3D PRINTING

FOR MODEL ENGINEERS

A Practical Guide

3D PRINTING

FOR MODEL ENGINEERS

A Practical Guide

Neil M. Wyatt

THE CROWOOD PRESS

First published in 2018 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2018

Neil M. Wyatt 2018

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 426 1

Disclaimer

Safety is of the utmost importance in every aspect of model engineering. When using tools, always follow closely the manufacturers recommended procedures. However, the author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

Contents

Related Titles from Crowood

CAD for the Workshop

NEIL HUGHES

ISBN 978 1 84797 566 9

112pp, 210 illustrations

Casting for the Home Workshop

HENRY TINDELL AND DAVE COOPER

ISBN 978 1 78500 353 0

176pp, 290 illustrations

CNC Milling in the Workshop

DR MARCUS BOWMAN

ISBN 978 1 84797 512 6

144pp, 280 illustrations

Laser Cutting and 3-D Printing for Railway Modellers

BOB GLEDHILL

ISBN 978 1 78500 226 7208

208pp, 440 illustrations

The Mini Lathe

NEIL M. WYATT

ISBN 978 1 78500 128 4

128pp, 300 illustrations

Workholding for Machinists

TIM STEVENS

ISBN 978 1 78500 238 0

112pp, 120 illustrations

In case of difficulty ordering, please contact the Sales Office:

The Crowood Press

Ramsbury, Wiltshire, SN8 2HR, UK

Tel: 44 (0) 1672 520320

enquiries@crowood.com

www.crowood.com

1 Introducing 3D Printing

Two of the many creative hobbies are focused largely on engineering. Model Engineering, Hobby Engineering or Home Shop Machining has a long and honourable history, chiefly focused on machining metal to make working models, tools and mechanisms. It generally presupposes a well-equipped workshop. Symbolized by a happy driver being hauled along by the miniature locomotive made in his own workshop, it is seen, somewhat unfairly, as a hobby for empty nesters and the retired.

Fig. 1.1: A classic maker innovation, the Pi-Top uses a Raspberry Pi computer to make a fully functional laptop.

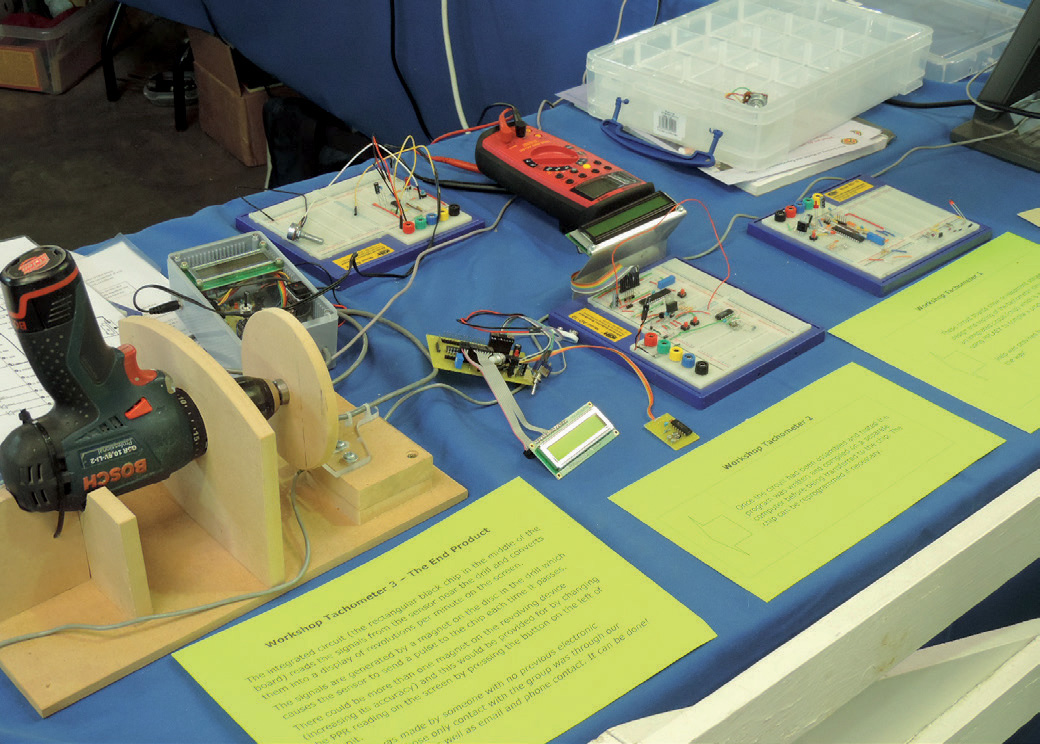

In contrast there is the upstart youth of the Maker Movement. The maker hacks and scrounges from broken mechanisms, works with mysterious electronics and mixes in a liberal dose of special parts like bearings, nozzles and stepper motors. The archetypal maker is a student hunched over a computer screen, programming life into her latest creation. Makers have driven a huge amount of innovation with affordable technologies ().

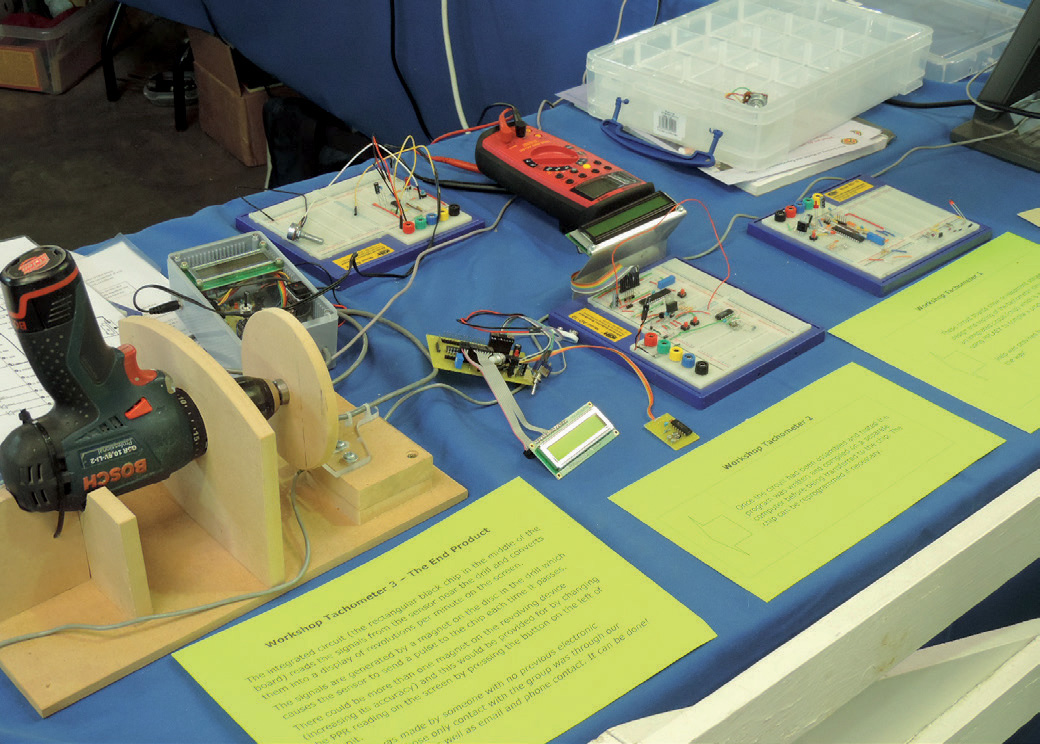

Fig. 1.2: Model engineers can get on with new technologies!

As with all broad generalizations, of course, there may be some truth in this, but it is far from right. There are plenty of youngsters skilled with lathe and mill, and plenty of todays retirees grew up with computers (). And none of them can pick up a part of a broken machine without musing about a new purpose to which it can be put.

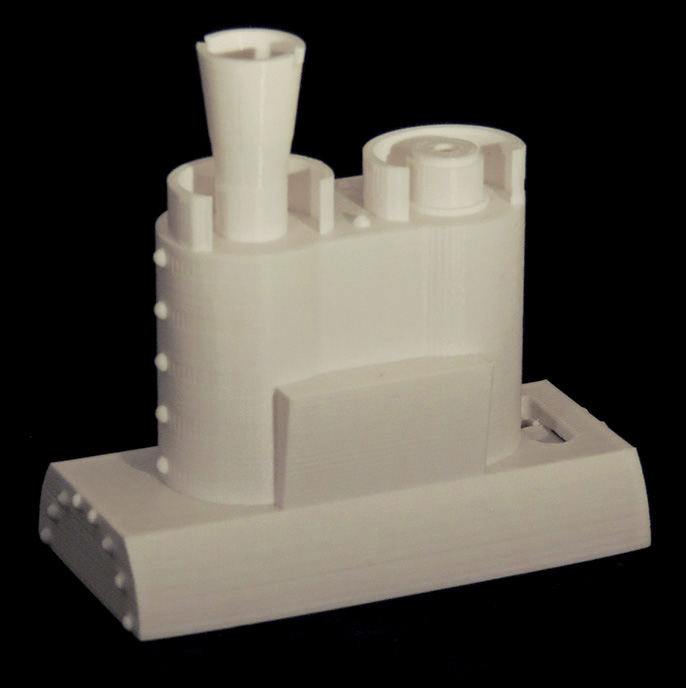

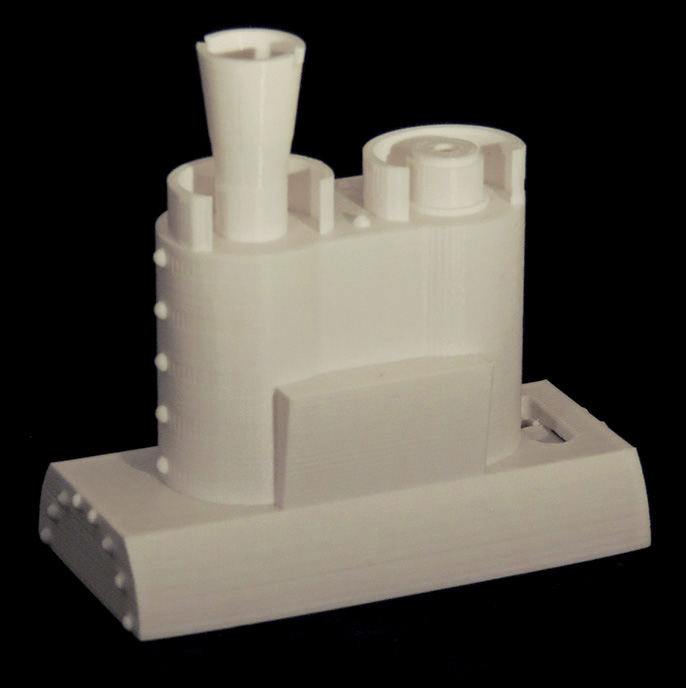

Fig. 1.3: 3D printing can produce very high-quality parts.

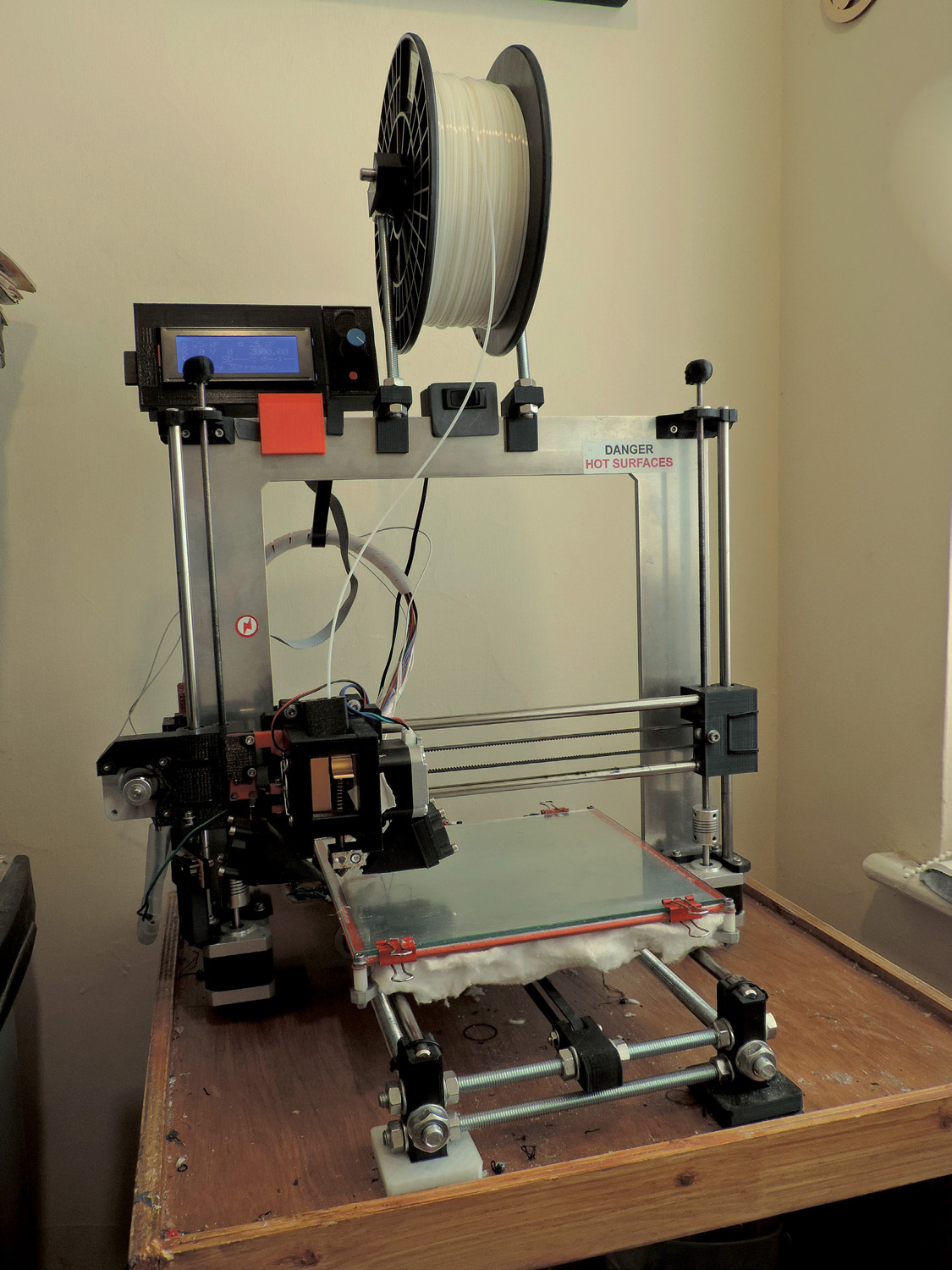

3D printing is where making and model engineering meet head on: designing the parts for your latest project and printing them on your desk is now a practicable possibility as todays 3D printers are serious workshop tools that can make reliable, accurate parts to use alongside those made by traditional methods ().

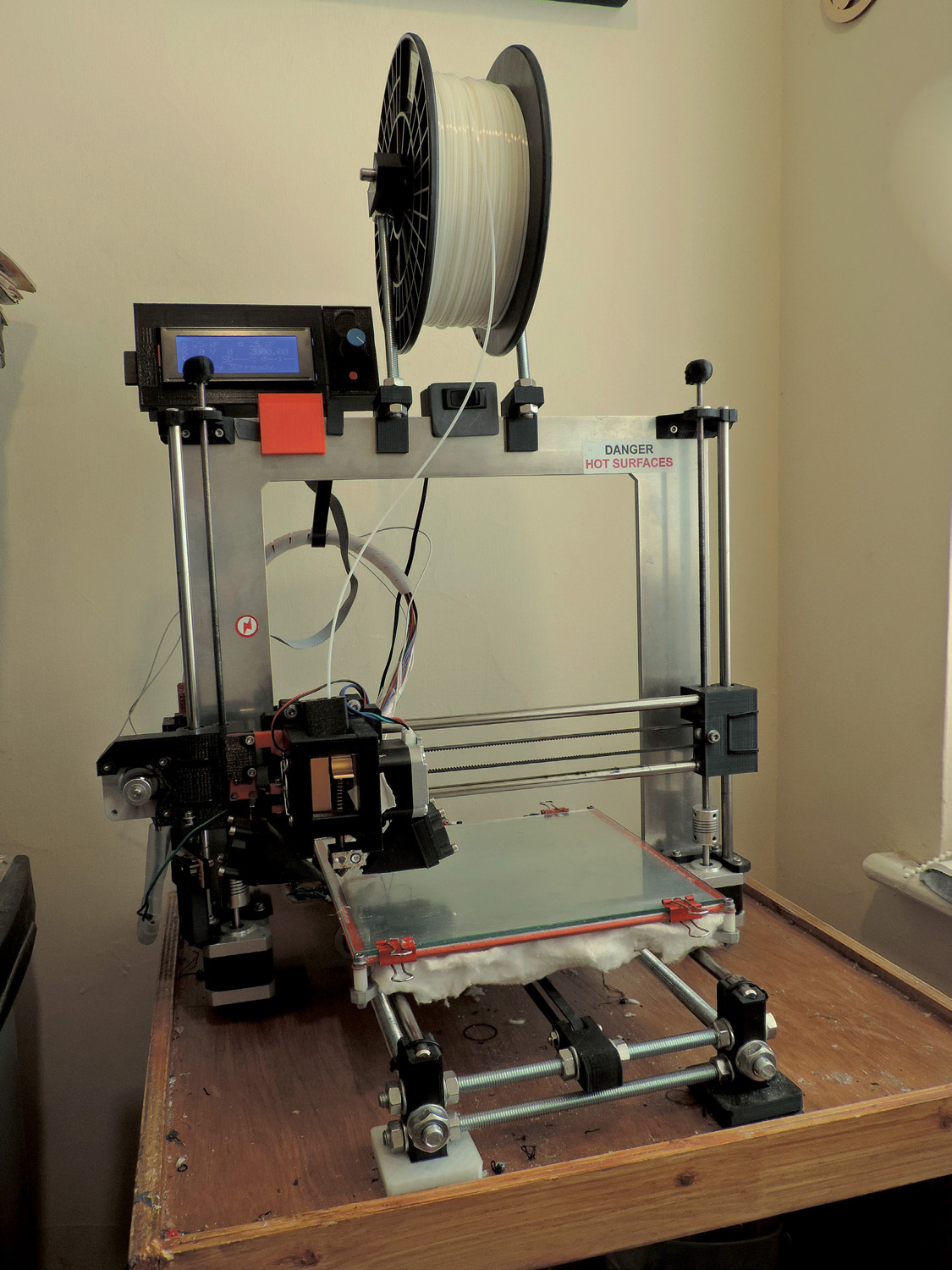

In 2006 Dr Adrian Bowyer and his colleagues at the University of Bath used a RepRapOne Darwin to print the plastic parts that enabled them to make a working replica of it. The idea caught the imagination of makers and model engineers alike. Within five or six years the original RepRap design had been greatly refined, kits of parts were becoming widely available, and consumer printers were coming onto the market. A mere 3070,000 were sold in 2012, but it has been estimated that more than a quarter of a million consumer 3D printers were sold in 2016. No reliable figure can be estimated for the number of kits and complete home-builds produced to complement these.

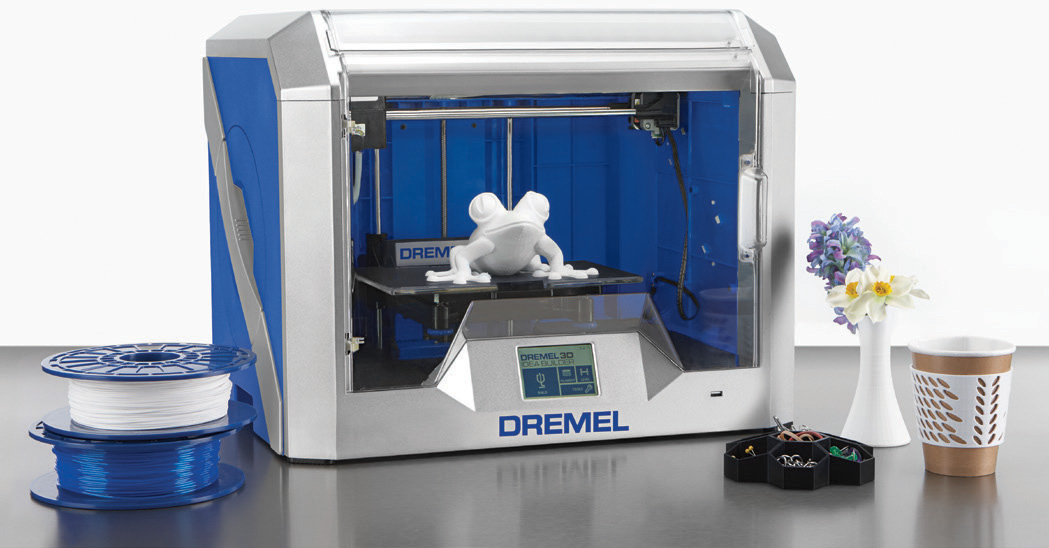

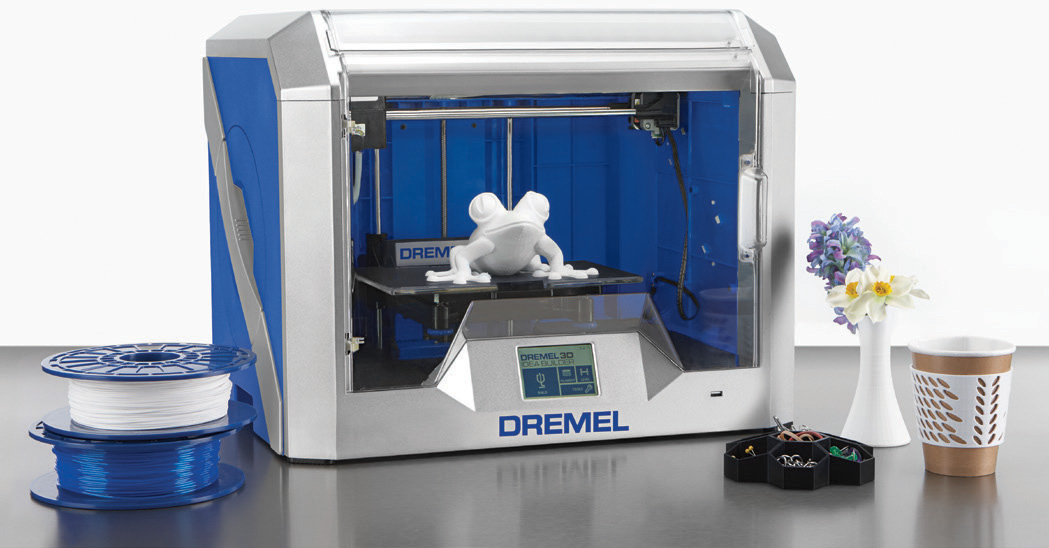

Fig. 1.4: The Dremel 3D40 is an easy-to-use consumer 3D printer popular with schools.

Over this decade the quality and capabilities of entry-level printers has just got better and better. Even inexpensive kit-built machines can work at resolutions approaching those used in a metalworking workshop and use a bewildering range of filaments with a multitude of applications. Reliable, high-quality, off-the shelf printers are now an affordable reality within the grasp of most households ().

Just as it has become commonplace to find milling machines and even Computer Numerical Control (CNC) in hobby workshops, 3D printers are starting to become an essential adjunct to the lathe. This book aims to give both novices and more experienced users a perspective on what these machines can do and how we can make the most of their capabilities, a starting point on the road to realizing the potential of 3D printers in our workshops.

So just what is a 3D printer and how does it work?

Next page