1.1 Range and application of commercial bulk magnetic materials

The growing reliance on renewable energy, increasing concern over energy efficiency and the drive towards hybrid and all-electric transport stimulate the need for high performance magnetic materials and their most effective use in electrical equipment. Magnetic materials are broadly classed as being either hard or soft based on how difficult it is to alter their internal magnetisation.

An efficient hard magnetic material has to be placed in a large magnetic field to become fully magnetised, but when removed from the field it retains that magnetism. In the magnetised state it is commonly referred to as a permanent magnet. On the other hand, a soft magnetic material is much easier to magnetise fully but it loses most, or even all, of its net magnetisation when the field is removed. Soft magnetic materials are sometimes referred to as temporary magnets. The first commercial permanent magnet alloys happened to be mechanically hard and the first metallic magnetic materials suitable for use in rapidly changing magnetic fields happened to be mechanically soft; this nomenclature is still used today irrespective of the mechanical state of the magnetic material.

The magnetic flux density is of major importance in any engineering application. Whether it has a constant magnitude (d.c. or static) or changes with time (a.c. or dynamic), its fundamental role may be one or more of the following three basic functions:

- to produce a voltage proportional to its rate of change with time,

- to generate a force proportional to its magnitude on a current-carrying conductor or

- to create an attractive force between magnetised surfaces proportional to the square of its magnitude.

The purpose of a hard or soft magnetic material in electromagnetic devices such as electricity generators, motors, actuators or transformers is to produce and help control the magnitude and direction of the magnetic flux needed in a power transfer or conversion process. In a transformer the flux effectively acts as a medium to convert electrical energy from one voltage level to another. In a motor the magnetic flux in the air gap between the rotor and stator determines the transfer of mechanical energy to or from electrical energy, whereas in a generator the airgap flux also has a strong effect on the wave shape of the resulting output voltage.

Hard magnetic materials are critical components in many household, transport and industrial applications often incorporating low cost, compact, high power, energy efficient actuators, motors and generators. Although hard magnetic materials are not a theme of this book, it is useful briefly to compare some properties with those of soft magnetic materials. After all, in many applications they are used alongside each other.

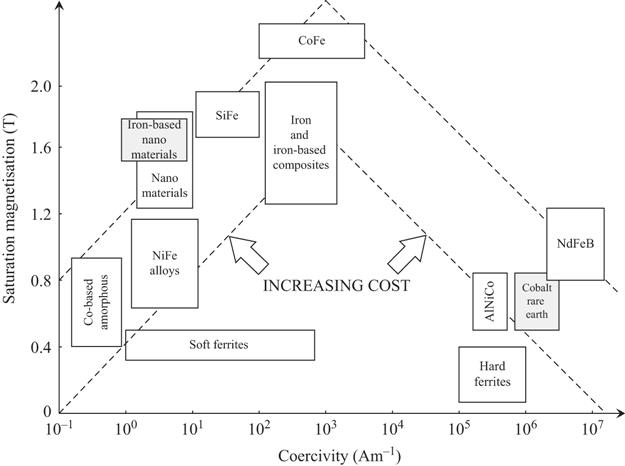

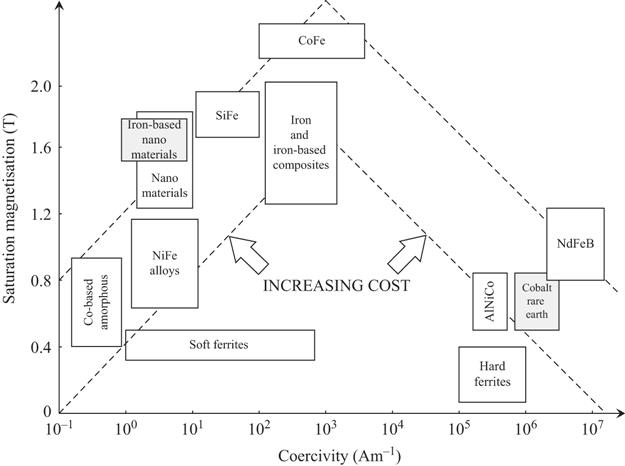

shows where the most common families of magnetic materials roughly lie on a saturation magnetisation versus coercivity graph. These parameters are two of the most important characteristics of any magnetic material. The commercial nickeliron (NiFe) alloys, amorphous magnetic ribbon and soft magnetic nano-crystalline materials have the lowest coercivity indicating that they are the easiest of all soft magnetic materials to magnetise or demagnetise. Neodymiumironboron (NdFeB) compounds, members of the rare earth magnet family, have the highest coercivity so they can retain a state of permanent magnetisation better than any other commercial hard magnetic material. It is interesting to note that the magnitude of the coercivity varies by a factor of over 100 million between the softest and hardest material.

Figure 1.1 Range of coercivity, saturation magnetisation and cost trends of families of commercial soft and hard magnetic materials

The physical volume or weight of magnetic components and also the quantity of magnetic energy that electromagnetic systems can store is dependent on the saturation magnetisation of the incorporated soft or hard magnetic materials. indicates that the highest saturation magnetisation in common commercial magnetic materials is achieved in cobaltiron (CoFe) alloys and the lowest in the soft and hard ferrites. Pure iron itself has the highest saturation magnetisation of any element but its resistivity is very low so eddy current losses, which will be seen later to be crucially important in soft magnetic materials, are very high under alternating (a.c.) magnetisation. Therefore its use is mainly restricted to d.c. applications.

It is perhaps not surprising that both the best soft materials (very low coercivity together with high saturation magnetisation) and the best hard materials (very high coercivity together with high saturation magnetisation) are the most expensive. This is due to high costs of either the raw material, the production process or both. The families of soft magnetic materials included in are discussed in detail in Chapters 1517.

In addition to saturation magnetisation and coercivity, permeability and energy losses are important properties of soft magnetic materials in many applications. The largest single application of soft magnetic materials is found in power conversion equipment where energy is transmitted via magnetic flux such as in a transformer core. High magnetic permeability of the magnetic material helps tightly link the flux between primary and secondary electrical windings and, at the same time, concentrates the flux to enable high energy transfer and to minimise core size. Soft magnetic materials used in motor and generator cores have a similar function, but an effective combination of their specific magnetic properties and core geometry helps control and optimise the magnitude and spatial profile of the magnetic flux in the air gap between the stator and rotor needed to obtain effective power transfer.

Another important application of soft magnetic materials is as magnetic shielding for protecting sensitive electrical equipment from electromagnetic radiation or, conversely, by providing a barrier to stop large magnetic fields, such as those generated in medical imaging systems, from being a potential human hazard. The basic shielding is simply a box of a suitable magnetic material designed to capture the unwanted airborne magnetic flux and divert it away from the area to be protected.

1.2 Industrially important characteristics of soft magnetic materials

In most applications the main purpose of soft magnetic materials is to control either or both the direction and magnitude of magnetic flux. However, there are many factors which determine how suitable a material might be for a specific application. The first consideration is what specific magnetic flux conditions are required in the material, e.g. its magnitude, d.c. or a.c., and, if a.c., the magnetising frequency and magnetic flux waveform. Next, the working environment must be considered to ensure that the magnetic performance is not adversely affected by factors such as high or low ambient temperature or subjection to mechanical stress.

The a.c. magnetisation will generate energy losses and acoustic noise might be generated due to magnetostriction. The determination of the most appropriate material is usually a balance between material cost, performance and application; however, the ultimate suitability of a material might be determined by the availability of a material in a physical form compatible with component design and manufacturing steps.

If the magnetising frequency is fixed in a particular application the range of possible suitable materials is reduced. Eddy currents, sometimes still referred to as Foucault currents in recognition of the discoverer, Lon Foucault, are created within a magnetic material when its internal magnetisation changes and if the change is rapid, e.g. at high magnetising frequency, the effective magnetic permeability falls so the material becomes difficult to magnetise, also magnetic losses increase. It is worth clarifying what is meant by