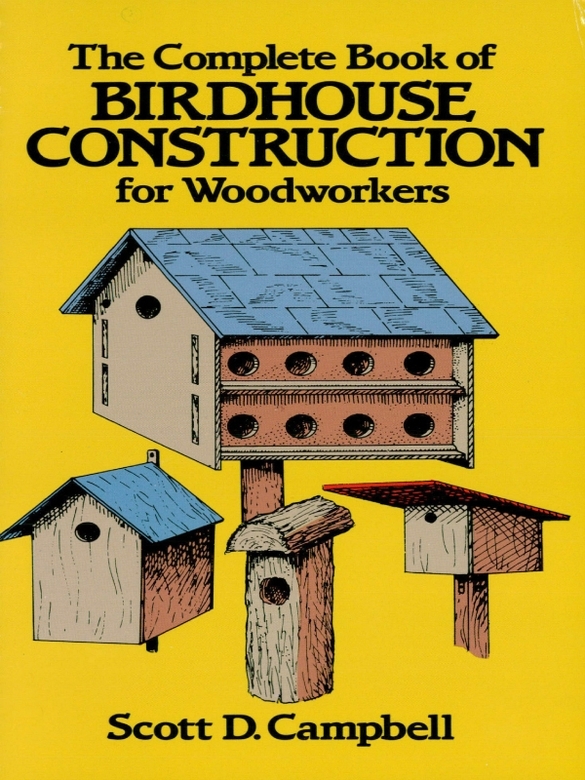

I.

Construction Materials

Wood is the best material for birdhouse construction, for a number of reasons. First, it is easily worked. You can cut, drill, and shape wood in a variety of ways. Second, it is a good insulator against temperature changes and noise. Third, it is widely available in a number of price ranges and in some cases may cost nothing (more on this later). Finally, properly constructed wood birdhouses are durable and can take a variety of different finishes in order to blend with their surroundings.

Wood is available for purchase at lumber and building-supply dealers, conveniently listed in the yellow pages of your phone book under Lumber. You may purchase stock or standard sizes of plywood or lumber, or if the company offers millwork you can have wood cut to your specifications for an additional price. Generally, those companies which advertise to the home handyman or do-it-yourselfer will give better service, but few offer millwork.

What type of wood should you buy? That depends of course on what woods are in stock and also on what characteristics and price range you desire. A durable wood such as cypress, cedar, or redwood will weather very well but is expensive, and cypress is especially hard to nail. A properly treated pine or fir birdhouse will last for years and is easy to construct. Yellow pine may have some pitch or resin pockets in some pieces, which will have to be cleaned and sealed before finishing. White pine is good and the grain is much less noticeable than in yellow pine. Plywood is both strong and convenient for laying out and cutting designs from, but be sure it is graded as exterior plywood, which means that waterproof glues were used to construct it. All cut edges of plywood should be sealed against moisture absorption.

What size lumber should be bought? Lumber should be bought in stock sizes to avoid additional millwork costs if possible. Wood thicknesses can be , , , or , as you prefer, though and lumber are more readily available from craft suppliers. Unfortunately, lumber is sold according to its thickness and width before seasoning and surfacing. Thus a board sold as 1 x 2 is actually about thick by 1 wide (see ). From the table you can see that to obtain boards at least thick and 5 wide, you must glue or nail one-by-threes together or buy one-by-sixes and trim if needed. Be sure to inquire about the actual size of the lumber you are buying if it will affect your plans. Stock lumber lengths are in feet: eight, ten, twelve, and greater lengths. Plywood dimensions are exactly as stated. Plywood is available in 4 x 8 panels and some stores offer it in smaller stock sizes, such as 2 x 4 or 2 x 2.

Lumber Sizes2

| Original Size (in inches) | Finished Size (in inches) |

|---|

| 1 2 | 1 |

| 1 3 | 2 |

| 1 4 | 3 |

| 1 5 | 4 |

| 1 6 | 5 |

| 1 8 | 7 |

| 1 10 | 9 |

| 1 12 | 11 |

| 2 4 | 1 3 |

| 4 4 | 3 3 |

| 2 Lowes 1974 Buyers Guide (North Wilkesboro, N.C.: Lowes Companies, Inc., 1974), p. 11. |

Lumber and plywood are also graded according to appearance (the smoothness of the surface and the number of knots or waste). Plywood has a letter designation for the quality of its surfaces. For instance, A/C plywood has a superior, smooth surface, designated A, and a somewhat rougher side, noted as a C side. The A side will naturally accept a finish better with less effort, and so should face out when the birdhouse is made. Your lumber dealer can help you select the grade of plywood or lumber you need. It is largely a matter of your own preference and the types in stock at the time of your purchase.

What about free wood? Some of the most natural and beautiful birdhouses are made from wood that costs little or nothing at all. Five-inch or larger-diameter logs can be bored or chiseled out to make handsome, sturdy houses. These logs can be found where storms down trees, where trees are cleared for construction, and as driftwood at lake shores. Old packing crates and broken pallets (wooden shipping platforms) are sometimes available at local warehouses. Sturdy, though cheaper and sometimes rough-cut, lumber is used to protect many items that are too expensive or too heavy to be safely shipped in cartons alone. After you have checked the price of lumber at lumber companies you may feel it worthwhile to check with the shipping and receiving departments of larger businesses in your area. A warehouse in this authors area has regularly transported truckloads of damaged pallets to the city dump because the labor and material costs to repair them are not practical.

There is one final type of wood available: rough-sawn wood. Normally wood is cut and then planed to give it a level, smooth surface. Rough-sawn wood, as the name implies, is left in a rough condition for a rustic appearance. Commercial birdhouse builders often groove or otherwise antique the wood for that natural or weathered look. Rough wood surfaces are undoubtedly easier also for birds when climbing out of deep birdhouses. This method is most effective with woods like cedar, which age well without painting. Ask your lumberman about obtaining rough-sawn lumber.

Of course wood is not the only material that may be used. Novelty houses have been made from coconut shells, gourds, flowerpots, and various other items, including cement-coated wire mesh. The emphasis in this book, however, will be on the wooden birdhouse.

Tools of the Trade

A brace and bit or small electric drill is required for making entrance, ventilation, and drainage holes. Use drill bits for ventilation and bits for drainage holes if they are required by your design. The most common bit sizes for entrance holes are 1, 1, 1, and 1. An adjustable hole saw for use with an electric drill will also cut many larger-size holes.

The lumber may be cut to size with a handsaw. A keyhole saw or a coping saw is used to cut the big-diameter entrance holes for larger birds. The short and sturdy back saw is helpful in making miter and bevel cuts. If power tools are available, the saber saw or the jig saw, which are adjustable for bevel cuts, will perform all the sawing operations needed, except cutting logs.