CarTech, Inc.

39966 Grand Avenue

North Branch, MN 55056

Phone: 651-277-1200 or 800-551-4754

Fax: 651-277-1203

www.cartechbooks.com

2014 by Paul Cangialosi

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without prior permission from the Publisher. All text, photographs, and artwork are the property of the Author unless otherwise noted or credited.

The information in this work is true and complete to the best of our knowledge. However, all information is presented without any guarantee on the part of the Author or Publisher, who also disclaim any liability incurred in connection with the use of the information and any implied warranties of merchantability or fitness for a particular purpose. Readers are responsible for taking suitable and appropriate safety measures when performing any of the operations or activities described in this work.

All trademarks, trade names, model names and numbers, and other product designations referred to herein are the property of their respective owners and are used solely for identification purposes. This work is a publication of CarTech, Inc., and has not been licensed, approved, sponsored, or endorsed by any other person or entity. The Publisher is not associated with any product, service, or vendor mentioned in this book, and does not endorse the products or services of any vendor mentioned in this book.

Edit by Paul Johnson

Layout by Chris Fayers

ISBN 978-1-61325-211-6

Item No. SA338

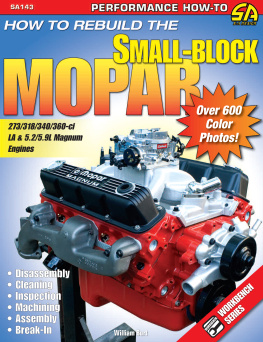

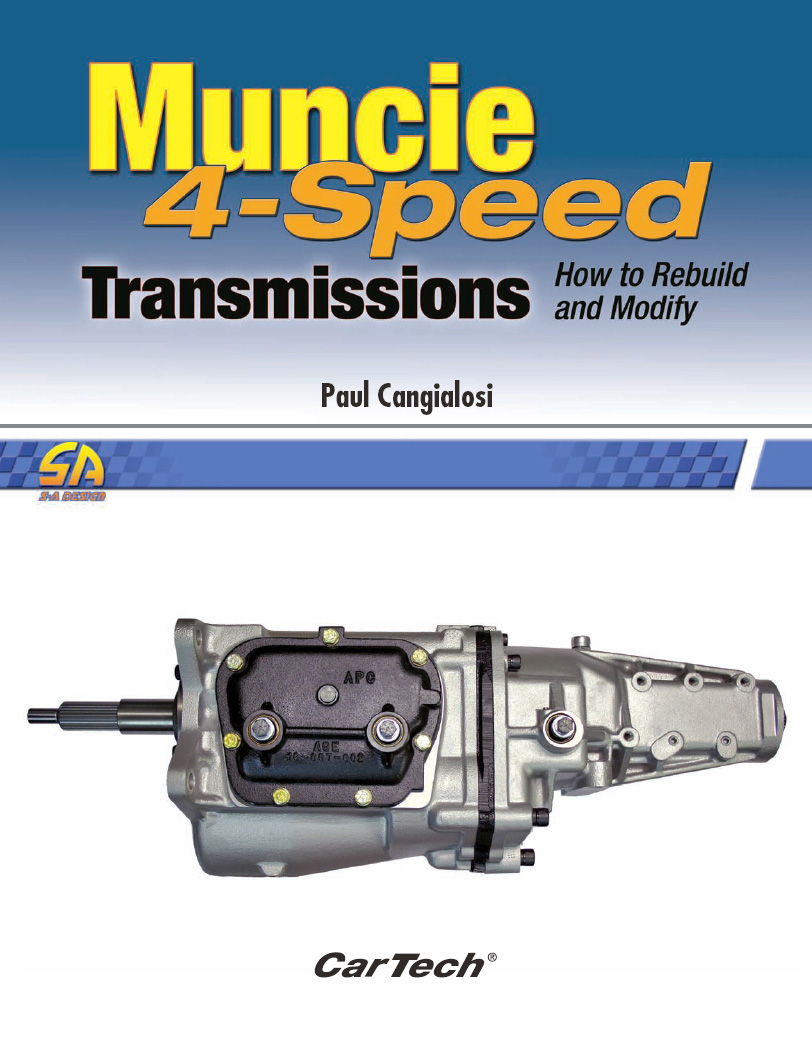

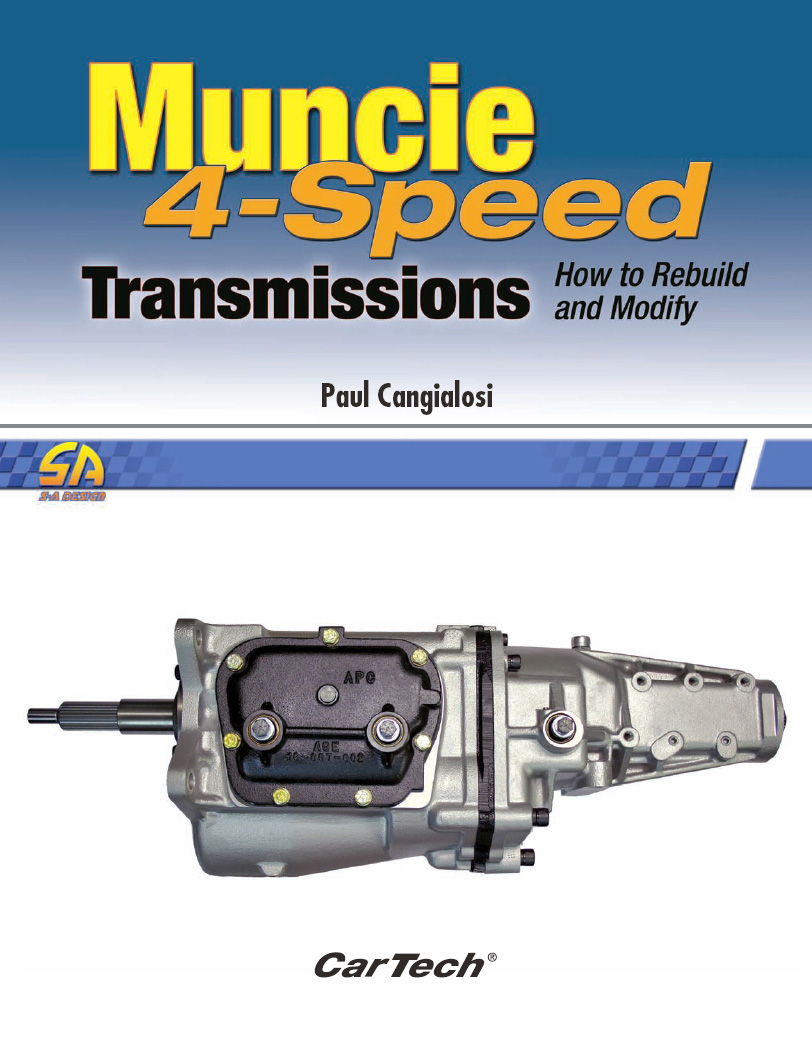

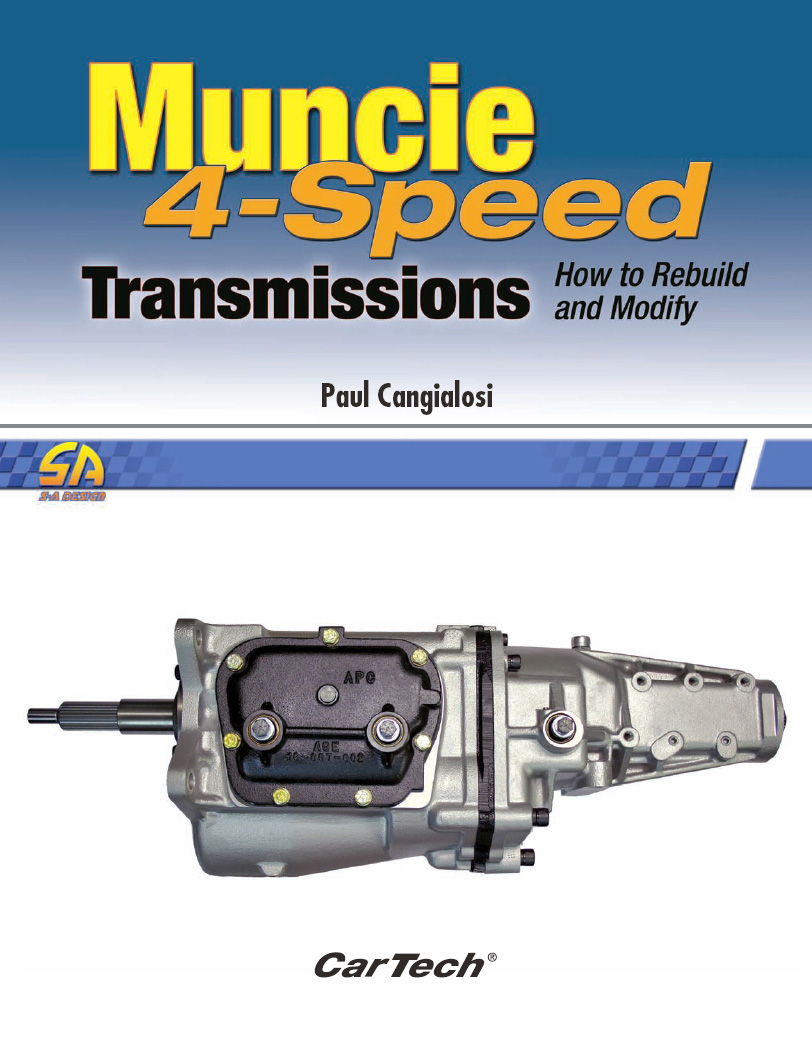

Front Cover:

State-of-the-art replacement Muncie case components and gears set a new standard for rebuilding an old, worn-out Muncie 4-speed.

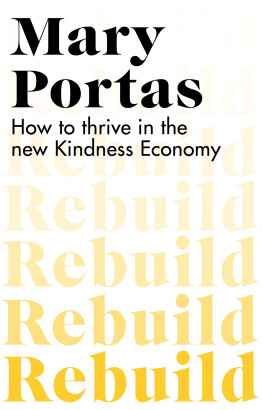

Title Page:

This is a completed SPEC-25. The special Teflon coating reduces internal friction and heat: The exterior becomes a non-stick surface and gasket surfaces clean up very quickly. Plans are in the works for new-style NASCAR synchro assemblies and more ratios, so a SPEC-35 will most definitely be in the future!

Back Cover Photos:

Top

Usually the gear and 3-4 synchro hub dislodge if you hold third gear and gently tap on the front of the mainshaft. Later units have hardened hubs with extremely tight press fits, and you must use a press to remove them. If the gear and hub do not come off, do not use a hammer to try to remove them. The tip of the mainshaft is easily damaged. Use a press and bearing clamp on third gear for removal.

Middle:

Lift the countergear out of the case. If the case was damaged from a gear explosion, the thrust washers are often jammed from debris. If that has happened, stand the case on its front face, so that the loose gear doesnt cock or move off center, and rotate it as you remove it.

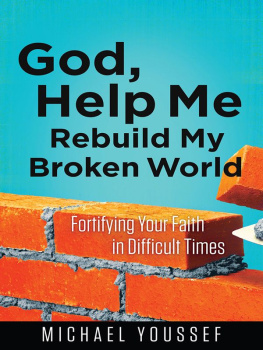

Bottom Left:

The bronze synchro ring has a 6-degree internal taper that matches the taper on the gears synchro cone. As it is forced up against the cone, it eventually causes the output shaft to run at the same speed as the gear. Its essentially a cone clutch.

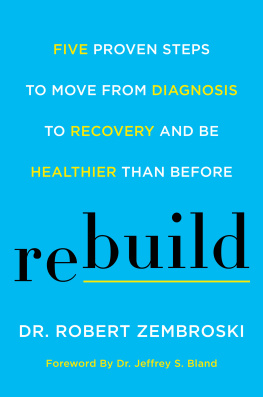

Bottom Right:

I never press directly on gear surfaces. The lower gear has an old bearing race against it. This grabs closer to the inside diameter of the gear to prevent press-surface contact with the gear teeth.

CONTENTS

When CarTech offered me a contract to write a book on Muncies I thought to myself that it is something I do every day, and it will be an easy task. Wrong! It took longer than anticipated. I had many setbacks, both on a personal and a business level. Id like to thank my editor Paul Johnson and CarTech for their support and belief in me.

Brian Higgins of the SK Tranny Shop allowed me to crawl around his parts photographing some archeological finds. His place was mind blowing as usual. Thank you, Brian, for allowing me to interrupt your busy schedule.

Larry Fischer, a true legend and a long-time friend, also took some time to drag out parts and talk about his experiences.

Ed Hartnett was instrumental in sending me pictures of his rare 3864848 cases. I thank him for putting up with my nagging to get the perfect shot.

George Sollish of Auto Gear is the man responsible for bringing back the Muncie. Id like to personally thank him and his hard-working staff: Robin, Matt, Nathan, Billy, Howie, Joe, and the cats. Without them there would be no future for this transmission and Id still be playing drums in some crappy punk-rock band.

The late James Fodrea, who was credited for the design of the Muncie, gave many others and me a career in manual transmissions. I give sincere thanks to his daughter, Joan Fodrea Cooper, for taking the time to talk about her father and his days at General Motors.

My biggest realization in writing this book came from seeing how unorganized my shop really is compared with everyone elses. My webmaster, Janet, aka Gear Rhonda, still makes it a point to insult me every day in front of hundreds of web clientele. She inspires me to continue to push myself and set unrealistic goals.

Cristina, one day all this will be yours!

You have purchased this book because you want to learn about the Muncie 4-speed. I was chosen to write this book because I have been involved with rebuilding, manufacturing replacement parts, and selling completely new replacement 4-speed Muncies for 34 years.

Writing this book has been an interesting journey and I have met a lot of people along the way. One thing that I must point out before I start going into technical details is that if not for all the people I met buying, selling, rebuilding, and manufacturing parts for these transmissions, I probably would not have been in this line of work. Many people have transitioned their love for Muncies into viable businesses, or in some cases, great supplementary income. The Muncie was used in GM vehicles from 1963 to early 1975. The number of these transmissions is staggering. Hundreds of thousands of Muncie 4-speeds were produced and no other 4-speed in the world comes close to those numbers.

In 1979 I was one of those hobbyists. I purchased loads of Muncie cores at local car shows and started rebuilding them with parts scavenged from other transmissions. I purchased inventory from auto parts stores that were liquidating new gears. In those days, junkyards used to rebuild transmissions with cores they had on hand. It was the same thing I was doing, except they had a lot more space and inventory. When these businesses got out of rebuilding, I ended up purchasing their inventory and new parts. I had acquired a few hundred Muncie transmissions and loads of parts. I also had Ford and Mopar transmissions but, honestly, the demand was just not there at that time. Because these transmissions were relatively untouched I got to see the pattern of how they were put together. For example, I learned how certain case components were mated to other parts and what type of bolt logos were used during certain years.

A few Corvette collectors contacted me about authenticating their transmissions. I recall they were 1963 and 1966 Z06 Big Tank cars. I started rebuilding transmissions for a number of Corvette collectors and shops during that period. One owner suggested that I go to the Corvettes at Carlisle show and sell my rebuild kits to the public. At the time I had a fulltime job as a mechanical engineer and never really sold at car shows; I was always buying. I did notice that nobody was selling anything new. Typically, most used parts were laid out on a blanket, unclean, and with some price sticker on them. There was endless used stuff around but nothing available new for sale to repair or to rebuild these transmissions.

Next page