Joan Horvath - 3D Printing with MatterControl

Here you can read online Joan Horvath - 3D Printing with MatterControl full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2015, publisher: Apress, genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:3D Printing with MatterControl

- Author:

- Publisher:Apress

- Genre:

- Year:2015

- Rating:4 / 5

- Favourites:Add to favourites

- Your mark:

3D Printing with MatterControl: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "3D Printing with MatterControl" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

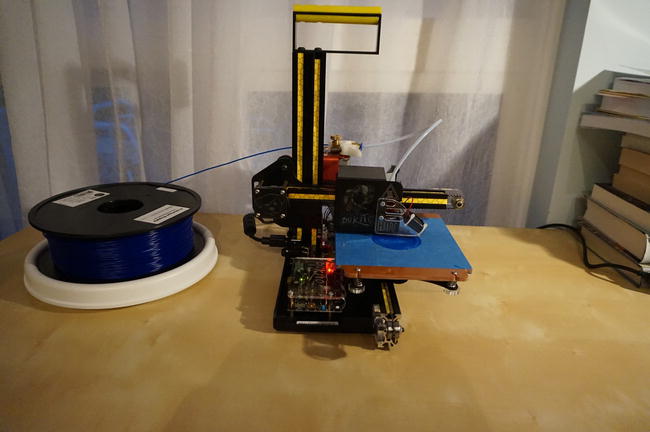

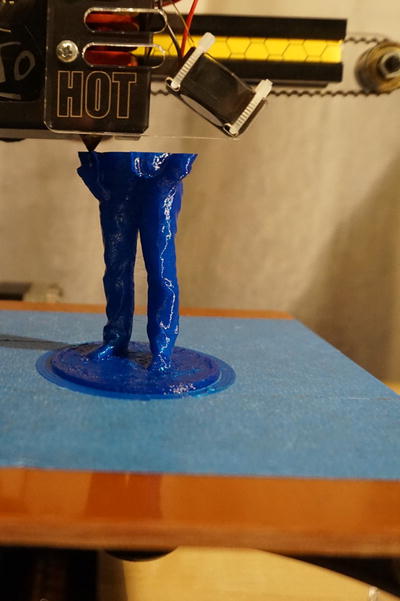

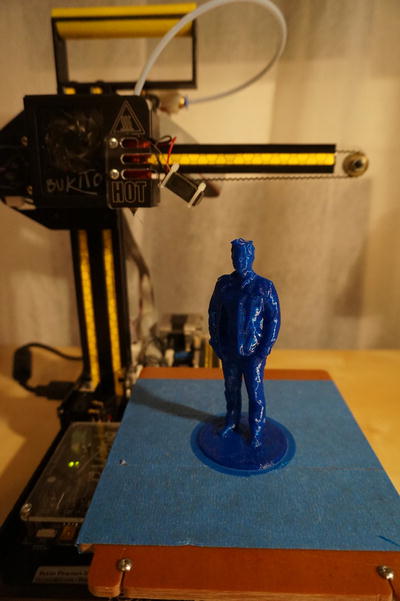

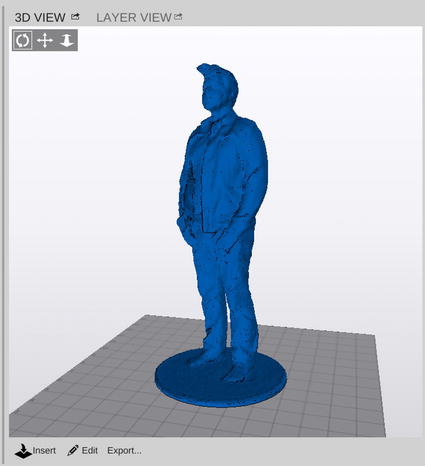

In 3D Printing With MatterControl, Joan Horvath and Rich Cameron, the team behind Mastering 3D Printing, explain step-by-step how to use the MatterControl program, which allows you to control many common types of 3D printers (including both cartesian and delta style machines). 3D Printing With MatterControl can stand alone, or it can be a companion to Mastering 3D Printing to show you how to install, configure, and use best practices with your printer and printing software. The book includes both step by step software walkthroughs and case studies with typical 3D printed objects.

Whether you are a maker or a teacher of makers, 3D Printing with MatterControl will show you how to get the most out of your printer with the new standard for open source 3D printing software.

While there are books available on 3D printers, and even a few on software to make models for printers, there are few good sources covering the software that actually controls these printers. MatterControl is emerging as the leading open source software for 3D printers, and 3DPrinting With MatterControl covers this new standard in this brief book.What youll learn- 3D model basics and slicing the model

- Controlling the printer and using G code

- Working with different materials and different printing situations

- Using MatterControl plug-ins

- Using your 3D printer in the classroom

- Basic post-processing and troubleshooting

Makers, students, teachers, hackerspace leaders, and anyone who wants step-by-step guidance on using MatterControl 3D printer software.

Table of ContentsPart 1: The 3D-Printing EcosystemChapter 1. The Desktop 3D Printer

Chapter 2. What is MatterControl?

Chapter 3. Downloading and Configuring MatterControl

Part 2: The 3D-Printing Process

Chapter 4. Making a 3D Model

Chapter 5. Slicing a 3D Model

Chapter 6. Controlling your 3D Printer

Chapter 7. Material Considerations

Chapter 8. Special Cases

Part 3: Your Printer at Work

Chapter 9. File and Settings Management and the Touch Tablet

Chapter 10. Case Studies and Classroom Tips

Chapter 11. MatterControl Plugins

Chapter 12. Troubleshooting and Post-Processing

Appendix A. Supported Printer Manufacturers

Appendix B. Links

Joan Horvath: author's other books

Who wrote 3D Printing with MatterControl? Find out the surname, the name of the author of the book and a list of all author's works by series.