James Morgan - The Toyota Product Development System

Here you can read online James Morgan - The Toyota Product Development System full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2006, publisher: Taylor and Francis, genre: Computer. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:The Toyota Product Development System

- Author:

- Publisher:Taylor and Francis

- Genre:

- Year:2006

- Rating:4 / 5

- Favourites:Add to favourites

- Your mark:

- 80

- 1

- 2

- 3

- 4

- 5

The Toyota Product Development System: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "The Toyota Product Development System" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

The Toyota Product Development System — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "The Toyota Product Development System" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

WE WOULD LIKE TO EXPRESS our deep and sincere appreciation to the many people who have contributed to this research. We are profoundly indebted to them.

We can never possibly repay the profound debt we owe to Mr. Mike Massaki, Mr. Uchi Okamoto, and Mr. Hiro Sugiura of Toyota. Massaki-san provided us with access and opportunity and Okamoto-san and Sugiurasan spent countless hours explaining the intricacies of Toyota vehicle development, while Mr. Miyadera answered many additional questions. We also gained many insights into Toyotas systems from American Toyota executives who have worked so hard to understand the true philosophy at the Toyota Technical Center, including Jim Griffith, Ed Mantey, Bruce Brownlee, and David Baxter.

We also owe a considerable debt to the many others at Toyota such as Mr. Uchiyamada, Mr. M. Terasaka, Mr. S. Yamaguchi, Mr. S. Nakao, Mr. K. Miyadera Mr. T. Yamashina, Mr. E. Gay, Mr. C. Royal, Mr. T. Buffeta, Dr. C. Couch, and Mr. B. Krinock and the many others who spent their time helping us in this research.

We are of course very grateful for the work that came before this and in a sense made this book possible. The now classic work of Dr. Jim Womack and Dr. Dan Jones, as well as the value stream mapping book and class by Mr. Mike Rother and Mr. John Shook inspired and informed this application to product development. The long stream of product development research at the University of Michigan provided a firm foundation, including the excellent work by Professor Durward Sobek, Dr. Pat Hammett, Dr. John Cristiano, Dr. Jay Baron, Professor Jack Hu, and especially for the path-breaking research of Dr. Allen Ward.

We are also very grateful to those who have provided ongoing assistance and feedback in this process such as Mr. John Shook and Mr. Stephen Hung, especially with value stream mapping.

Finally, and most especially we are grateful to our families. Jim thanks his wife Mary for her editorial input, continuing moral support, and patience and son Greg for patience beyond his years, support, and for the good luck charm that he loaned. Jeff thanks his wife Deb, son Jesse, and daughter Emma who provide a loving home to return to and put up with much time away traveling to spread the word of the Toyota Way.

Applying Value Stream Mapping to a Product Development Process: The PeopleFlo Manufacturing Inc. Case

by Dr. Drogosz John

PEOPLEFLO IS A SMALL START-UP COMPANY that designs and manufactures pumps for chemical, petrochemical, and food processing applications. The company was founded by a team of people committed to applying lean manufacturing philosophy and tools in a unique and comprehensive way. Starting with a clean slate, PeopleFlos management team designed a new product line and built every core business process into one interdependent lean enterprise. They developed patented technologies, simplified the product so that it could be flexibly built in lean cells, and met every major timing milestone.

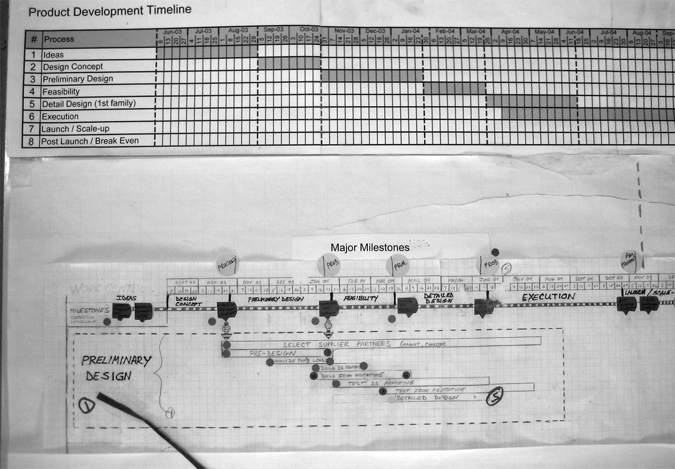

An essential part of the companys lean enterprise vision was to rethink how best to design new products. This meant slashing the typical product development cycle from three to four years in the pump industry down to less than one year. In addition, it meant achieving breakthroughs in design for setup reduction, design for cycle-time reduction, and design for inventory reduction. To achieve these goals, the company started with a clean sheet of paper and used the value stream mapping tool not only to detail the best way to design, validate, and launch production of a new pump product but also to manage the product development process. The first step was to start with a high-level map that showed high-level activities, key decisions, and integration points that were necessary to design a new pump. shows the major phases of the product development process and its milestones.

. High Level Product Development Map & Master Time Line

Once the high-level process map was defined, each process was mapped in more detail. The tasks and key information flows were delineated and timing was set for each task. shows the process architecture for the preliminary design phase.

. VSM of Preliminary Design Phase

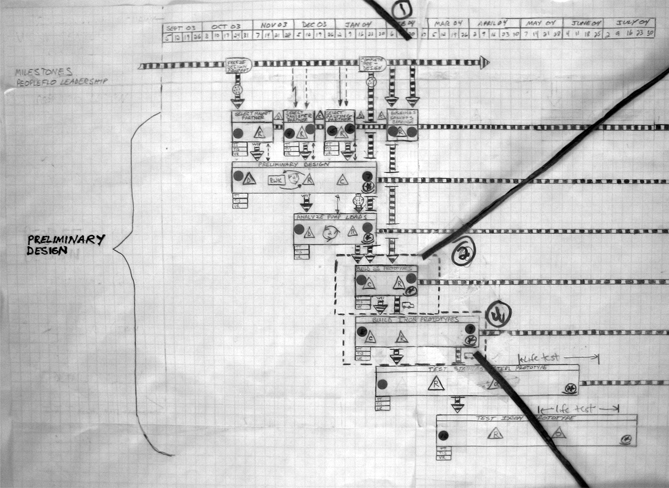

As part of the mapping activity, PeopleFlo incorporated several lean product development concepts into its development process. For example, activities were included that allowed design time to examine multiple alternatives (set-based concurrent engineering). In addition, reflection events were hard-coded into the plan to ensure that learning was captured all the way through the development process.

In addition to using the value stream map to define a new PeopleFlo product development process, company leaders used it as a visual program management tool. visual controls to highlight problems/opportunities and indicate program status.

. VSM Visual Controls

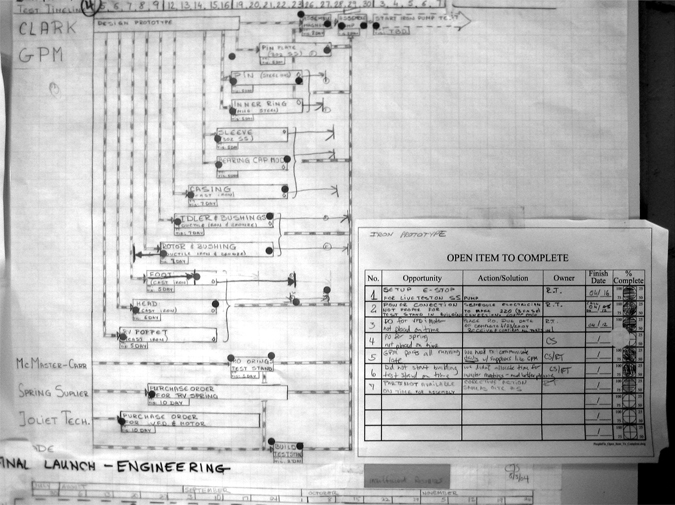

Teams held morning market meetings around the value stream map boards to report status. As illustrates, the program board showed current status regarding timing; red-dot visual indicators were placed directly on the map to indicate where issues were discovered. Any red dots required an immediate countermeasure. An open issues list was also posted at the VSM program board. In addition to acting as a rapid problem-solving tool, the list was also used to capture learning for improving future programs.

. Visual Controls and Open Issues List

As the product development cycle progressed, the team members continued to add new lower-level maps and include tasks and information flows that they had missed in creating the early-stage VSM. By the end of the first product development cycle, they had clearly documented the best way to create their first product family of shows the overall process architecture for PeopleFlos product development process.

. VSM Process Architecture for Pump Family 1

The development team is now using the value stream maps from the first family of pumps as the framework for the next family of pumps they are currently designing. The plan is to continue to apply the VSM approach to all future product development programs and customize this approach for each product familys specific requirements.

The result has been the development of a complete line of pumps that are in production in less than two years. In that time, PeopleFlo was able to design an innovative new generation product, with 50 percent fewer parts than comparable pumps and develop a unique fixturing system that eliminates changeover time on machining centers. A true one-piece flow cell without any changeover time allows flexible production. One cell has the ability to machine ten different pump parts, then paint, assemble, and ship 80 percent of parts sold, within 24 hours of receiving the orderunheard of within this industry. The cost for a comparable pump made by a conventional competitor was slashed by 50 percent.

The key to the success of this start-up business was a combination of people, process, and technology. Success factors included starting with a clean slate, assembling the right team of employees and business partners, and building one interdependent design-manufacturing system, with one set of goals, based on lean philosophy and tools.

Font size:

Interval:

Bookmark:

Similar books «The Toyota Product Development System»

Look at similar books to The Toyota Product Development System. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book The Toyota Product Development System and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.