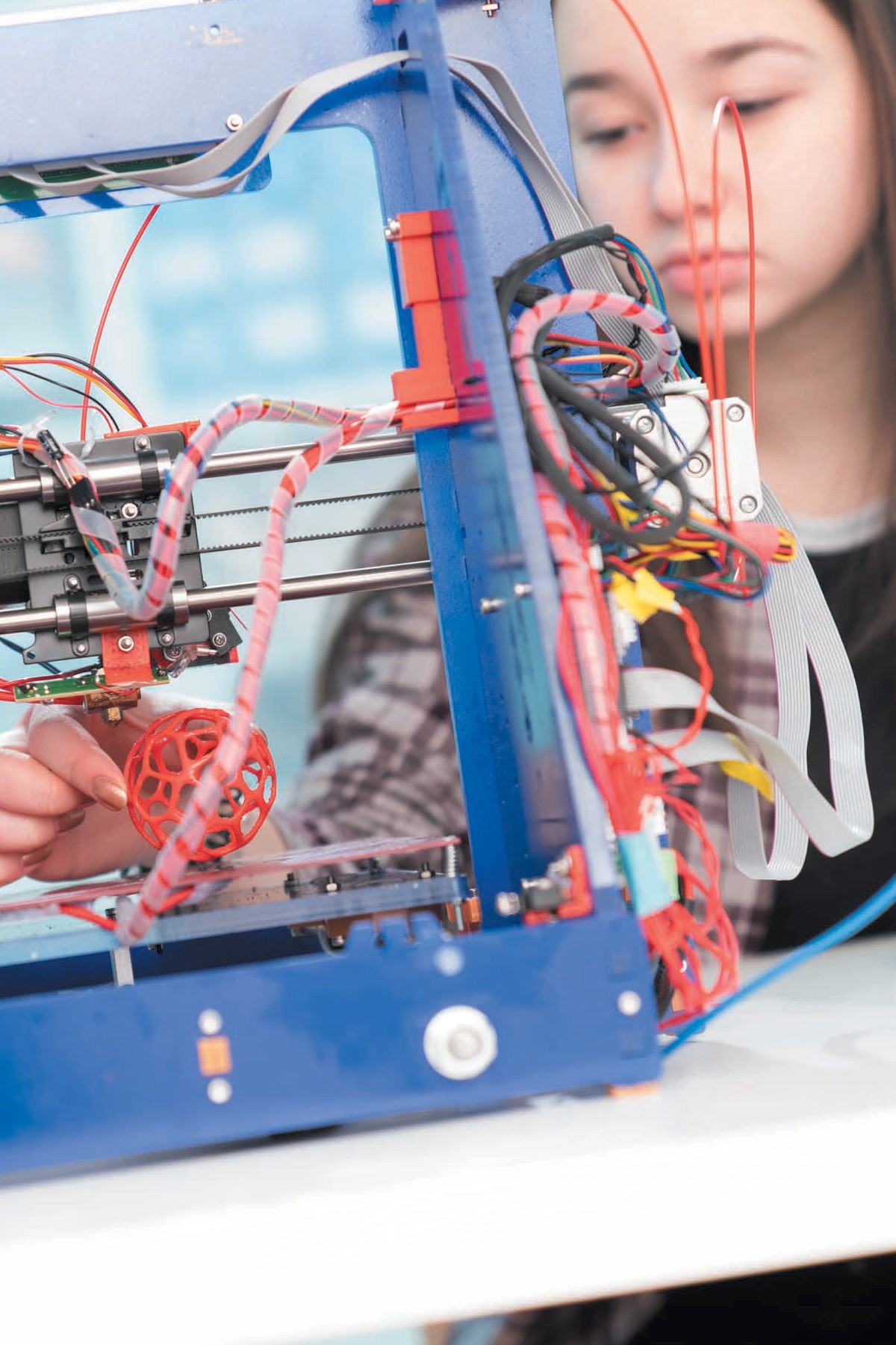

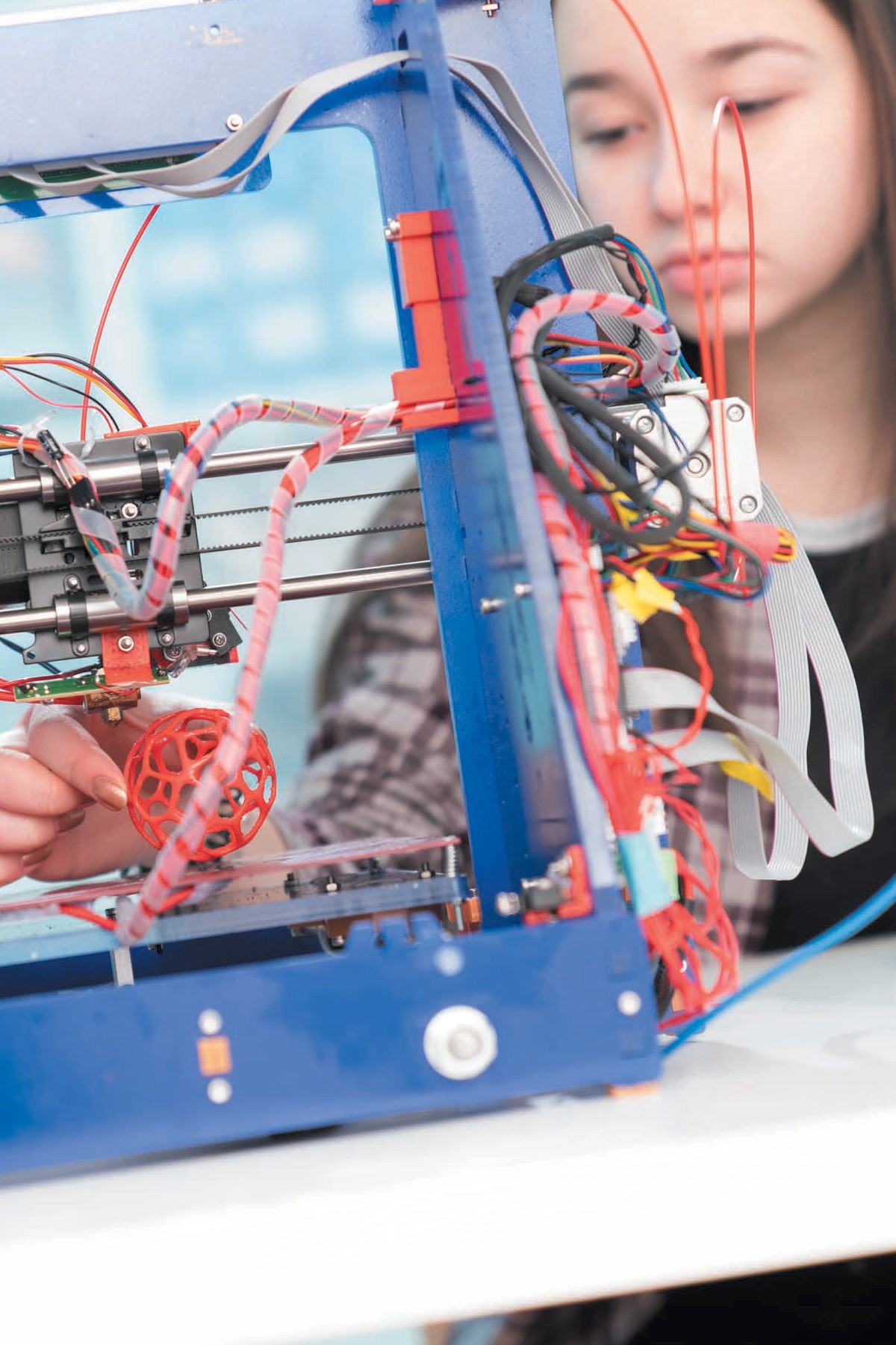

Opposite: Makerspaces give young people a chance to get hands-on experience with a 3D printer.

TECHNICAL TERMS

additive manufacturing The process by which a product or appliance is created by adding materials together. This is usually done by pouring plastic into a mold to create a plastic appliance . 3D printing creates objects by adding plastic or other materials layer by layer to create a 3D object .

open-source Describing original source code or software that is made freely available to be modified and distributed with no limitation .

rapid prototyping The ability to create a work, item, or method that can be altered, modified, and remanufactured for use within a short period of time .

S CHOOLS AND COMMUNITIES ARE SETTING UP MAKERSPACES to give students access to technology that will allow them to create. There is an emphasis on play, so that students can have fun while learning skills they will need for college and in the working world.

These facilities make this technology more accessible and cost effective so families and makers can get started creating. Among the most useful pieces in a makerspace is a 3D printer. While the purpose of a makerspace is to allow students to learn while doing it themselves, often students are required to attend an introductory workshop before using the equipment on their own. This book is intended to be that workshop. It will get you started on your DIY journey.

A 3D printer works in a simple fashion. There are three main methods that 3D printers use to print. These are the most popular and viable methods to print, but they vary a lot. They involve using either resin, lasers, or heating elements. These all achieve creating a 3D model by stacking layers to create an object. This is called additive manufacturing , in which you create something by adding materials to it until there is a final product. Although 3D printing is incredibly popular and seems like cutting-edge technology, it has been around for longer than you might think. The technology has been growing since the 1980s.

In 1980, Dr. Hideo Kodama made the first attempt at 3D printing. He used a technique called SLA printing, which stands for stereolithography apparatus printing. Stereo means from several sources, and lithography means light emission, so stereolithography means emitting light from several sources. This technique uses ultraviolet (UV) light to solidify photosensitive resin in a resin bath. This requires setting a build plate in a bath of resin and projecting light through the resin from above or below onto the plate in a precise manner. By projecting the light at certain angles, the resin solidifies on the plate, creating the first layer. Then the plate is lifted or lowered layer by layer in the bath. As it moves, the UV light projects and solidifies more layers onto the already solidified resin. Thus, a 3D model is printed once all the layers are complete and the 3D model is lifted out of the resin bath. This technology was far ahead of its time and is just now becoming commercially accessible. The most popular consumer-grade SLA printer is called the Form 2, and this printer can create 3D prints in a fraction of the time it takes a regular 3D printer. However, it is far more complicated and requires professional maintenance. Therefore, it is rarely available for use by students.

Tool for Animation

Though Dr. Kodama was the first to attempt SLA printing, he was not the first to succeed and patent the technology. Charles Hull beat him to it in 1986. Hull would go on to found the 3D Systems Corporation. It would release the first SLA printer, called SLA-1, in 1987.

After Hull capitalized on SLA printing, Carl Deckard patented the first selective laser sintering (SLS) technology at the University of Texas in 1988. This technique requires two things: a high-powered laser, and a large solid source of powder grains. This form of printing requires shooting a laser at the powder source. The laser will fuse this powder wherever it is shot. Just as with the SLA printer, the SLS printer goes layer by layer to create its model. This form of printing is incredibly precise and can create beautiful models. The animation studio Laika uses this form of 3D printing to create its stop-motion characters. The animators create and pose them, then color print them with an SLS printer. This allows them to make a 3D character in software that can be posed and printed repeatedly to achieve stop-motion movement. Among the movies they have made are Coraline, The Boxtrolls, and Kubo and the Two Strings. Since the laser, powder, and quality of these printers need to be quite fine, they are usually very expensive, starting at several thousand dollars for the printer alone.