CarTech

CarTech, Inc.

39966 Grand Avenue

North Branch, MN 55056

Phone: 651-277-1200 or 800-551-4754

Fax: 651-277-1203

www.cartechbooks.com

2014 by Larry Shepard

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without prior permission from the Publisher. All text, photographs, and artwork are the property of the Author unless otherwise noted or credited.

The information in this work is true and complete to the best of our knowledge. However, all information is presented without any guarantee on the part of the Author or Publisher, who also disclaim any liability incurred in connection with the use of the information and any implied warranties of merchantability or fitness for a particular purpose. Readers are responsible for taking suitable and appropriate safety measures when performing any of the operations or activities described in this work.

All trademarks, trade names, model names and numbers, and other product designations referred to herein are the property of their respective owners and are used solely for identification purposes. This work is a publication of CarTech, Inc., and has not been licensed, approved, sponsored, or endorsed by any other person or entity. The Publisher is not associated with any product, service, or vendor mentioned in this book, and does not endorse the products or services of any vendor mentioned in this book.

Edit by Paul Johnson

Layout by Monica Seiberlich

ISBN 978-1-61325-209-3

Item No. SA336

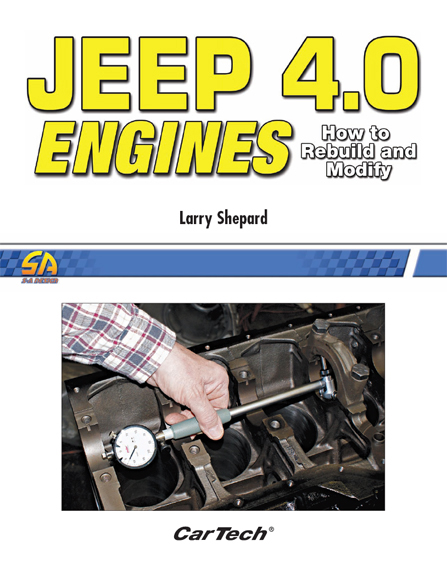

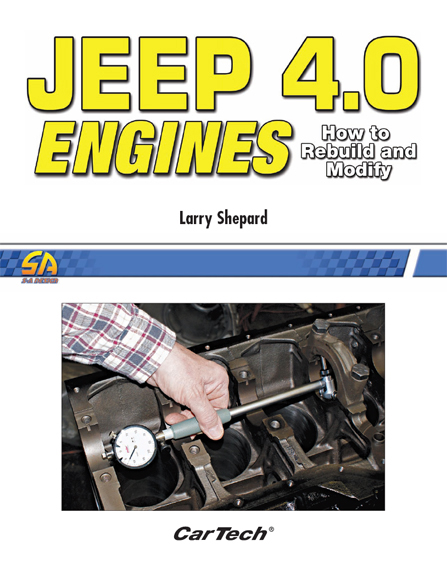

Title Page: The 4.0 engine has 7 main bearings for 6 cylinders while a typical V-8 has 5 mains for 8 cylinders. In a normal rebuild you do not need to line-bore the main bearing bores or replace the main caps. Use a dial-bore gauge to measure diameters. Main cap should be torqued.

Back Cover Photos

Top Left: The first step in the rebuild process is pulling the engine from the chassis. Once the engine is free of the transmission, the engine assembly can be lifted upward. Be very careful and check on all sides to be sure nothing is still attached to the engine.

Top Right: In this step the fuel rail is removed from the intake. A socket and extension and a long-handled ratchet removes the attaching bolts. At engine disassembly, the intake manifold can be removed without taking the fuel rail off or the injectors out.

Middle Left: To determine compression ratio and estimate torque, you need to measure the combustion chamber depth before and after milling. There is no specification on the actual depth of the chamber. Using a depth micrometer, measure the depth to this flat spot before any machining is done.

Middle Right: You need to be sure the engine timing is correct. Install a dial indicator over the top of the #1 piston with the pointer perpendicular to the piston. You need to determine valvetrain operation and that the cam is properly phased.

Bottom Left: Install the main bearing cap, shell and Plastigage onto the proper main journal. Install the main cap bolts and tap cap into place. Be sure that the cap is fully seated and then snug the bolts. Torque the main cap screws to 80 ft-lbs.

Bottom Right: Select a main cap and main bearing shell and insert the main cap bolts. Oil the shell and the threads on the ends of the two bolts.

CONTENTS

The creation of an engine book is a fun project and the photography and writing that are required makes for a very big project. There are lots of parts for V-8 engines but I expected the Jeep inline-6 parts to be rare. I was wrong, however, and lots of research led to lots of parts and not just service parts.

The parent companies AMC and Chrysler built millions of these engines and Joe Hilger and friends got the 4.0 off to a good start but since then the parts leaders have been the aftermarket manufacturers. These manufacturers display their new hardware at events and shows, such as PRI and SEMA, and their representatives are always willing to answer questions and discuss the latest hardware. Thanks to all of these people for their time and patience along with the many racers, off-roaders, and engine builders who have contributed to the Jeep inline-6 program over the past 40 years.

I owe a lot to the late Greg Reeves, Justin Reeves, Tom Habercamp, and Larry Johnson, true Jeepers all, for helping me understandits a Jeep Thing!

Extra special thanks to Rob Cunningham of Mancini Racing, Richard Simon of State Motor, and Bob McSwain and Rob Miela of Godfather Racing for all of their help. I couldnt have done it without them.

And I owe a great deal to my editor, Paul Johnson, who made all this stuff fit into a readable book, for his patience, guidance, and foresight in putting together this inline-6 project.

Special thanks to my wife, Linda, for her patience with the ever-mounting piles of research material, special tools, and tons of photographs, as well as her steady hand in keeping our household going during this project.

This book covers the complete 4.0 engine rebuild project: removal, mounting, disassembly down to the bare block, and reassembly into a complete engine. In an engine project, many procedures could be done at disassembly (see ).

I have therefore discussed specific procedures in detail in the most pertinent chapter rather than bunch them all together. For example, cams are defined in .

The 4.0 inline-6 engine has a very good reputation for dependability and durability. Its generally considered indestructible, a good feature to have if you are going to rebuild an engine. The typical criteria for judgment and comparison of engine durability is mileage, and the project vehicle had more than 219,000 miles on it. Often you would expect a high-mileage engine to yield broken or badly worn parts, but the project engine did not have any broken parts, just normal wear. You want to attribute this to the engine being well maintained.

Next page