First published in 2013 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

George Dent 2013

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978-1-84797-646-8

CONTENTS

ACKNOWLEDGEMENTS

For help with materials, tools and kits, my thanks go to Alex, Lisa and the team at The Airbrush Company; Geoff Baxter (The Hollywood Foundry); Charlie Petty (DC Kits); John Bristow (Deluxe Materials), Peter Harvey (PH Designs); Brian Hanson (Shawplan) and Dave Alexander (Alexander Models).

At Model Rail magazine, Ben Jones, Richard Foster and Chris Leigh have been very helpful, and Dave Lowerys expertise in all things metal has proved invaluable. Thanks also go to Chris Nevard for the kind use of his photographs, and I am indebted to Jimmy Lavery for the continued use of his Waytown layout as a backdrop-cum-test track, and for a number of his photographs.

Jeanne Carrs cottage in Settle has again proved the perfect place to thrash out a manuscript, and I have greatly appreciated the donation of a number of metalwork tools from my father-in-law: these have come in very useful during the many projects contained in this book thanks, David! Finally, special thanks go to all members of the Dent Collective, human and animal. Keep the red flag flying

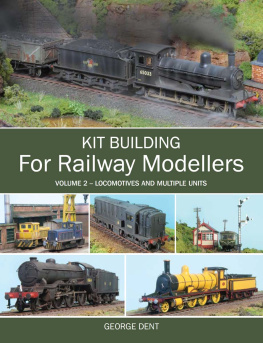

Locomotive kit building can be as humble or grandiose as you like. Cutting your teeth on a humble subject, such as this plastic diesel shunting loco, is a great way to learn a number of vital skills, including accurate assembly of a chassis, installing a working power unit and creating a realistic paint finish.

PREFACE

Pride may be one of the seven deadly sins, but there is little to match the hubris of watching a kit-built vehicle moving smoothly around the layout under its own power. Better still if it is finished to a realistic standard, perhaps with a decent weathering job or carrying some intricate detailing that wasnt part of the original kit. And if its something grand such as a steam engine, with working connecting rods and valve gear, then its hard not to let the sense of achievement overwhelm you.

Pride in your handiwork is nothing to be ashamed of indeed, I dont think I need be banished to Dantes Inferno to learn humility. In fact, Im more than happy to admit that Im nowhere near the best and certainly not the most prolific loco kit builder there has ever been. Nor will I ever be; Im still in this hobby for the fun and enjoyment, as well as the chance to keep learning new things.

On the other hand, I do get through a good few kits every year, of varying materials, scales and difficulty. Whats more, many of the projects are of other peoples choosing, which has proved a great way to learn. If it had been up to me, there are a number of past projects that I would never have undertaken, contenting myself with the easier, quicker or cheaper routes. But forcing oneself to take the plunge and see where the waters take you can be an instructive and interesting journey.

So why not have a go, perhaps starting with something simple like a single-piece plastic body and a ready-made power unit. Then move on to something a little more taxing, such as a multiple unit with articulated bogies and an interior to think about. From here, we can integrate new skills such as soldering or shaping sheet metals in terms of detailing parts. The next logical step is to try building up a new brass chassis for a tender, learning how to get the axles aligned and the parts sitting squarely together. Its only a small step from here to building a powered chassis. Tackled in small steps, rather than grand leaps, there shouldnt be anything too intimidating about the next stage.

ABOUT THE AUTHOR

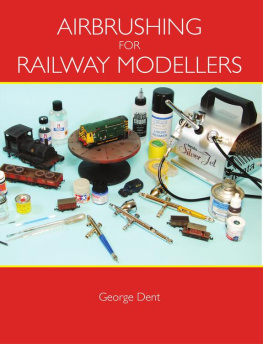

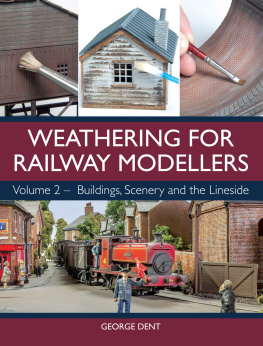

Formerly a graphic designer, guitar maker and museum conservator, I have been the in-house model maker at Model Rail magazine since 2004. In that time I have produced countless articles, run courses on airbrushing and weathering, as well as appearing in instructional DVDs. My four previous titles for Crowood include Detailing and Modifying Ready to Run Locomotives in OO Gauge, Volumes 1 and 2; Airbrushing for Railway Modellers; and Kit Building for Railway Modellers, Volume 1.

INTRODUCTION

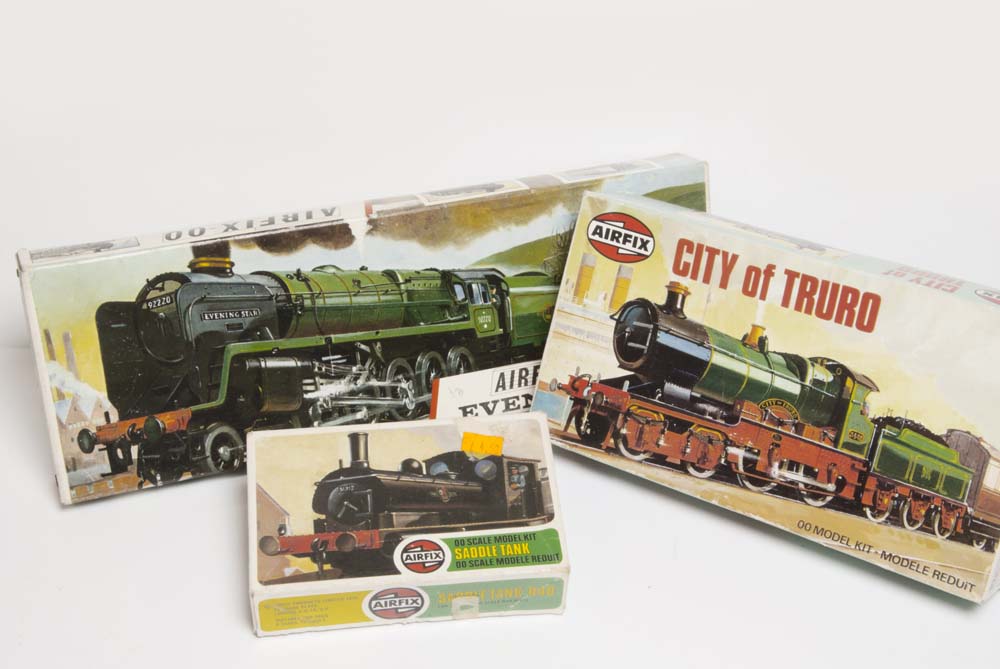

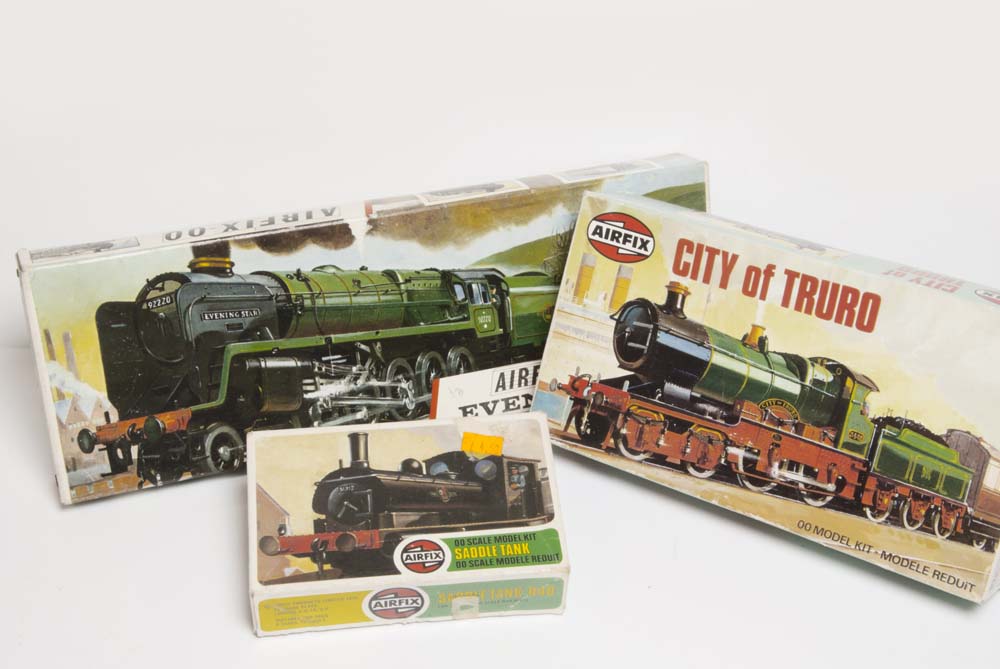

Mine has been a long and enduring love affair with model railway kits. Beginning with the iconic Airfix brand, they offered a cheap yet priceless means of honing essential modelling skills, such as assembly, customization, painting and weathering. Indeed, the experience proved hugely addictive: once Id built the first plastic wagon kit, I was instantly hooked. The passion remains, all these years later, with ready-to-run (RTR) rolling stock still ranking below kits as far as enjoyment is concerned.

As for locomotives and multiple units, kits have also played a large part in my modelling career. Diesel multiple units (DMUs) from DC Kits were a vastly different experience to Airfix products, offering the challenge of working with plastics other than styrene, as well as etched detailing parts. The need for scratch-built interiors, working out how to fit a power unit, and adding extra power collection from the trailing bogies, pushed my skills to the limit.

Originally introduced under the Rosebud/Kitmaster brands, these plastic loco kits proved to be their undoing as they simply couldnt cope with demand. Indeed, 4mm-scale modellers had been starved of high fidelity reproductions of Blue Pullman units, BR 9Fs, GWR and SR 4-4-0s or small tank locomotives, even if they did come unpowered. Eventually sold to Airfix in the late 1960s, most of the kits are still available today under the Dapol banner.

It took until my mid-twenties before I attempted anything as grandiose as a complete steam locomotive kit, although Id prepared myself for the challenge by dabbling in etched chassis building for some time beforehand. Beginning with the basic frame and bearing arrangements of locomotive tender chassis as replacement units for RTR models, the core skills were soon mastered, and confidence in the materials and processes developed, not least in the art of soldering.

This gradual approach also permitted the acquisition of tools and construction aids over a long period of time, spreading the cost and allowing each technique to be studied in turn. I doubt that many readers will be aiming to follow this twenty-five-year study path, but Ive endeavoured to present as much information as possible between this books covers, with each chapter concentrating on a specific process.