1. Whats Possible with 3D Printing?

Game-changing , groundbreaking , enabling , and disruptive are just a few of the many words used to describe the growing manufacturing technology known as 3D printing. As an established means of making things (3D printing is more than 30 years old and was conceived by Chuck Hull in 1983), 3D printing is an additive fabrication process that can turn digital computer-generated geometry into physical objects using a variety of materials through a layer-by-layer building process. Because of many recent developments, this amazing process of making things has become a mainstream means of production and is now being utilized by companies large and small, startups, schools, hobbyists, designers, and artists in a wide range of industries.

What makes 3D printing unique among other manufacturing technologies is that it is easily accessible, opening the doorway for anyone, with the desire, to turn their ideas into physical products, parts, tools, and works of art. Part of this accessibility can be found in a range of online services that allow those interested to peruse and output 3D-printable content. As a valuable resource, the Web is a grand showcase of 3D-printable objects, sculptures, and parts waiting to be discovered. With nothing more than an Internet connection, access to 3D-printable content is only few clicks away, making it is easy to download and purchase 3D-printable products.

Yet, while anyone can access 3D-printable content online, eventually aspiring 3D designers will want to create 3D-printable objects of their own. Thankfully, with the wide range of free modeling software tools available, there are many opportunities for designers from all walks of life to begin the modeling process. While, some may be more comfortable with jumping right in and exploring on their own, others might be overwhelmed by the many tools and techniques available. Therefore, for those who want a deeper insight on where and how to get started, this book, Beginning Design for 3D Printing , has been written to cover a wide range of design and modeling techniques for 3D printing.

Through the course of this book you will be introduced to step-by-step design techniques to build up modeling skills for 3D printing. Since this book follows the belief that 3D printing should be accessible to everyone, the workflows presented will take advantage of a broad range of 3D software tools that are freely available online. Some of the software tools introduced have intuitive interfaces and are easy to learn. A few 3D tools will be a bit more complicated, but since this book is using a pathway approach to educate, new users should have no problems if they begin their journey with the basic 3D modeling methods presented in the early chapters and then proceed along the path to learn more intermediate and advanced techniques presented in the later chapters. More seasoned modelers may find this book to be a handy reference as well since it will touch upon a variety of methods for generating 3D structures along with providing different ways to validate files to ensure success in the 3D printing process.

Before I begin discussing the modeling process for 3D printing, this initial chapter will provide a glimpse into the growing list of objects, structural forms, and products being created with the 3D printing process. If you are completely new to 3D printing, this chapter will provide you with an overview of what is possible and inform you of the growing trends shaping 3D printings continuing evolution. Knowing what is and isnt possible will help you get a firmer understanding of what 3D printing is capable of and ideally will provide you with the confidence that your own ideas and designs are 3D printable. The many 3D-printed objects and trends featured in this first chapter will let your own imagination take flight as you begin the journey into the world of design for 3D printing.

Enter a New Era of Design with 3D Printing

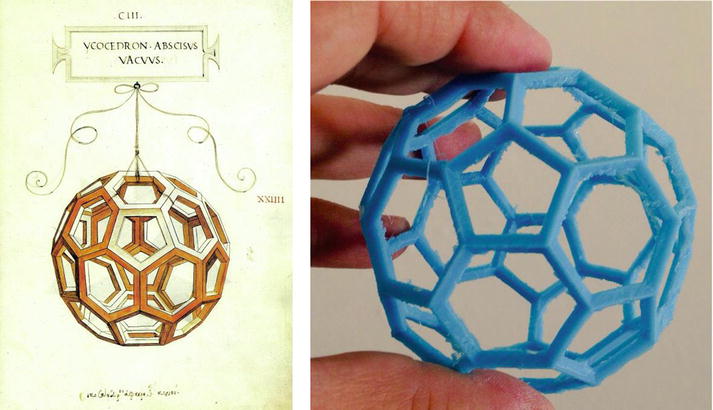

The motivation to be creativethe spark of ingenuity that motivates us to design, craft, construct, and manufactureis a basic human desire. Like Leonardo da Vinci, many of us have, in the back of our minds, a blueprint for an amazing idea, a working machine, or a beautiful piece of art. (In fact, many modern-day designers have 3D printed some of da Vincis original illustrations, as shown in Figure .) Our desire to build and create is no different from the motivation that inspired great artists and engineers to bring the marvels of civilization into existence. Every day, a new concept is born in countless imaginationsideas for products and things that would make the world a better place. Yet, we often cast such plans aside with the perception that they would be too complex, costly, and time-consuming to build. Self-doubt often sets in, and our most practical plans get thrown into the bin of abandoned dreams.

Figure 1-1.

An original illustration of a polyhedral structure by Leonard da Vinci and a 3D-printed version created in Blender and printed using Deezmakers Bukito 3D printer

But now 3D printing has made the inconceivable possible: the transformation of our digitally dreamt-up ideas into multidimensional reality. Through this growing 3D-printing phenomena, many barriers of production can be overcome, enabling the artist, designer, and manufacturer in all of us to bring our ideas into fruition. With this remarkable digital technology, a new world of fabrication awaits where anybody can turn computer-generated models into real-world objects. In schools, libraries, community spaces, local businesses, and online, many da Vinci dreams are now becoming 3D-printed reality.

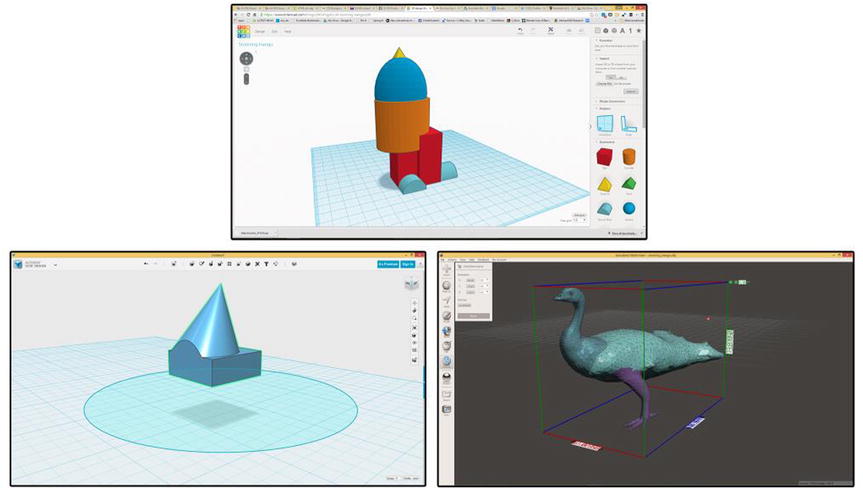

As someone reading this book, youve probably developed an interest in 3D printing and are eager to take advantage of this incredible technology. But a 3D-printed product or work of art is only as good as the design put into it, and poorly conceived designs cost time and money. To harness 3D printings true potential, a proficiency in design is extremely important. The excitement of 3D printing quickly fades when the final output fails to live up to its initial promise. Having the design skills to model objects for 3D printing is no trivial matter, and unfortunately, with the many software tools available, there is no single design solution to create a 3D-printable product. New, eager designers are faced with an overwhelming number of techniques to learn, which include spline-based modeling, polygonal box modeling, digital organic sculpting, parametric workflows, high-precision solid modeling, and even a bit of computer programming. Thankfully, many free 3D modeling programs are available that will allow a new designer to gradually learn the 3D modeling process. Open source applications and easy-to-learn software tools such as FreeCad, OpenScad, Tinkercad, 123D apps, Microsoft Builder, Blender, and Sculptris (Figure ) allow eager designers to become familiar with the necessary basics (such as navigating 3D space and combining geometric shapes) to build simple objects that will enable them to start printing their own customized 3D objects.

Figure 1-2.

Free applications from Autodesk (Tinkercad on top, 123D Design at the lower left, and Meshmixer at the lower right) can help newcomers learn 3D modeling skills right away