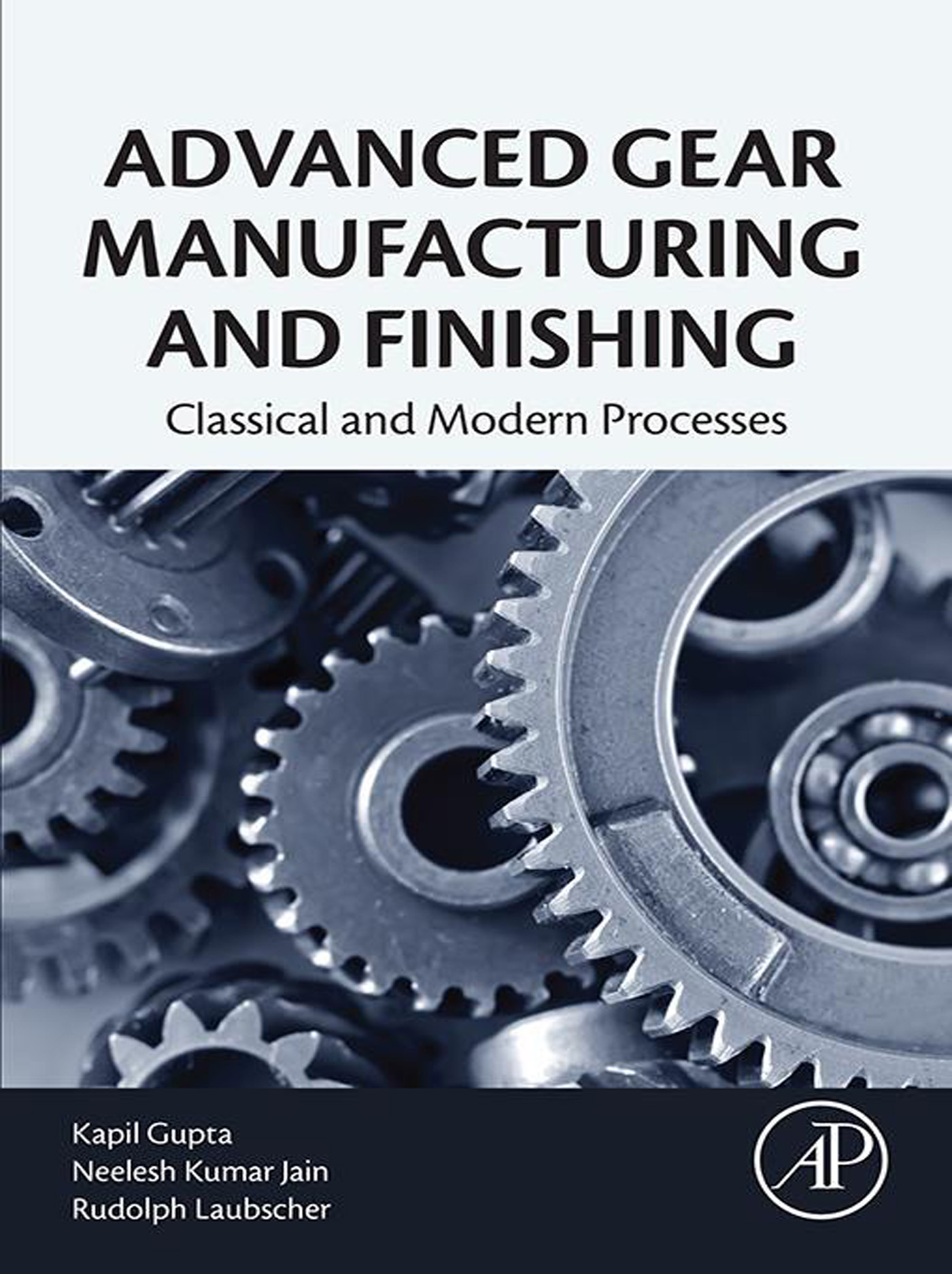

Gupta Kapil - Advanced Gear Manufacturing and Finishing: Classical and Modern Processes

Here you can read online Gupta Kapil - Advanced Gear Manufacturing and Finishing: Classical and Modern Processes full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2017, publisher: Academic Press, genre: Children. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Advanced Gear Manufacturing and Finishing: Classical and Modern Processes

- Author:

- Publisher:Academic Press

- Genre:

- Year:2017

- Rating:4 / 5

- Favourites:Add to favourites

- Your mark:

- 80

- 1

- 2

- 3

- 4

- 5

Advanced Gear Manufacturing and Finishing: Classical and Modern Processes: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Advanced Gear Manufacturing and Finishing: Classical and Modern Processes" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Gupta Kapil: author's other books

Who wrote Advanced Gear Manufacturing and Finishing: Classical and Modern Processes? Find out the surname, the name of the author of the book and a list of all author's works by series.

Advanced Gear Manufacturing and Finishing: Classical and Modern Processes — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Advanced Gear Manufacturing and Finishing: Classical and Modern Processes" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

- Tables in Chapter 1

- Tables in Chapter 3

- Tables in Chapter 5

- Tables in Chapter 6

- Figures in Chapter 1

- Figures in Chapter 2

- Figures in Chapter 3

- Figures in Chapter 4

- Figures in Chapter 5

- Figures in Chapter 6

- Figures in Chapter 7

Kapil Gupta

Sr. Lecturer, Department of Mechanical and Industrial Engineering Technology, University of Johannesburg, Johannesburg, RSA

Neelesh Kumar Jain

Professor, Discipline of Mechanical Engineering, Indian Institute of Technology Indore, Indore, India

Rudolph Laubscher

Associate Professor, Department of Mechanical Engineering Science, University of Johannesburg, Johannesburg, RSA

Academic Press is an imprint of Elsevier

125 London Wall, London EC2Y 5AS, United Kingdom

525 B Street, Suite 1800, San Diego, CA 92101-4495, United States

50 Hampshire Street, 5th Floor, Cambridge, MA 02139, United States

The Boulevard, Langford Lane, Kidlington, Oxford OX5 1GB, United Kingdom

Copyright 2017 Elsevier Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publishers permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library

Library of Congress Cataloging-in-Publication Data

A catalog record for this book is available from the Library of Congress

ISBN: 978-0-12-804460-5

For Information on all Academic Press publications visit our website at https://www.elsevier.com/books-and-journals

Publisher: Matthew Deans

Acquisition Editor: Brian Guerin

Editorial Project Manager: Edward Payne

Production Project Manager: Anusha Sambamoorthy

Cover Designer: Victoria Pearson

Typeset by MPS Limited, Chennai, India

Kapil Gupta, Sr. Lecturer, Department of Mechanical and Industrial Engineering Technology, University of Johannesburg, Johannesburg, RSA

Neelesh Kumar Jain, Professor, Discipline of Mechanical Engineering, Indian Institute of Technology Indore, Indore, India

Rudolph Laubscher, Associate Professor, Department of Mechanical Engineering Science, University of Johannesburg, Johannesburg, RSA

Gears and the associated gear manufacturing industry maintain a unique but significant position in the manufacturing sector at large. Almost every manufacturing industry utilizes gears and/or gear assemblies in one form or the other as part of their manufacturing process. The gear industry is not immune to technological advancement and requires new processes and techniques to fulfill the requirements of new and unique specialized transmissions that are being developed all the time. This development of new and novel techniques along with the advancements in the conventional processes needs to occur within the framework of quality, productivity, and ecological impact.

The aim of this book is to provide a concise collection of research and development aspects, salient features, applications, process principles and mechanism of advanced gear manufacturing processes.

It consists of seven chapters that include an introduction to gear engineering, conventional and advanced gear manufacturing and finishing processes, surface modification of gears, and eventually concludes with a chapter on gear metrology. , Measurement of Gear Accuracy, where the gear metrology is presented and discussed.

The main audience targeted for this book is researchers, engineers, technical experts, and specialists working in the area of gear manufacturing and finishing.

The authors acknowledge Academic Press Inc. for this opportunity and for their professional support. Finally, the authors would like to thank all those who assisted during the development of this book.

Gears are basic mechanical components used to transmit motion and/or power and are responsible for the smooth functioning of a significant number of machines, instruments, and equipments employed in most major industrial, scientific, and domestic applications. The purpose of this chapter is to present a basic introduction to gears, their use, and manufacture. The chapter commences with an introduction to gears along with a brief history. A classification scheme is then presented based on the gear-shaft axis orientation and corresponding gear types with their unique features and applications. The applicable gear terminology and nomenclature along with the most important gear materials, their properties, and application areas are presented next. The chapter is concluded with a brief introduction into gear manufacture comprising both conventional and advanced types along with the relevant finishing processes.

Bevel gear; involute; gear hobbing; noncircular gear; spline; spur gear; worm wheel

A gear is basically a toothed wheel that works in tandem with another gear (or gears) to transmit power and/or motion to change speed and/or direction of motion. Dudley defined a gear as a geometric shape that has teeth uniformly spaced around the circumference and is made to mesh its teeth with another gear . Slipping is a major problem during transmission of motion and power between two shafts by rope or belt drive and consequently may affect the precision and efficiency of the system adversely. This slipping phenomenon is largely avoided by means of gear drives. The compact layout, flexibility, high efficiency, and reliability are the most important features that make gears and gear drives the first choice in many applications. Gear sizes range from nanometers (nanogears) to meters (macrogears) with corresponding application areas from nanoelectromechanical systems (NEMS) to large mills and wind turbines. A wide range of materials ranging from plastics and ceramics to ultrahigh strength steels are used in gear manufacture.

Font size:

Interval:

Bookmark:

Similar books «Advanced Gear Manufacturing and Finishing: Classical and Modern Processes»

Look at similar books to Advanced Gear Manufacturing and Finishing: Classical and Modern Processes. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Advanced Gear Manufacturing and Finishing: Classical and Modern Processes and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.