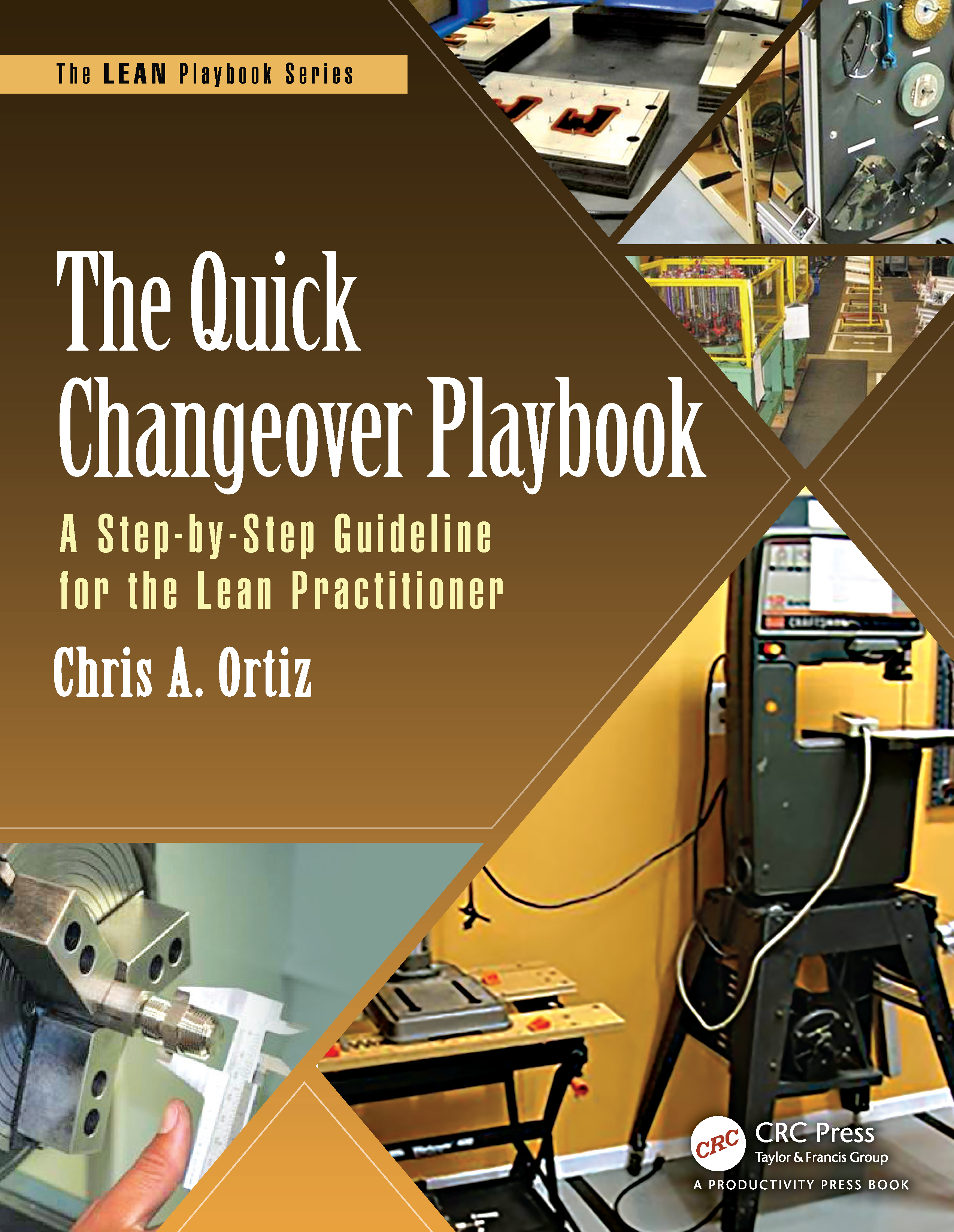

The Quick Changeover Playbook: A Step-by-Step Guideline for the Lean Practitioner

Chris A. Ortiz

CRC Press

Taylor & Francis Group

6000 Broken Sound Parkway NW, Suite 300

Boca Raton, FL 33487-2742

2015 by Taylor & Francis Group

CRC Press is an imprint of Taylor & Francis Group, an Informa business

No claim to original U.S. Government works

Version Date: 20160308

International Standard Book Number-13: 978-1-4987-8832-8 (EPUB)

This book contains information obtained from authentic and highly regarded sources. Reasonable efforts have been made to publish reliable data and information, but the author and publisher cannot assume responsibility for the validity of all materials or the consequences of their use. The authors and publishers have attempted to trace the copyright holders of all material reproduced in this publication and apologize to copyright holders if permission to publish in this form has not been obtained. If any copyright material has not been acknowledged please write and let us know so we may rectify in any future reprint.

Except as permitted under U.S. Copyright Law, no part of this book may be reprinted, reproduced, transmitted, or utilized in any form by any electronic, mechanical, or other means, now known or hereafter invented, including photocopying, microfilming, and recording, or in any information storage or retrieval system, without written permission from the publishers.

For permission to photocopy or use material electronically from this work, please access www.copyright.com or contact the Copyright Clearance Center, Inc. (CCC), 222 Rosewood Drive, Danvers, MA 01923, 978-750-8400. CCC is a not-for-profit organization that provides licenses and registration for a variety of users. For organizations that have been granted a photocopy license by the CCC, a separate system of payment has been arranged.

Trademark Notice: Product or corporate names may be trademarks or registered trademarks, and are used only for identification and explanation without intent to infringe.

Visit the Taylor & Francis Web site at http://www.taylorandfrancis.com

and the CRC Press Web site at www.crcpress.com

CRC Press is a premier publisher of scientific, technology and medical content, reaching around the globe to publish the pioneering achievements of science that provide researchers, professionals, and students with the resources they need to make further advances. CRC Press is a member of Taylor & Francis Group, an informa business.

For more authoritative books in your field and for in-depth information about CRC Press books, visit www.crcpress.com

- Join our email list to receive exclusive, unadvertised discounts and alerts when new books publish in your field

- Visit Featured Authors to learn about your favorite author with detailed bios, news about their work, and discussions of their research

- Read the latest book reviews from industry experts, influencers, and thought leaders about STM (Science, Technology and Medicine) reference and textbooks

The tables in this ebook have been modified to enhance the reader experience. On compatible devices, the enhancement should keep the header rows visible as you scroll through a table.

Please report any issues with this ebook or any desired enhancements to the .

www.crcpress.com

How to Use This Playbook

In most cases, a playbook is a spiral bound notebook that outlines a strategy for a sport or a game. Whether for a football game, a video game, or even a board game, playbooks are all around us and when written properly provide immediate and easily understood direction. Playbooks can also provide general information; then, it is up to the user of the playbook to tailor it to their individual needs.

Playbooks contain pictures, diagrams, quick references, definitions, and often step-by-step illustrations to explain certain parts. You can use playbooks to help you understand the entire game or you can pick and choose to focus on one element. The bottom line is that any playbook should be easy to read and to the point and contain little to no filler information.

The Quick Changeover Playbook is written for the Lean practitioner and facilitator. Like a football coach, a facilitator can use this playbook for quick reference and be able to convey what is needed easily. If for some reason the person leading the actual quick changeover implementation forgets a play the playbook can be referenced.

Either you can follow page by page and use the playbook to facilitate a Quick Changeover implementation or you can go directly to certain topics and use it to help you implement that particular play.

Introduction

This Quick Changeover Playbook is your guideline for implementation and is written for the pure Lean practitioner looking for a training tool and a guideline that can be used in the work area while improvements are being conducted. There is no other book, manual, or reference guide that provides color images and detailed step-by-step guidelines on how to develop and implement quick changeover concepts. The Quick Changeover Playbook is not a traditional book, as you can probably see. It is not intended to be read like another Lean business book. The images in this playbook are from real quick changeover implementations, and I use a combination of short paragraphs and bulleted descriptions to walk you through how to effectively reduce setup times on equipment.

Little or no time is wasted on high-level theory, although an introductory portion is dedicated to the 8 Wastes and Lean metrics. An understanding of wastes and metrics is needed to fully benefit from this playbook. This is not to imply that high-level theory or business strategies are not valuable; they are highly valuable. This playbook is for implementation, so it will not contain filler information.

Chapter 1 is a preliminary chapter and covers the basics of setup reduction and quick changeover and provides a foundation for a better understanding of the concepts in the remaining chapters. It goes over the four basic steps in a setup and explains the difference between a setup and a changeover. Often, these concepts are intermixed as having the same definition, but they are two very different steps in the whole process.

Data collection is covered in Chapter 2. Data collection is a critical piece in reducing setup times; this chapter goes into depth on how to properly collect time and motion studies specific to machines. Spaghetti diagram exercises also are discussed. Reviewing the data collected sets the tone for where improvements to overall setup and changeover can be seen. Sample forms, examples, and step-by-step pictures are included.

Using information collected from the spaghetti diagram and general waste analysis, Chapter 3 outlines the first pass of waste reduction through the implementation of the visual workplace and layout improvements. We revisit the concept of 5S (Sort, Set in Order, Scrub, Standardize, and Sustain) and visual organization because, in many cases, the one contributing factor to long setups is that the work environment provided for the operator is unorganized and cluttered. Images and illustrations from the 5S Playbook are used as well, but I include new pictures specifically in relation to setup reduction.

Chapter 4 is dedicated to two quick changeover concepts: intermediate tooling and one-turn methods. This chapter is unique and is one of the few, if not the only, reference books on the market to show examples of these concepts in real life. Intermediate tooling is a concept of converting internal work (machine off) into external work (machine on). It greatly reduces changeover times and allows for more output. The one-turn method is a concept of reducing or eliminating turning operations when removing paneling or tooling that has threaded fasteners. A sample one-turn method assessment form is provided as well. Once you have implemented the visual workplace, most of the improvements come in the form of machine modifications, engineering ideas, and maintenance changes. Physical changes and upgrades to equipment can have a profound impact on changeover; this chapter provides examples of these two concepts. However, working knowledge and technical expertise of the machines at your facility are needed to make customized improvements.