Murzin - Chemical Reaction Technology

Here you can read online Murzin - Chemical Reaction Technology full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2015, publisher: De Gruyter, genre: Children. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

Chemical Reaction Technology: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Chemical Reaction Technology" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Chemical Reaction Technology — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Chemical Reaction Technology" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

Dmitry Yu. Murzin studied chemistry and chemical engineering at the Mendeleev University of Chemical Technology in Moscow, Russia (19801986), and graduated with honors. He obtained his PhD (advisor Prof. M. I. Temkin) and DrSc degrees at Karpov Institute of Physical Chemistry, Moscow, in 1989 and 1999, respectively. He worked at Universite Louis Pasteur, Strasbourg, France, and bo Akademi University, Turku, Finland, as a post-doc (19921994). In 19952000, he was associated with BASF, being involved in research, technical marketing, and management. Since 2000, Prof. Murzin holds the Chair of Chemical Technology at bo Akademi University. He serves on the editorial boards of several journals in catalysis and chemical engineering field. He is an elected member of the Societas Scientiarum Fennica and Svenska Tekniska Vetenskapsakademien i Finland science academies. Prof. Murzin is the co-author (with Prof. T. Salmi) of a monograph ( Catalytic Kinetics , Elsevier, 2005) and an author of a textbook ( Engineering Catalysis , De Gruyter, 2013). He holds several patents and is an author or co-author of ca. 600 journal articles and book chapters.

It is the authors opinion that the content of textbooks for graduate students should be accurate and precise rather than original. Therefore, during the writing of this textbook, the author had consulted different sources including various encyclopedia, textbooks, review papers, original articles, companies websites, information portals, etc., with the aim of giving as precise and correct information as possible. However, some relevant information on novel technologies might be missing or obsolete technologies are described; therefore, any comments, corrections, and updates would be highly appreciated.

In very many cases, while compiling the text, difficult decisions had to be taken regarding the level of details that should be included for particular processes. There are many textbooks and reference books that provide much more extensive descriptions. The author has, for example, books of several hundreds of pages devoted just to ammonia or methanol synthesis, hydroformylation, oxychlorination, etc. A helicopter view showing how general principles of chemical reaction technology are utilized for particular cases was thus adapted in the textbook. More specialized literature should be consulted in a quest for more precise descriptions of various chemical processes.

The author is grateful to the editorial team at De Gruyter, namely Karin Sora, Julia Lauterbach and Sabina Dabrowski, for efficient collaboration. Technical help of Elena Murzina with drawing figures is highly appreciated.

Finally, the author hopes that the knowledge on chemical reaction technology can be transferred from one process to another and that the book could be interesting not only for students, but also for professionals working in chemical process industries.

Chemical technology can be defined as a science of converting natural resources or other raw materials into the desired products at the industrial scale using chemical transformations in a technically and economically feasible and socially acceptable way. Besides being based on sound economical considerations, chemical production should nowadays take into account ecological aspects, safety requirements, and labor conditions.

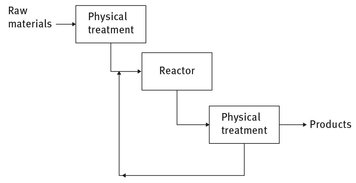

Chemical technology investigates chemical processes (whose structures had been given in ), which comprise feed purification, reactions per se , separation, and product purification.

Chemical technology is not limited only to chemical transformations per se , as there are other various physical, physico-chemical, and mechanical processes in the production of chemicals.

Criteria of a process quality are technological parameters (productivity, conversion, yield, product purity) as well as economical (costs, profitability, etc.) and ecological ones.

Success in implementation of a novel technology requires its robustness, reliability, safety, environmental compliance as well as significant gains over existing processes.

Methods of chemical technology are used also in non-chemical industries, such as transport, metallurgy, building construction, electronic industry.

Chemical technology as a discipline is based on the following:

- Physical chemistry and chemical reaction engineering, covering stoichiometry, catalysis

: General structure of chemical processes.

- Unit operations, which include besides reactors also various separation processes, such as extraction

- General process considerations, viewing chemical production as a chemical technological system and applying principles of conceptual process design, process intensification, and green chemical engineering

hydrogenation of benzene. For a physical chemist, the reaction will look like C6H6 + 3H2 = C6H12 H, leading to a conclusion that the reaction is reversible and exothermal and that the parameters that could be used to alter equilibrium are temperature and concentrations (pressures) of reagents. When developing a process technology of benzene hydrogenation, other parameters aside from the issues mentioned above should be considered such as availability of the feedstock and energy, reactor type, other pieces of equipment needed, the phase in which the reaction should take place (gas or liquid), the optimal conditions from the viewpoint of economics, and minimization of the negative impact on the environment.

This simple example illustrates that chemical technology is different from organic (inorganic) and physical or other branches of chemistry.

Chemical processes in oil refining and production of basic chemicals are mainly continuous, while in production of specialty and fine chemicals, they could be continuous and periodical. The latter mode of operation can be also used in the secondary processes (i.e., separation, catalyst regeneration) even for large-scale production in chemical process industries (sometimes abbreviated as CPIs).

Continuous processes typically require constant technological parameters (pressure, flows, temperature). Such processes are mainly aimed at production of a single product. In periodical (batch) processes, several products could be made under somewhat similar conditions.

Semi-periodical processes can be also applied in continuously operating units, with, however, a change of a product after a certain period of time.

Continuous mode of operation allows constant quality of products, very efficient utilization of the equipment, high degree of process automation and control, and finally, much more efficient and safe processes.

In order to organize a continuous process, the following conditions should be fulfilled:

- separation of inlet and outlet in a reactor space

- continuous and substantially stationary flows of reactants and products (even if there are several successful examples of non-stationary operation)

- the products should be the same during the operation

Font size:

Interval:

Bookmark:

Similar books «Chemical Reaction Technology»

Look at similar books to Chemical Reaction Technology. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Chemical Reaction Technology and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.