Published in 2018 by The Rosen Publishing Group, Inc. 29 East 21st Street, New York, NY 10010

Copyright 2018 by The Rosen Publishing Group, Inc.

First Edition

All rights reserved. No part of this book may be reproduced in any form without permission in writing from the publisher, except by a reviewer.

Library of Congress Cataloging-in-Publication Data

Names: La Bella, Laura, author.

Title: The future of robotics / Laura La Bella.

Description: New York : Rosen Publishing, 2018 | Series: Hands-on robotics | Includes bibliographical references and index. | Audience: Grades 5-8. Identifiers: LCCN 2017024559| ISBN 9781499438901 (library bound) | ISBN 9781499438888 (pbk.) | ISBN 9781499438895 (6 pack)

Subjects: LCSH: RoboticsJuvenile literature. | RobotsJuvenile literature. Classification: LCC TJ211.2 .L3 2018 | DDC 629.8/92dc23 LC record available at https://lccn.loc.gov/2017024559

Manufactured in the United States of America

E verywhere you look, you can find robots engaged in activities both simple and complex. Robotics combines computer science, engineering, and electronics to create devices that can perform a variety of tasks, many of which are too complicated, too precise, or nearly impossible for humans to perform. What defines a robot from merely a machine that can accomplish a task is advanced computing.

Robots are programmed to make limited decisions based on certain scenarios. Thats why a robotic arm on a manufacturing floor can accurately weld vehicle parts together or install microchips on a circuit board, and recognize if something is not quite right in the process. This simple version of artificial intelligence (AI) enables the robot to spot mistakes in manufacturing as they occur or are about to.

Right now, robotics is being utilized in manufacturing to help assemble automobiles, furniture, and prepare and package a seemingly endless stream of other products. It is used to automate apparatuses to explore the depths of our oceans and the farthest reaches of space. In hospitals, on farms, and in our national security and defense, robotics is poised to take over many tasks in the very near future.

Robotics may also deliver highly advanced technologies on a very tiny scale. Nanobots, or tiny robots, could one day swim through our bloodstreams to deliver medications to specifically targeted sites within our bodies to treat a wide range of illnesses and diseases. Robofish are being tested in the waters off Spain to detect and locate contaminated water and report it back to land. And, in a fascinating partnership that may reduce the time it takes to rescue victims of natural disasters, snake-bots are teaming up with rescue dogs. The dogs will sniff out and locate a disaster victim and deploy a snakebot, which can relay video and audio of the situation back to medical personnel and rescue workers.

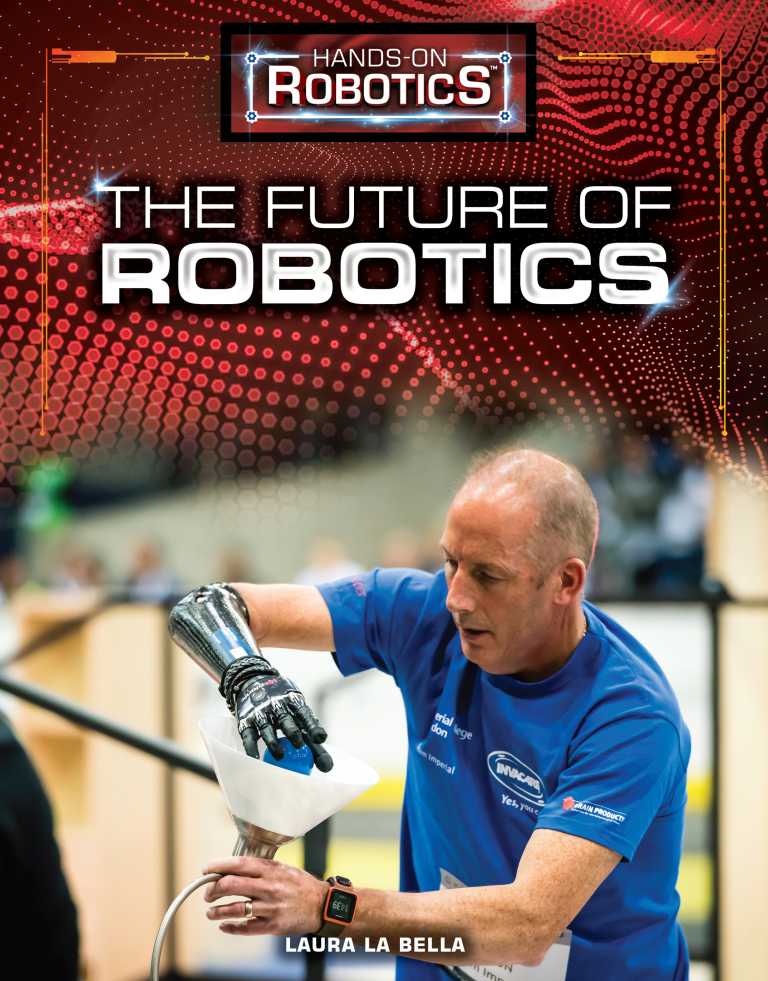

A Pepper humanoid robot, designed by SoftBank Group as a companion robot to recognize and respond to human emotion, stands inside the Mizuho Financial Group headquarters in Tokyo, Japan, in April 2017.

The future of robotics is exciting and promising. As new technology emerges, inspired by the innovations of scientists, engineers, and programmers, the ways society at large uses robotics will surely multiply. It is hoped that robotic technologies will improve and streamline processes in manufacturing, health care, law enforcement, education, entertainment, and more. Artificial intelligence, coupled with robotics, will create machines that are highly interactive, that anticipate our needs and act to meet them, and even be able to solve problems without our prompting them to do so.

The possibilities for the future of robotics remain great. The only limits seem to be the human imagination and how much work and financial resources we are willing to throw at them. In some ways, the future is not far off. Its now.

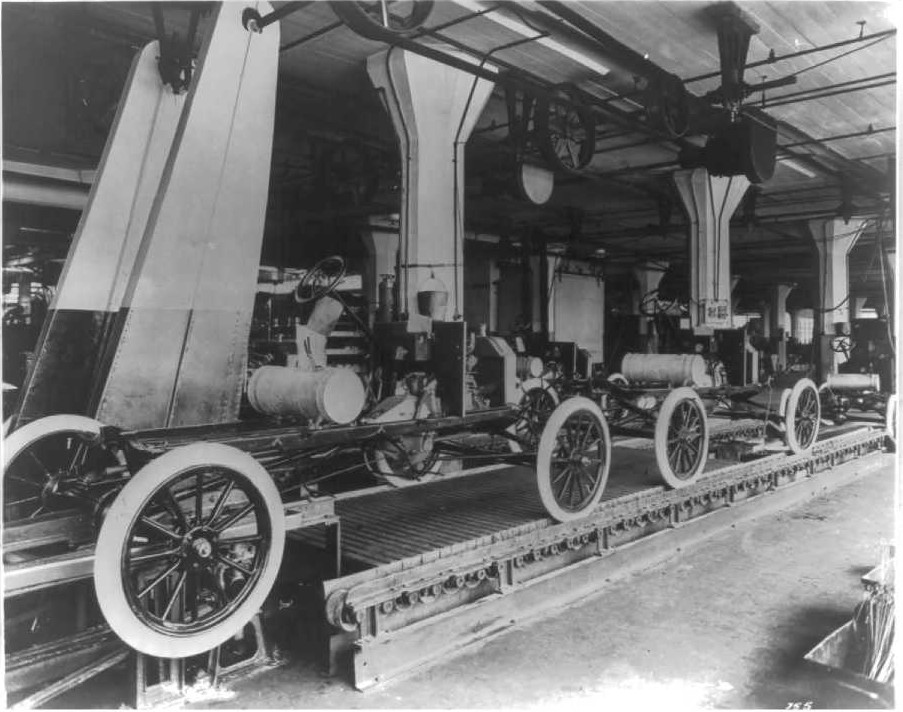

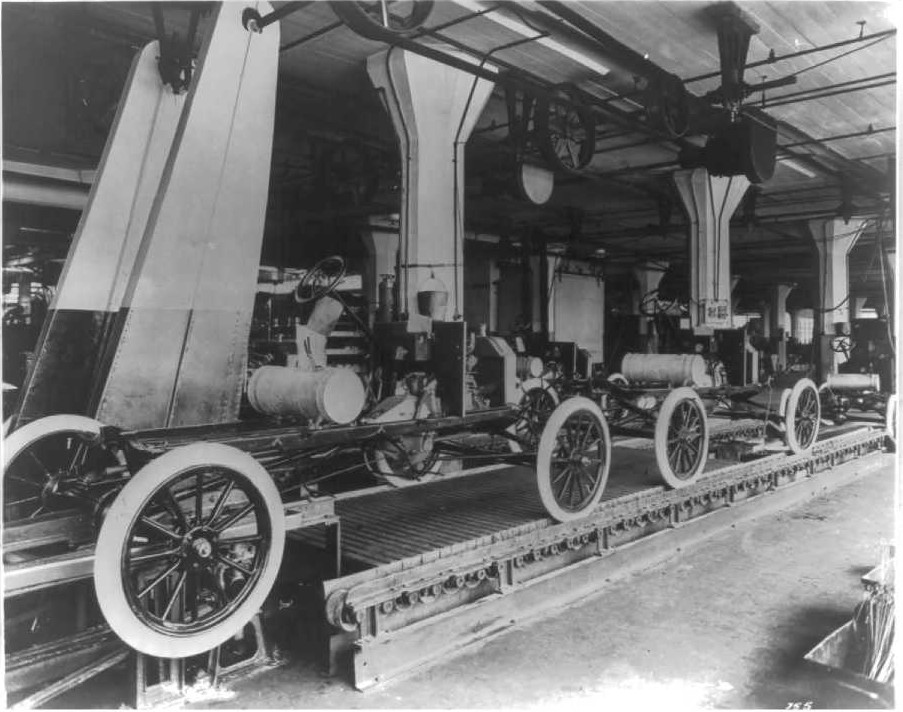

H enry Ford, the pioneering automobile manufacturer, first automated the assembly line in car production in 1913 with a conveyor belt. The belt had been used since the late eighteenth century in mines and rail yards to move heavy material and equipment, but now it was put to use to expand automobile production. Ford had machines built that could stamp out car parts automatically and with more precision and speed than his human workers. All these measures vastly improved the rate of production. Fords innovations reduced the time it took to manufacture a car from twelve hours to just under three. It was the first automated assembly line and the first time basic robotics were used in manufacturing. Manufacturing, and all the various industries that would soon employ it in mass production, would never be the same.

WHAT ARE ROBOTS AND HOW DO THEY WORK?

When many people think of robots, they might imagine robots that look like humans and that are capable of communication and accomplishing the types of tasks that people normally perform. For most of the modern era, however, this kind of robot has actually been quite uncommon and has been restricted mostly to science fiction, including novels, stories, films, and television.

While humanoid robots exist, it is far more common to encounter a robot that embodies a part of a human shape, such as a robotic arm, or a machine that incorporates robotic technology but looks more machine than human. Most leading roboticiststhe specialists who develop, design, and build robotshave defined a robot as having a programmable brain, or computer, with a physical body that can move. Using this definition, robots are different from machines, such as cars or lawnmowers, because they have advanced computing that helps control their movements, rather than direct human control. Some can even make simple decisions, and these decision-making abilities are likely to increase vastly in the coming years and decades. Of course, even cars and planes themselves have begun to incorporate simple systems of artificial intelligence and robotics, and these two will grow more advanced.

This image from around 1913 shows the automobile assembly line at the Ford Motors plant at Highland Park, Michigan. Fords innovations in mass production included some of the successful and influential examples of automation.

The inner workings of a banks automated or automatic teller machine (ATM) are shown here.

Robots are mechanical devices that are capable of performing tasks on command or according to the directions they are programmed to follow. While there are many automated services that seem to resemble robots in a variety of waysfor instance, self-checkout machines at the supermarket, automated telephone systems, etc.these systems are actually limited in their ability to interact with you. They cannot make decisions, nor can they adapt to their surroundings.