ACKNOWLEDGMENTS

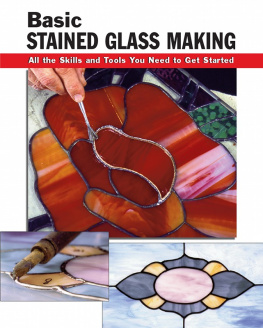

FOR MANY YEARS , the original version of Basic Stained Glass Making has been a great resource for all of us at Rainbow Vision Stained Glass. It was a pleasant surprise when I was asked to revise the book and update the projects. Many thanks to Mark Allison and Judith Schnell of Stackpole Books for the opportunity to work on this with them.

My deepest appreciation to my daughter, Katie. She has worked side-by-side with me through every step in creating the revised book, and she has designed each of the new projects presented. Without her keen artistic ability and organizational skills, the revised book would not have as polished an appearance.

A very special thank you to Alan Wycheck of Alan Wycheck Photography in Harrisburg, Pennsylvania. His eye for capturing an image from just the right angle, with exactly the right lighting, is exceptional. I appreciate his dedication and expertise while collaborating on this project with us.

The staff at Rainbow Vision has been great while I have been working toward completion of this book. Lee Summers, Jan McKelvey, Lou Ann Benedict, Melissa Flood, and, again, Katie Haunstein have all been very helpful and supportive. They have been wonderful with hands-on assistance and as advisors whenever I needed their help. They are the best!

And last, but never least, my gratefulness to my husband Jim and my family and friends. Your complete support throughout the revision process was wonderful. Thank you.

Lynn Haunstein

RESOURCES

Rainbow Vision Stained Glass, LLC

3105 Walnut Street

Harrisburg, PA 17109

www.rainbowvisionsg.com

Rainbow Vision offers a large array of stained glass and fused glass classes and carries a complete line of tools, supplies, equipment, and sheet glass from a variety of manufacturers. Custom design and stained glass panel construction as well as glass repairs are also offered.

Retailers of Art Glass and Supplies (RAGS)

www.stainedglassretailers.com

RAGS is a nonprofit organization of retail store owners with members from across the United States and around the world. Use the Store Locater function on the website to find a retail stained glass store near you!

Stained Glass Association of America (SGAA)

255 Pratt Street

Buffalo, NY 14204

www.stainedglass.org

SGAA is a professional trade association working to elevate the art of stained glass through classes and product development. For more than a century, SGAA has maintained historical archives, provided a wealth of information to its members, and continues to advance the craft of stained glass.

Alan Wycheck Photography

331 South Front St.

Harrisburg, PA 17104

alan@alanwycheckphoto.com

www.alanwycheckphoto.com

GLASS MANUFACTURERS IN THE UNITED STATES

Bullseye Glass Company

3722 SE 21stAve.

Portland, OR 97202

www.bullseyeglass.com

Kokomo Opalescent Glass

1310 S. Market St.

Kokomo, IN 46902

www.kog.com

Oceanside Glass & Tile

5858 Edison Place

Carlsbad, CA 92008

www.glasstile.com

Paul Wissmach Glass Company, Inc.

420 Stephens St.

Paden City, WV 26159

www.wissmachglass.com

Youghiogheny Opalescent Glass Company

300 S. 1st St.

Connellsville, PA 15425

www.youghioghenyglass.com

Also available from Stackpole Books

Beyond Basic Stained Glass Making

40 Great Stained Glass Projects

Making Stained Glass Boxes

Making Stained Glass Lamps

Making Tiffany Lamps

Basic Glass Fusing

40 Great Glass Fusing Projects

CREATING A GOOD WORK ENVIRONMENT

IF YOU ARE JUST BEGINNING TO WORK WITH STAINED GLASS , you will want to set up a dedicated work area. Your first concern should be a table or work bench that is a comfortable height to stand beside while cutting glass. Our tables are about 36 inches high, but find a height that works best for you.

It is not a good idea to cut glass on a hard wooden or metal surface. Look for a surface that will cushion the glass while you cut. In our photo, the gray surface is a Homasote board. This substance is made from recycled materials by the Homasote Company in West Trenton, New Jersey, and can be purchased at certain building supply centers. It is a firm surface but has just enough spring to it to allow for successful glass cutting. Push pins and nails can be used with the surface to hold projects together. Homasote is also a fire-resistant material, which makes it a great surface for soldering your projects. A section of Homasote can be used over and over again before needing to be replaced.

You will want to set up your work area where creating glass debris and using chemicals will not pose a risk to others. Children and pets should not have access to your work area for obvious safety reasons.

You may be using lead-based solder and framing materials while working on stained glass projects. Adequate ventilation in your work area is important for working with metals and chemicals used in the stained glass process. Refrain from eating, drinking, or smoking in your work area.

A good light source in your work environment is important. Make sure you have adequate light for all aspects of stained glassfrom cutting the pattern through the polishing steps.

While working with stained glass, you will be producing chips and shards of glass. Frequent use of a brush and dustpan will keep your work area safer. A hand-held vacuum can also be a good way to clear glass debris from your work space.

A handy water source is an asset to any work area. This can be either running water from a faucet or water brought to your work space in basins. You will need to wash your glass pieces, wash chemical residue from your projects, and wash your hands often. Old towels are great for drying the projects or glass. You will want to have several of these nearby.

You will need an electrical source for any tools that require power, such as a soldering iron, an electric grinder, a vacuum cleaner, and any other power tools that may come in handy.

Consider how you will store your sheets of stained glass. They should be stored vertically for easy access, and for their safety. If you choose to lean glass against a wall, use something like cardboard under the glass to protect it from a hard floor surface. Old milk crates can be used to store small sheets of glassagain, store the glass vertically. Flat stacks of glass on a floor or table surface can be subject to breakage.

You will begin to accumulate a number of small hand tools as you develop your glass craft. A toolbox or caddy will be very useful to store these tools and keep them handy. The layout of your work area will develop as you discover which tools you use most often.

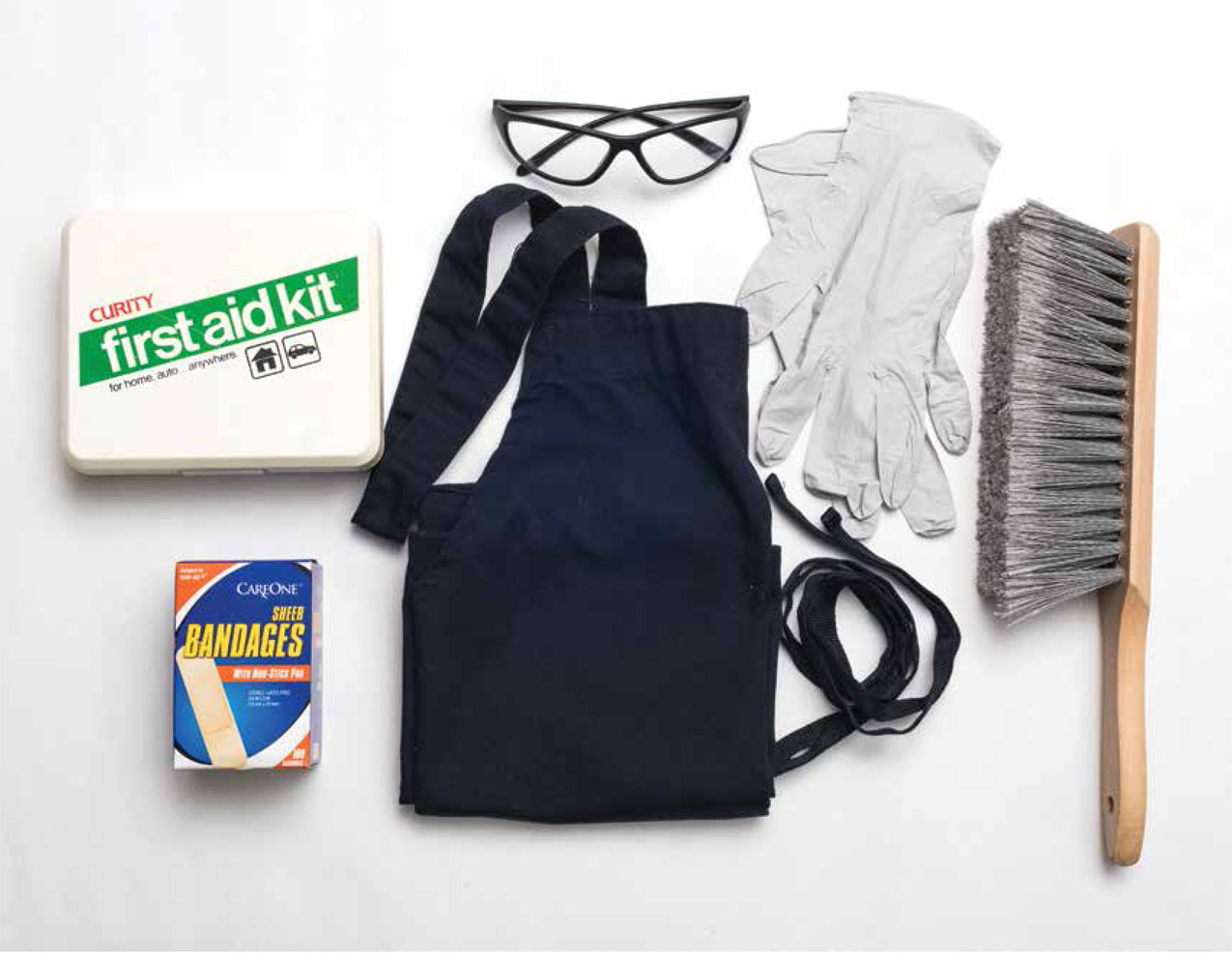

STAINED GLASS SAFETY

IT IS IMPORTANT TO KEEP YOUR SAFETY IN MIND when working with stained glass! Stained glass making requires your full attention. If you are tired or distracted, wait for a time when you can fully focus on your project. Remember that glass has sharp edges, and always handle it with care. Frequently use a bench brush to sweep glass shards away from your work surface and into a trash can. This will help reduce the risk of getting small cuts from debris. Never brush your hand across your work surface, as you will certainly nick yourself!