Appendix

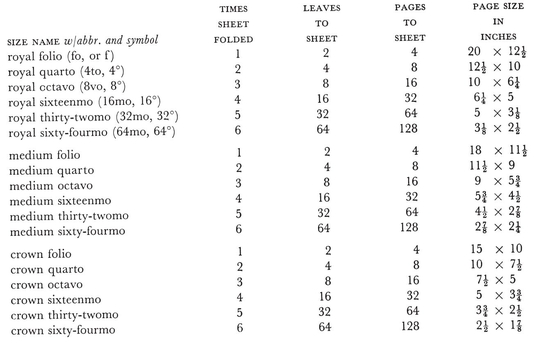

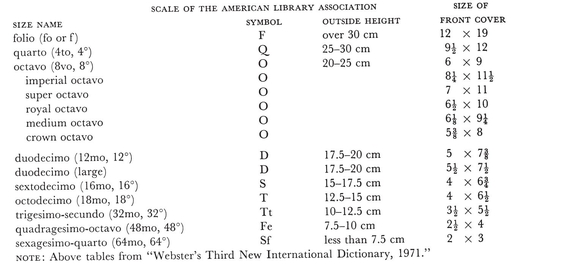

Book Sizes

The system of denoting book sizes is very old. It was based on the size of sheet prevailing at the time, and the size into which it was folded to make each section or signature. There is always an even number of pages to a section, the sheet being folded so as to produce 4, 8, 12, 16, 24, 32, 48, 64 pages, and so on. (Only one half as many leaves as pages, since a leaf, printed on both sides, consists of 2 pages.) The tables below give information for certain sizes of modern sheets, though actual page sizes may be a little smaller than the figures given, since the book is trimmed an undetermined amount at head, tail and fore edge. British sheet sizes also differ somewhat from the American, and the page sizes therefore will also differ a little.

Sources of Supply in the United States

Suppliers to the bookbinding trade:

Gane Bros. & Lane, Inc.

1400 Greenleaf Ave.

Elk Grove Village, Ill. 60607

(Chicago area)

with branches at :

2655 Metro Blvd.

St. Louis, Mo. 63043

1228 Forest Pkwy.

Paulsboro, N.J. 08066

(New York City area)

2839 Blystone Lane

Dallas, Texas 75220

150 Mendel Drive, S.W.

Atlanta, Georgia 30336

4697 East 48th Street

Vernon, California 90058

(Los Angeles area)

Bookbinding tools, supplies ,

general hobby supplies:

The Craftool Co., Inc.

1421 W 240th Street

Harbor City, Calif. 90710

Henry Westpfal & Co.

105 West 30th Street

New York, N.Y. 10001

The W. O. Hickok Mfg. Co.

Ninth and Cumberland Streets

Harrisburg, Pennsylvania 17105

Non-warping paste and other adhesives:

S. & W. Framing Supplies, Inc.

120 Broadway

Garden City Park, New York 11040

(Mail: P.O. Box 340)

Liquid and dry-ground hide glue:

Craftsman Wood Service Co.

1735 West Cortland Court

Addison, III. 60101

(Request catalog)

Planatol BB adhesive:

In the U.S.:

Gane Bros. & Lane, Inc.

European address:

Planatolwerk W. Hesselmann,

82 Rosenheim, West Germany

Leather, leather tools, etc.:

The Tandy Leather Company

P.O. Box 791

Fort Worth, TX 76101

(184 stores throughout the country)

Hard-to-find tools, mallets, knives, etc.:

Brookstone Company

119 Brookstone Bldg.

Peterborough, New Hampshire 03458

(Catalog sent free on request)

Printing presses, type, etc.:

The Kelsey Company

Meriden, Connecticut 06450

Acme Type

1720 North Marshfield

Chicago, Ill. 60622

(Catalog $2, refundable)

Type foundry, Pacific Coast:

Mackenzie & Harris, Inc.

480 Second Street

San Francisco, Calif. 94107

Other sources of bookbinding supplies:

Basic Crafts Co.

1201 Broadway

New York, N.Y. 10001

Paxton Equipment Supply

7401 South Pulaski Road

Chicago, Illinois 60629

A. I. Friedman, Inc.

44 West 18th Street

New York, N.Y. 10011

1. Tools and Adhesives

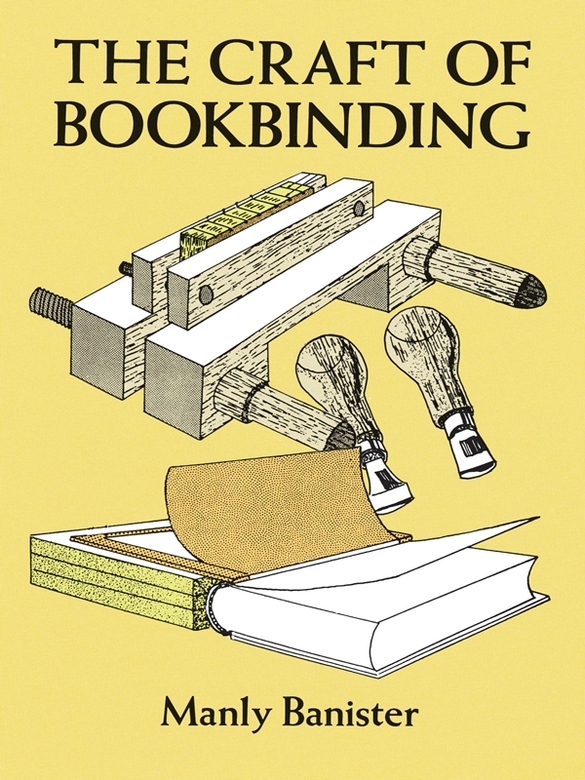

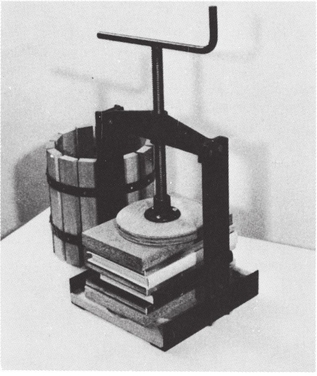

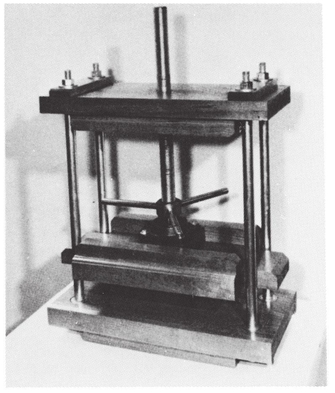

What tools do you really need? To start your bookbinding career, you need a lying press and plow with backing boards and some kind of a simple book press (Illus. 4 and 1314). You can buy such tools ready-made (see list of suppliers on page 159), or you can make them yourself, or have them made from the drawings provided. You do not need a wide outlay of such tools as knives and hammers. If you have them, use them. Otherwise, make do with what you have.

Illus. 4A fruit press makes a good book press. The fruit cage is not usedit is present in the photo for identification only.

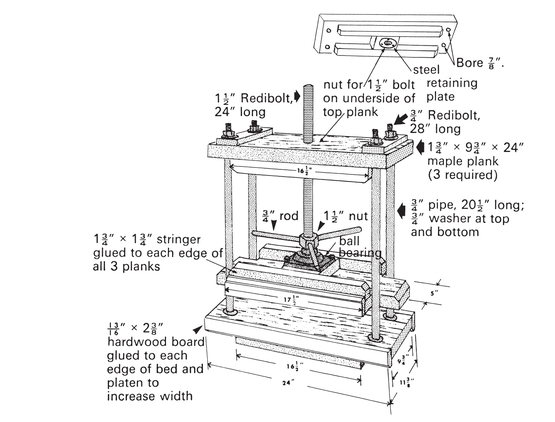

Present-day availability of the Redibolt (threaded rod) has vastly simplified the home-shop construction of bookbinding equipment. Redibolts up to  diameter by 3 feet in length are available in hardware stores. (In metric countries, threaded rods are sold by millimetre lengths.) Larger sizes can be purchased from an industrial hardware dealer. Sizes up to

diameter by 3 feet in length are available in hardware stores. (In metric countries, threaded rods are sold by millimetre lengths.) Larger sizes can be purchased from an industrial hardware dealer. Sizes up to  -inch diameter come in 3-foot lengths. Redibolts of 2-inch diameter and up come in 12-foot lengths, but these are larger than needed and are not to be considered. Purchase nuts required for the size of rod at the same time you buy the Redibolts.

-inch diameter come in 3-foot lengths. Redibolts of 2-inch diameter and up come in 12-foot lengths, but these are larger than needed and are not to be considered. Purchase nuts required for the size of rod at the same time you buy the Redibolts.

Illus. 5The standing press. This one was made by the author from maple planks, using a 1  -inch Redibolt (threaded rod) for a press screw. It is an ideal press for the classroom or advanced amateur.

-inch Redibolt (threaded rod) for a press screw. It is an ideal press for the classroom or advanced amateur.

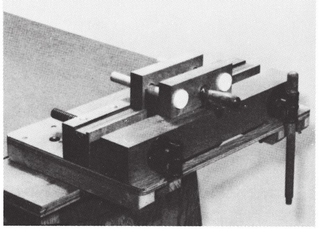

LYING PRESS AND PLOW. (Illus. 78). As a lying press only, it is used to hold the book in various forwarding operations (forwarding = all the steps involved in bookbinding from tearing down the book up to but not including finishing or titling).

With the plow, it is used to trim the edges of books. With backing boards, it becomes a backing press. Note the backing boards in Illus. 8. Old-time bookbinders used boards that tapered in thickness from the beveled edge to the bottom edge and are difficult to hold while adjusting the book in the press. The boards shown rest on the tub and cannot fall through. Instead of tapering the thickness, strips of  -inch hardboard are glued to the sides at the height of the cheek of the press. The purpose of these strips is the same as that of tapering the boardsto bring the pressure of the press to bear only against the line of backing and not against the entire book. Otherwise, boards narrower than the book would mark an unsightly crease across the endpapers.

-inch hardboard are glued to the sides at the height of the cheek of the press. The purpose of these strips is the same as that of tapering the boardsto bring the pressure of the press to bear only against the line of backing and not against the entire book. Otherwise, boards narrower than the book would mark an unsightly crease across the endpapers.

Illus. 6Construction details, the standing press.

Maple is recommended for all construction, but other hardwoods, where available, may be used: birch, beech, cherry, etc.

To adapt the plane blade to the plow, the areas to be drilled and cut must first be heated cherry red with a torch or in a gas flame and allowed to cool slowly in the air. The blade can then be drilled and sawed, after which it is again heated cherry red and plunged into water to harden. To temper, place in a kitchen oven at 300 F. (148 C.) for one hour, then quench again in water.

Illus. 7A home-made lying press and plow on its modern adaptation of the tub.

PRESSING BOARDS. (Illus. 2 and 14). Plain pressing boards and grooving boards (to make the French groove at the hinge of the book) are needed. Plain pressing boards can be simply pieces of plywood faced with untempered hardboard. If

diameter by 3 feet in length are available in hardware stores. (In metric countries, threaded rods are sold by millimetre lengths.) Larger sizes can be purchased from an industrial hardware dealer. Sizes up to

diameter by 3 feet in length are available in hardware stores. (In metric countries, threaded rods are sold by millimetre lengths.) Larger sizes can be purchased from an industrial hardware dealer. Sizes up to  -inch diameter come in 3-foot lengths. Redibolts of 2-inch diameter and up come in 12-foot lengths, but these are larger than needed and are not to be considered. Purchase nuts required for the size of rod at the same time you buy the Redibolts.

-inch diameter come in 3-foot lengths. Redibolts of 2-inch diameter and up come in 12-foot lengths, but these are larger than needed and are not to be considered. Purchase nuts required for the size of rod at the same time you buy the Redibolts.

-inch Redibolt (threaded rod) for a press screw. It is an ideal press for the classroom or advanced amateur.

-inch Redibolt (threaded rod) for a press screw. It is an ideal press for the classroom or advanced amateur. -inch hardboard are glued to the sides at the height of the cheek of the press. The purpose of these strips is the same as that of tapering the boardsto bring the pressure of the press to bear only against the line of backing and not against the entire book. Otherwise, boards narrower than the book would mark an unsightly crease across the endpapers.

-inch hardboard are glued to the sides at the height of the cheek of the press. The purpose of these strips is the same as that of tapering the boardsto bring the pressure of the press to bear only against the line of backing and not against the entire book. Otherwise, boards narrower than the book would mark an unsightly crease across the endpapers.