Table of Contents

List of Tables

- Chapter 1

- Chapter 2

- Chapter 3

- Chapter 4

- Chapter 5

- Chapter 6

- Chapter 7

- Chapter 8

- Chapter 9

- Chapter 10

- Chapter 11

- Chapter 12

- Chapter 13

- Chapter 14

- Chapter 15

- Chapter 16

- Chapter 17

- Chapter 18

List of Illustrations

- Chapter 1

- Chapter 3

- Chapter 4

- Chapter 5

- Chapter 6

- Chapter 7

- Chapter 8

- Chapter 9

- Chapter 10

- Chapter 11

- Chapter 12

- Chapter 13

- Chapter 14

- Chapter 15

- Chapter 17

- Chapter 18

- Chapter 19

Guide

Pages

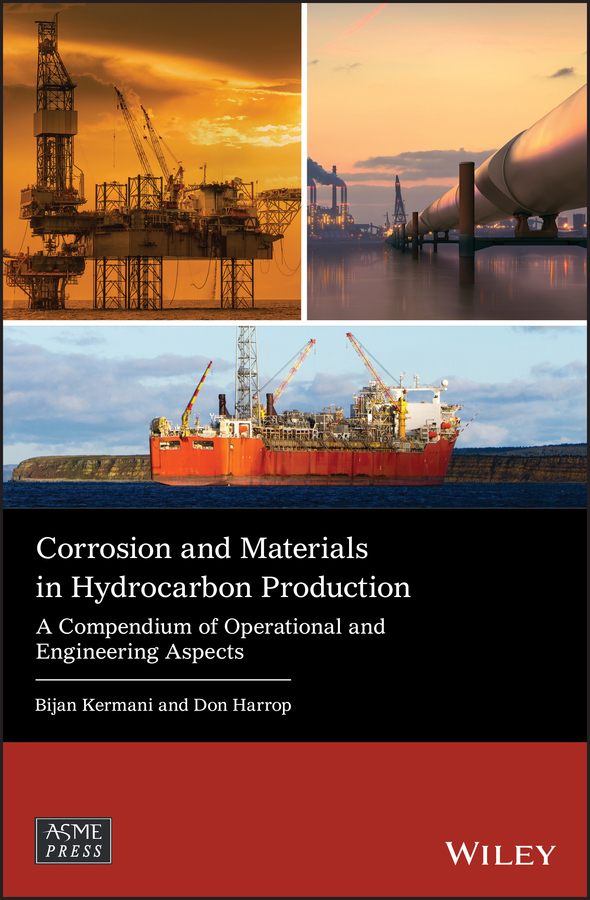

Corrosion and Materials in Hydrocarbon Production

A Compendium of Operational and Engineering Aspects

Bijan Kermani

NACE Fellow (F NACE), Fellow of Institute of Materials, Minerals and Mining (FIMMM), Fellow of Institute of Corrosion (FICorr) Chartered Engineer (CEng)

Don Harrop

Honorary Fellow of the UK Institute of Corrosion (FICorr)

Honorary Fellow of the European Federation of Corrosion (EFC)

This Work is a copublication between ASME Press and John Wiley & Sons Ltd.

2019 John Wiley & Sons Ltd

This Work is a copublication between John Wiley & Sons Ltd and ASME Press

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, except as permitted by law. Advice on how to obtain permission to reuse material from this title is available at http://www.wiley.com/go/permissions.

The right of Bijan Kermani and Don Harrop to be identified as the authors of this work has been asserted in accordance with law.

Registered Offices

John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, USA

John Wiley & Sons Ltd, The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, UK

Editorial Office

The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, UK

For details of our global editorial offices, customer services, and more information about Wiley products visit us at www.wiley.com.

Wiley also publishes its books in a variety of electronic formats and by printondemand. Some content that appears in standard print versions of this book may not be available in other formats.

Limit of Liability/Disclaimer of Warranty

While the publisher and authors have used their best efforts in preparing this work, they make no representations or warranties with respect to the accuracy or completeness of the contents of this work and specifically disclaim all warranties, including without limitation any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives, written sales materials or promotional statements for this work. The fact that an organization, website, or product is referred to in this work as a citation and/or potential source of further information does not mean that the publisher and authors endorse the information or services the organization, website, or product may provide or recommendations it may make. This work is sold with the understanding that the publisher is not engaged in rendering professional services. The advice and strategies contained herein may not be suitable for your situation. You should consult with a specialist where appropriate. Further, readers should be aware that websites listed in this work may have changed or disappeared between when this work was written and when it is read. Neither the publisher nor authors shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

Library of Congress CataloginginPublication data applied for

ISBN: 9781119515722

A catalogue record for this book is available from the British Library.

Cover Design: Wiley

Cover Images: ggw/Shutterstock, chain45154/Getty Images, spooh/Getty Images

To our families

Preface

Government policy in the pursuit of a carbonneutral world economy has been a commitment adopted by an increasing number of industrial nations. However, for the foreseeable future, fossil fuels in which hydrocarbons will play a significant role are likely to remain the primary source of energy.

There is a continuing drive to increase the life of existing oil and gas field developments through a number of avenues. These include, for example, tiebacks from nearby smaller reservoirs, otherwise uneconomic to develop alone, and by increasing the recovery rate from existing fields. The average commonly reported recovery rates after primary (natural flow under existing reservoir pressure) and secondary (e.g. water injection, hydraulic fracking) enhancement operations for oil are between 35% and 45%. This could potentially be increased in certain reservoirs by a further 515% through tertiary recovery methods (e.g. reducing reservoir oil viscosity by CO2 flooding, steam, or surfactant injection). Nevertheless, there remains a continuing search for new economic sources of hydrocarbons, taking exploration activities into harsher environments through deep high pressure/high temperature (HPHT) wells, into geographically remote and/or increasing environmentally sensitive areas and deep water. This enterprise has created increased challenges: (i) to the economics of project development and field operations; (ii) on the performance envelope of existing oilfield technology; and (iii) in meeting Health, Safety and Environment (HS&E) commitments which can impact the Licence to Operate (LTO). Ensuring the mechanical integrity of facilities is therefore paramount. The accurate prediction of materials performance and their optimised selection in tandem with proactive corrosion mitigation are primary considerations at design and throughout a field's operating life.

Hydrocarbonsproducing facilities and infrastructures are potentially subject to both external and internal corrosion threats; in the case of the former from hostile and geographically remote operating environments, and in the latter from the presence of wet produced fluids and acid gases. Both these threat types impact materials selection, engineering design, and through life integrity management (IM).

Corrosion in its various forms remains a major potential threat to successful hydrocarbons production and its optimum control and management are essential to the costeffective design of facilities and their safe operations. Its impact can be viewed in terms of effect on capital and operational expenditure (CAPEX and OPEX) and HS&E and associated process safety risks. It is, therefore, essential to have a sound corrosion design and management philosophy for production facilities to safely handle and transport wet hydrocarbons enabling integrity assurance and troublefree operations. Such a philosophy can be used in the technical/commercial assessment of new field development and in prospect evaluation, to prolong the life of ageing assets and, for handling sour fluids by facilities not normally designed for sour service. The book sets out to provide such a philosophy in a pragmatic manner.

The book is intended to be suitable for both practising materials and corrosion engineers working in hydrocarbons production as well as those entering the area who may not be fully familiar with the subject. It is not a textbook; rather it is a practical manual/ready reference source to steer design and operations engineers to currently established best practice drawn on the many years' global experience of the book's authors and contributors. It embodies over 500years of cumulative field and engineering experience.

Next page