First published 2014 in Great Britain and the United States by ISTE Ltd and John Wiley & Sons, Inc.

Apart from any fair dealing for the purposes of research or private study, or criticism or review, as permitted under the Copyright, Designs and Patents Act 1988, this publication may only be reproduced, stored or transmitted, in any form or by any means, with the prior permission in writing of the publishers, or in the case of reprographic reproduction in accordance with the terms and licenses issued by the CLA. Enquiries concerning reproduction outside these terms should be sent to the publishers at the undermentioned address:

ISTE Ltd

27-37 St Georges Road

London SW19 4EU

UK

www.iste.co.uk

John Wiley & Sons, Inc.

111 River Street

Hoboken, NJ 07030

USA

www.wiley.com

ISTE Ltd 2014

The rights of Franois Templier to be identified as the author of this work have been asserted by him in accordance with the Copyright, Designs and Patents Act 1988.

Library of Congress Control Number: 2014941990

British Library Cataloguing-in-Publication Data

A CIP record for this book is available from the British Library

ISBN 978-1-84821-575-7

Introduction

I.1. Revolution(s)

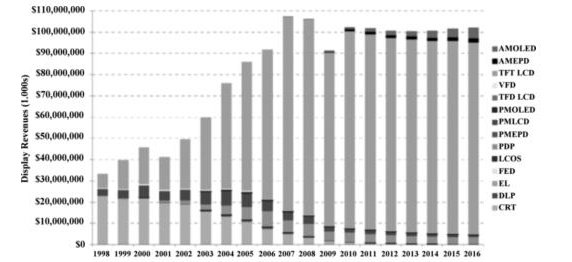

During the last decade, a revolution has happened in the display industry (). In fact, not only one, but two revolutions. The first revolution is the fade-out of the cathode ray tube (CRT). Like the giant meteor hitting planet earth 65 million years ago led to eradication of dinosaurs, the giant wave of flat-panel displays pushed out irremediably the 100-year old CRT.

Display market 19902012 [NTA 14].

The other revolution is that in the meantime, the total display market rose from a cushy ~30-billion to a tremendous 100-billion dollar market. This is illustrated by the explosion of display application we have seen around us, at home (how many TV screens in the house in addition to the former single big TV in the living room?), in the car, or simply with all our digital wearable companions. During this second revolution; a very particular type of display has discreetly emerged and took a piece of the cake: microdisplays. A small piece of the market (so far), a small size, but definitely present.

I.2. Definition of microdisplays

Microdisplays can be defined as having a diagonal of around 1 inch or less. As a consequence, this means that they require an additional optical magnification system to be seen by the human eye. The system would depend on the use. In the case of near-to-eye application, such as head-mounted display (HMD) and head-up display (HUD), the system projects a virtual image, by collimating the light from the microdisplay and projecting the image near infinity. For projector applications, the collimated optics role is to make an enlarged, real image of the microdisplay on a physical diffusing screen.

One objective of microdisplays is to deliver the same image quality as conventional, larger-size displays. One of the main attributes to image quality is the definition, namely the total number of pixels constituting the image. If we consider the 1,080 p high-definition standard (1,080 lines and 1,920 columns), the color pixel-pitch will be around 460 m in the case of a 40 in diagonal TV, and around 58 m in the case of 5 in display from a high-end smartphone. In the latter case, considering a quad color arrangement, this corresponds to an elemental pixel pitch of around 29 m. This pixel pitch is today the smallest that can be obtained with the conventional active-matrix techniques using thin-film transistor (TFT) technology on large-area glasses, where the minimum feature size provided by the patterning process is generally around 2 m.

To achieve the same 1,080 p resolution on a microdisplay of say 0.5 in, the pixel pitch needs to be an order of less magnitude, namely much less than 10 m. The main consequence of such small pixel-size is that they cannot be fabricated with conventional TFT active-matrix technologies. Actually, active matrix for microdisplays requires complementary metal-oxide-semiconductor (CMOS) integrated circuit (IC) technologies built on monocrystalline silicon, which provides the smallest feature size, now down to a few nanometer for advanced circuits). Only with such technologies, pixel pitches of a few microns can be obtained. Besides the difference in active matrix technology, there is therefore also a strong difference in the manufacturing model (and cost model) between microdisplays and conventional, medium/large-size displays. Conventional displays are fabricated on large area glass (up to 3 3 m) and feature pixel size of typically 30300 m ().

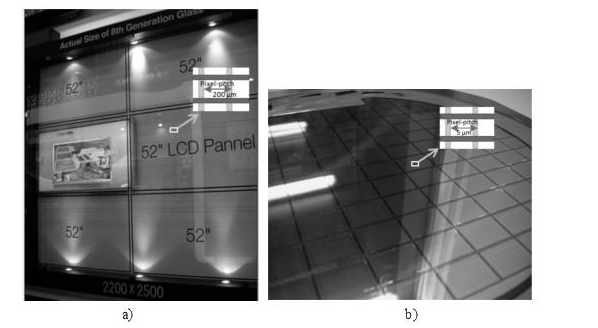

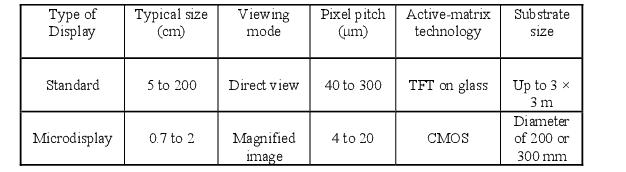

a) 2.2 2.5 m glass substrate with six TFT active matrices 52 in. TVs. Inset is a magnified view of a pixel. b) (by courtesy of Ghent University) 200 mm silicon wafer with CMOS circuit consisting of active matrices for LCOS microdisplays. Inset is a magnified view of a pixel

summarizes main differences between standard-type displays and microdisplays.

Main differences between standard-type and microdisplays

In summary, a microdisplay can be defined as a display needing magnifying optics to be seen, and having an IC chip as active matrix.

There might be an exception to this definition. Indeed some transmissive liquidcrystal display (LCD) microdisplays used for many years in projectors do have a small size (~0.5 to 2 in) but do not have an IC active matrix. They are fabricated using the so-called high-temperature polysilicon (HTPS) technology, which consists of making active matrix with TFTs [MOR 86]. It uses TFTs, however the approach is very different to the classical a-Si or low-temperature polysilicon (LTPS) TFT processes, which are made on very large-area, inexpensive borosilicate glass plates, and where the minimum feature size is ~2 m or more. HTPS, as its name suggests, requires a high-temperature process: actually, it consists of depositing amorphous silicon at a few hundred degrees, and later in the process to convert it into polysilicon by performing an annealing step at a high temperature: 1000C. Such a high temperature prohibits the use of conventional borosilicate glass, but imposes highly stable and transparent quartz substrates. These substrates are much more expensive, and therefore are relevant only for smaller sizes, actually quartz wafers with the same size as silicon counterparts (200 or 300 mm in diameter) used for CMOS circuits. Having the same size and shape as silicon wafers, these quartz wafers give access to IC manufacturing tools and design rules, therefore very highresolution lithography is feasible, and pixel pitches as small as those obtained with IC active matrices can be made, namely ~10 m or less. In the end, HTPS is indeed also microdisplays, since its active matrix is definitely made using IC technologies, though the substrate is not silicon, but quartz.

I.3. A brief history and overview of microdisplays

The need for microdisplays initially came from a need for bigger displays. In fact, at the time when CRT was the only display technology, it was very difficult to increase the image size and for a long time CRT TVs for household receivers did not exceed 2530 in. Therefore, TV manufacturers were looking for solutions to increase image size, and application of projection technology was quite straightforward. CRT projection provided larger images but with a main drawback: a loss in luminance. Then came the need for the so-called spatial light modulators (SLM), a two-dimensional (2D) optical modulator, which would impress 2D modulation onto an optical beam. Modulation could be applied on phase, amplitude, or other. In the case of amplitude modulation, such system would perfectly fit for projecting an image.